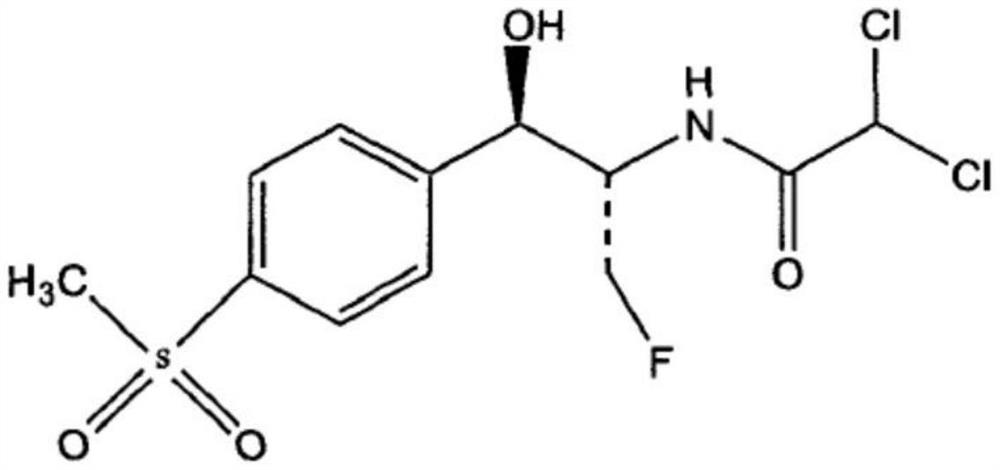

A kind of method for preparing florfenicol

A technology of florfenicol and reaction kettle, which is applied in the field of preparation of florfenicol, can solve the problems of poor solubility, affecting bioavailability, difficulty in obtaining ultrafine powder products, etc., and achieves the effect of obvious crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

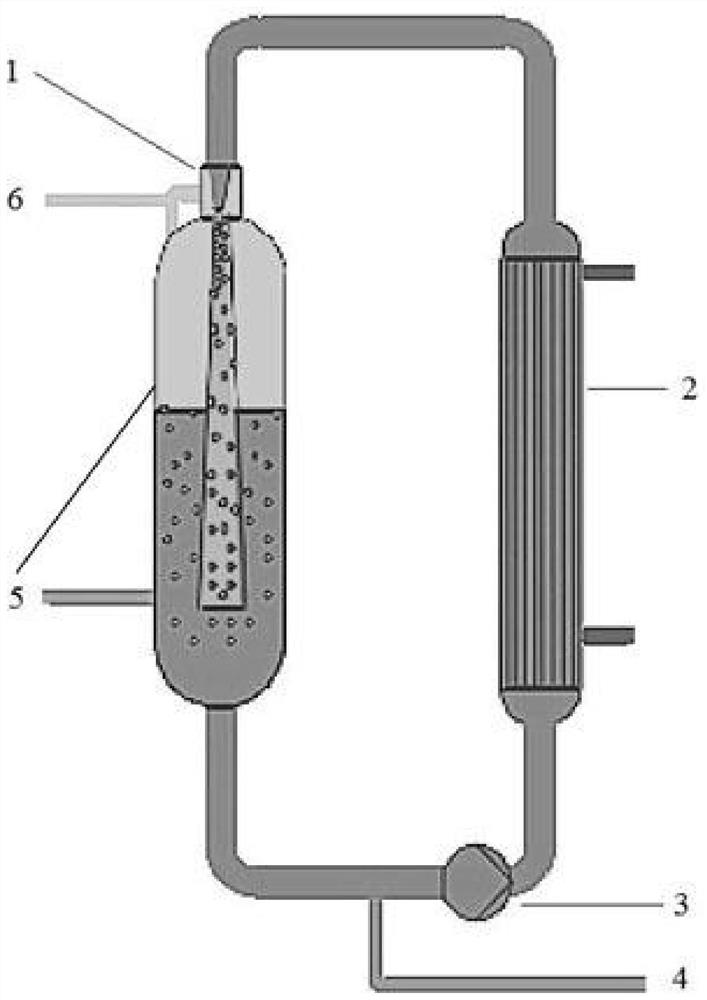

[0026] (1) In the reaction kettle, add the solvent dimethylformamide (DMF), dissolve the original powder of Florfenicol in DMF, and prepare the DMF solution of Florfenicol, wherein the concentration of Florfenicol is 50mg / ml.

[0027] (2) In another reaction kettle 5, add an aqueous aluminum sulfate solution prepared by pure water through the material feed port 6, wherein the salt concentration is 10%.

[0028] (3) Turn on the strong agitation of the aluminum-containing salt solution, control the temperature at -10°C through the heat exchanger 2, and transfer the DMF solution of Florfenicol through the high-pressure delivery pump 3 to the reactor based on the reactor 5. The jet mixer 1 of the Venturi effect is sprayed into the aluminum-containing brine solution, and the jet mixer 1 of the reactor is immersed in the liquid phase of the reaction vessel 5 . Continue vigorous stirring for 60 min. A suspension of florfenicol was obtained. Wherein the volume ratio of the aluminu...

Embodiment 2

[0031] (1) In the reactor, add solvent dimethylformamide (DMF), dissolve the original powder of Florfenicol in DMF, and prepare the DMF solution of Florfenicol, wherein the concentration of Florfenicol is 100mg / ml.

[0032] (2) In another reactor 5, add an aqueous alum solution prepared with pure water through the material feed port 6, wherein the salt concentration is 1%.

[0033] (3) Turn on the strong stirring of the aluminum-containing salt solution, control the temperature at 10°C through the heat exchanger 2, and transfer the DMF solution of Florfenicol through the high-pressure delivery pump 3 through the Venturi-based The jet mixer 1 of the Li effect is sprayed into the aluminum-containing salt solution, and the jet mixer 1 of the reactor is immersed in the liquid phase of the reactor. Continue vigorous stirring for 30 min. A suspension of florfenicol was obtained. Wherein the volume ratio of the aluminum-containing salt solution to the DMF solution of Florfenicol ...

Embodiment 3

[0036] (1) In the reaction kettle, add the solvent dimethylformamide (DMF), dissolve the former powder of Florfenicol in DMF, and prepare the DMF solution of Florfenicol, wherein the concentration of Florfenicol is 75mg / ml.

[0037] (2) In another reaction kettle 5, an aqueous aluminum sulfate solution prepared with pure water is added through the material feed port 6, wherein the salt concentration is 5%.

[0038] (3) Turn on the strong agitation of the aluminum-containing salt solution, control the temperature at 0°C through the heat exchanger 2, and transfer the DMF solution of Florfenicol through the high-pressure delivery pump 3 through the Venturi-based The jet mixer 1 of the Li effect is sprayed into the aluminum-containing salt solution, and the jet mixer 1 of the reactor is immersed in the liquid phase of the reactor. Continue vigorous stirring for 60 min. A suspension of florfenicol was obtained. Wherein the volume ratio of the aluminum-containing salt solution t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com