A novel preparation method for preparing Florfenicol crystals

A florfenicol and a new type of technology are applied in the field of new preparation of florfenicol crystals, which can solve the problems of inconvenient application of injections, difficult large-scale application, unreliable safety and the like, and achieve the effect of ultramicronization , strengthen the collision, the effect of excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

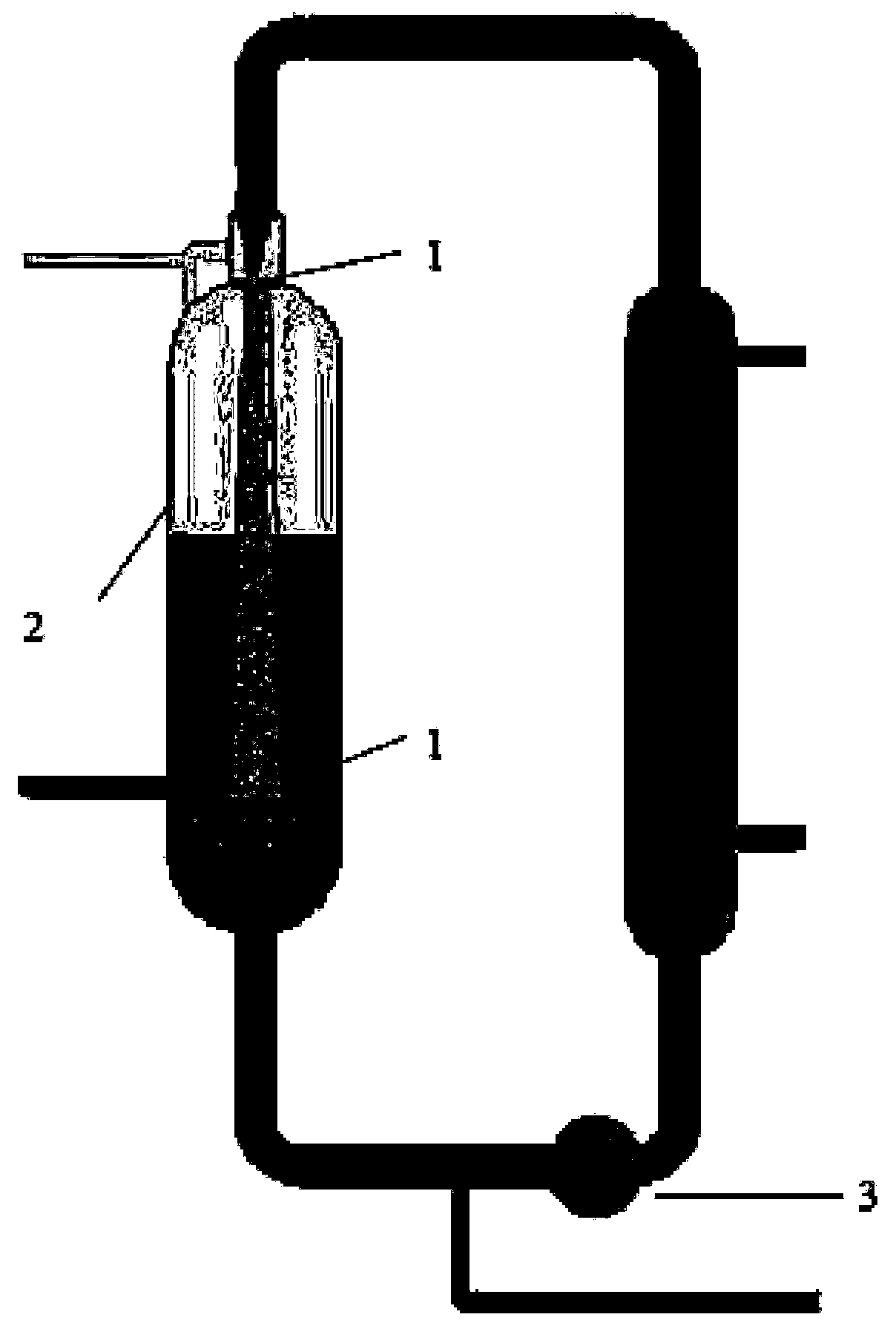

[0028] (1) In the reaction kettle 2, add solvent tetrahydrofuran, dissolve the former powder of florfenicol in tetrahydrofuran, and prepare a tetrahydrofuran solution of florfenicol, wherein the concentration of florfenicol is 30mg / ml.

[0029] (2) In another reaction kettle 2, an anti-solvent aqueous solution is prepared, which contains ethanol at a concentration of 5% and sodium hyaluronate at a concentration of 0.5%.

[0030] (3) The anti-solvent aqueous solution in step 2 is started with strong stirring, controlled at a temperature of -20 ° C, and the tetrahydrofuran solution of florfenicol is quickly pumped into the liquid surface of the anti-solvent aqueous solution through the high-pressure delivery pump 3. The opposite jet outlet 1 and the flow velocity at the outlet pipe is greater than 3 m / s. Continue vigorous stirring for 60 min. A suspension of florfenicol was obtained. Wherein the volume ratio of the anti-solvent aqueous solution to the tetrahydrofuran solution ...

Embodiment 2

[0033] (1) In reaction kettle 2, add solvent tetrahydrofuran, dissolve the former powder of florfenicol in tetrahydrofuran, prepare the tetrahydrofuran solution of florfenicol, wherein the concentration of florfenicol is 80mg / ml.

[0034] (2) In another reaction kettle 2, prepare an aqueous anti-solvent solution, which contains ethanol at a concentration of 1%; contains sodium hyaluronate 0.1%.

[0035] (3) The anti-solvent aqueous solution in step 2 is turned on for strong stirring, controlled at a temperature of 0°C, and the tetrahydrofuran solution of florfenicol is quickly pumped under the liquid surface of the anti-solvent aqueous solution through the high-pressure delivery pump 3, and a hedge is used. Type jet outlet 1 and the flow velocity at the outlet pipe is greater than 3 m / s. Continue vigorous stirring for 30 min. A suspension of florfenicol was obtained. Wherein the volume ratio of the anti-solvent aqueous solution to the tetrahydrofuran solution of Florfenicol ...

Embodiment 3

[0038] (1) In reaction kettle 2, add solvent tetrahydrofuran, dissolve the former powder of florfenicol in tetrahydrofuran, prepare the tetrahydrofuran solution of florfenicol, wherein the concentration of florfenicol is 50mg / ml.

[0039] (2) In another reaction kettle 2, an anti-solvent aqueous solution is prepared, which contains ethanol at a concentration of 3%; contains sodium hyaluronate 0.3%.

[0040] (3) The anti-solvent aqueous solution in step 2 is started to stir vigorously, controlled at a temperature of -10°C, and the tetrahydrofuran solution of florfenicol is quickly pumped into the liquid surface of the anti-solvent aqueous solution through the high-pressure delivery pump 3. The opposite jet outlet 1 and the flow velocity at the outlet pipe is greater than 3 m / s. Continue vigorous stirring for 60 min. A suspension of florfenicol was obtained. Wherein the volume ratio of the anti-solvent aqueous solution to the tetrahydrofuran solution of Florfenicol is 25:1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com