Preparation method of dolutegravir micro powder

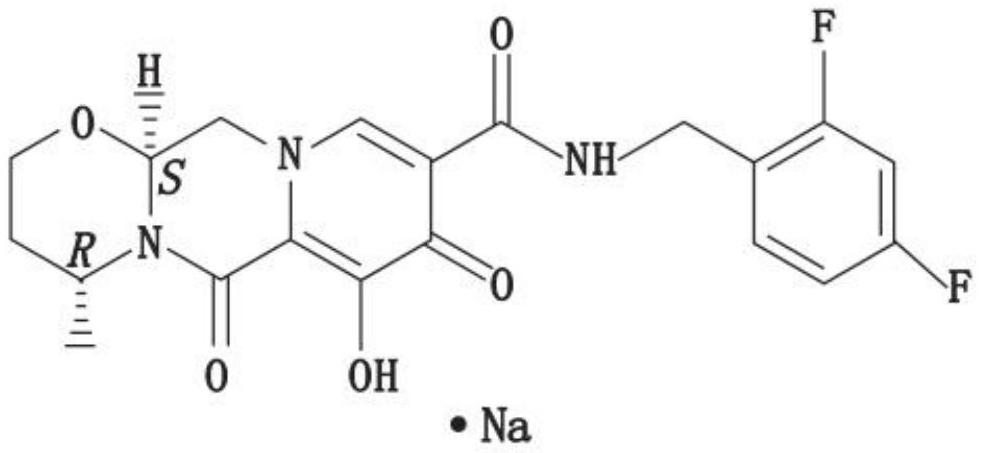

A technology of dolutegravir and micropowder, applied in the field of dolutegravir micropowder preparation, can solve the problems of poor solubility, affecting bioavailability, etc., and achieve the effect of lowering temperature and excellent ultrafine effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) In the reaction kettle, add solvent ethanol, dissolve the original powder of dolutegravir in ethanol, and prepare the ethanol solution of dolutegravir, wherein the concentration of dolutegravir is 50mg / ml.

[0027] (2) In another reaction kettle, an aqueous solution of sodium tripolyphosphate was prepared with pure water at a concentration of 1%.

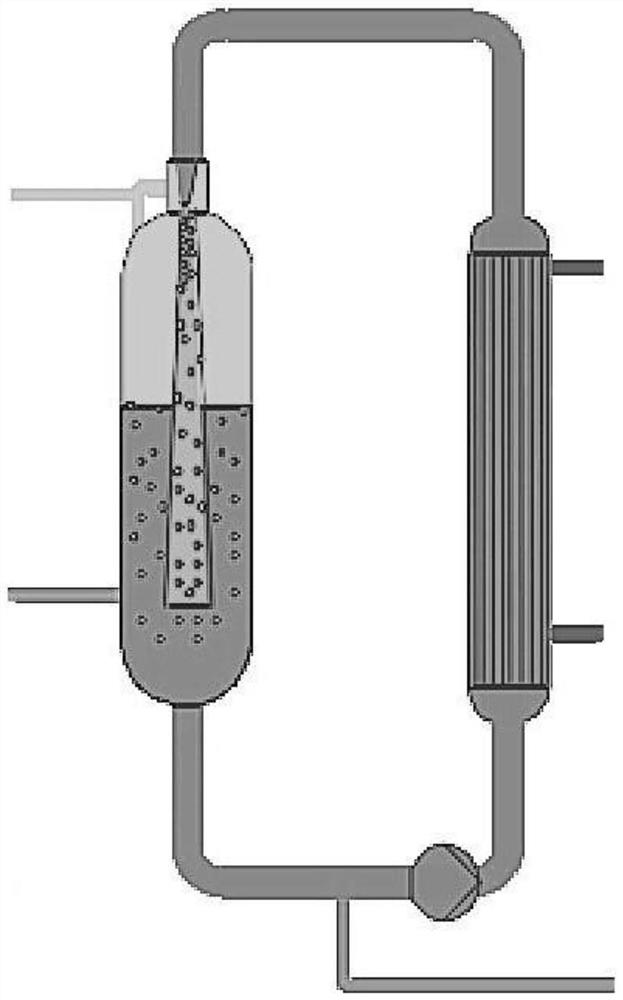

[0028] (3) Turn on the strong stirring of the above-mentioned saline solution, control the temperature at -10°C, and pass the ethanol solution of Dolutegravir through a high-pressure delivery pump through a jet mixer based on the Venturi effect set on the reaction kettle Spray into the saline solution and the reactor's jet mixer is immersed in the liquid phase of the reactor. Continue vigorous stirring for 60 min. Obtain dolutegravir suspension. Wherein the volume ratio of the saline solution and the ethanol solution of dolutegravir is 5:1, figure 1 It is a schematic diagram of a jet mixer based on the Venturi effect i...

Embodiment 2

[0031] (1) In the reaction kettle, add solvent ethanol, dissolve the original powder of dolutegravir in ethanol, and prepare the ethanol solution of dolutegravir, wherein the concentration of dolutegravir is 100mg / ml.

[0032] (2) In another reaction kettle, an aqueous solution of disodium edetate was prepared with pure water at a concentration of 5%.

[0033] (3) Turn on the strong stirring of the above-mentioned saline solution, control the temperature at 10°C, and spray the ethanol solution of dolutegravir through a high-pressure delivery pump through a jet mixer based on the Venturi effect installed on the reaction kettle. into the brine-containing solution, and the jet mixer of the reactor is immersed in the liquid phase of the reactor. Continue vigorous stirring for 30 min. Obtain dolutegravir suspension. Wherein the volume ratio of the saline solution and the ethanol solution of dolutegravir is 50:1, figure 1 It is a schematic diagram of a jet mixer based on the Vent...

Embodiment 3

[0036] (1) In the reaction kettle, add solvent ethanol, dissolve the original powder of dolutegravir in ethanol, and prepare the ethanol solution of dolutegravir, wherein the concentration of dolutegravir is 75mg / ml.

[0037] (2) In another reaction kettle, an aqueous solution of trisodium ethylenediamine disuccinate was prepared with pure water at a concentration of 3%.

[0038] (3) Turn on the strong stirring of the above-mentioned saline solution, control the temperature at 0°C, and spray the ethanol solution of dolutegravir through a high-pressure delivery pump through a jet mixer based on the Venturi effect installed on the reaction kettle. into the brine-containing solution, and the jet mixer of the reactor is immersed in the liquid phase of the reactor. Continue vigorous stirring for 45 min. Obtain dolutegravir suspension. Wherein the volume ratio of the saline solution and the ethanol solution of dolutegravir is 25:1, figure 1 It is a schematic diagram of a jet mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com