Intelligent injection pump and infusion pump detection system

A detection system and syringe pump technology, applied in the direction of pressure infusion, devices introduced into the body, and drug devices, etc., can solve the problems of poor detection record quality, low measurement efficiency, and cumbersome measurement process, so as to improve efficiency and save time As well as manpower, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

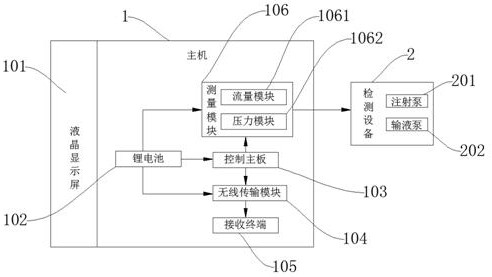

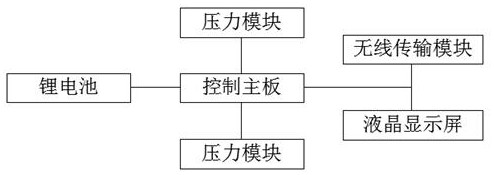

[0033] Such as Figure 1-Figure 2 As shown, the intelligent syringe pump infusion pump detection system includes a host 1, a measurement module 106 and a detection device 2. The measurement module 106 is installed in the host 1, and the measurement module 106 includes a flow module 1061 and a pressure module 1062. A lithium battery 102, a wireless transmission module 104, and a receiving terminal 105 are also installed in the host 1, a liquid crystal display 101 and a control board 103 are installed on the outside of the host 1, and the detection device 2 is arranged on one side of the host 1 , the detection device 2 includes a syringe pump 201 and an infusion pump 202, through the liquid crystal display 101, the flow module 1061, the pressure module 1062, the control board 103, the wireless transmission module 104 and the The design of the receiving terminal 105 not only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com