Mining wet dust removal method

A wet dust removal and mining technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of insufficient dust treatment, easy blockage of dust removal, and difficult maintenance of devices, and reduce the probability of secondary dust. , easy to maintain, to ensure the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

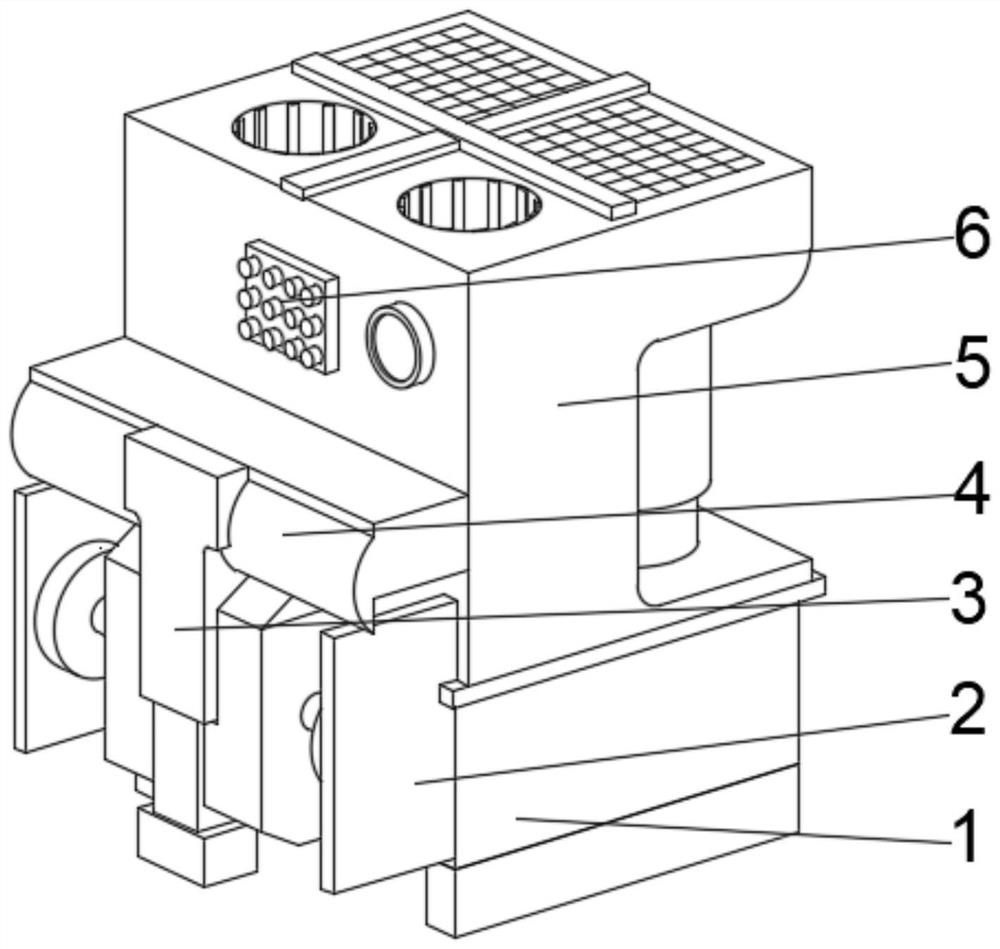

[0040] see Figure 1-6 , the present invention provides a technical solution: a wet dust removal method for mining, comprising a water storage tank 1, a circulation box 2 is fixedly connected to the top of the left outer wall of the water storage tank 1, and a water outlet is provided at the middle of the top of the left outer wall of the circulation box 2 The top of the pipe 3 and the water outlet pipe 3 are connected with the adjustment piece 4, and the outer wall of one side of the adjustment piece 4 is fixedly connected with the dust removal device 5, the bottom of the dust removal device 5 is fixedly connected with the water storage tank 1, and the middle part of the left outer wall of the dust removal device 5 is fixedly connected There are control panels6.

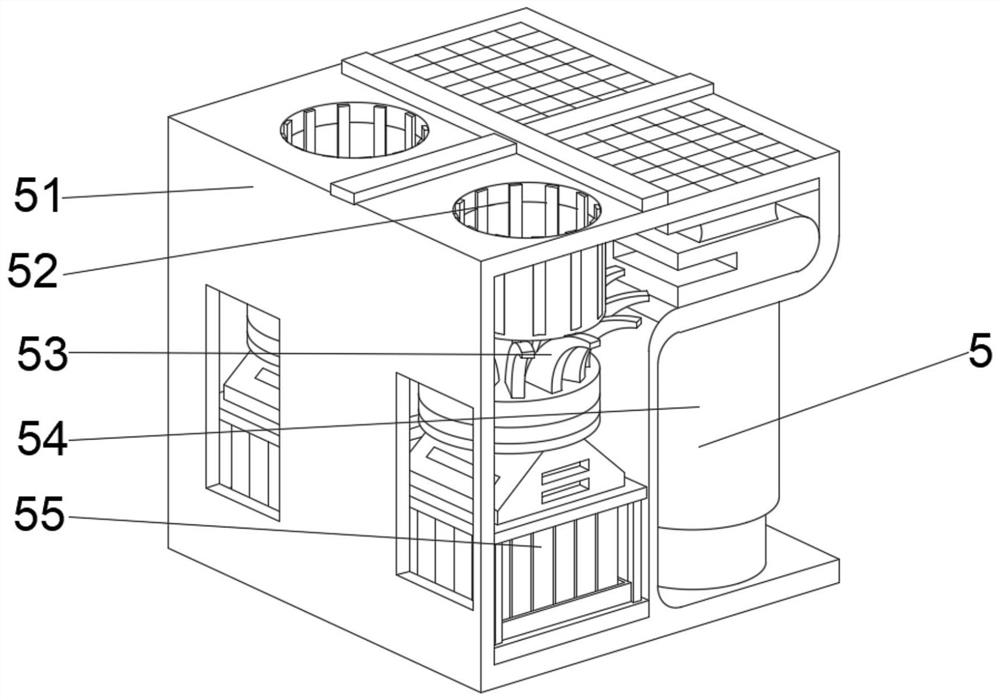

[0041] Wherein, the dedusting device 5 comprises a dedusting frame 51, the top left side of the dedusting frame 51 is provided with a dust collecting port 52, the two sides of the inner chamber bottom of the dedusti...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using mine wet dust removal, step 1: install the equipment, connect the adjustment member 4 with the circulation box 2, and connect the circulation box 2 Insert the middle part of the water storage tank 1, and fill the inside of the water storage tank 1 with water;

[0048] Step 2: When starting the equipment, connect the fan installed inside the dust removal frame 51 with the dust collection port 52, drive the dust to enter the inside of the filter mechanism 55 through the positioning of the support plate 53, connect the humidifying mechanism 54 with the filter mechanism 55, and carry out the rapid removal of dust clean up;

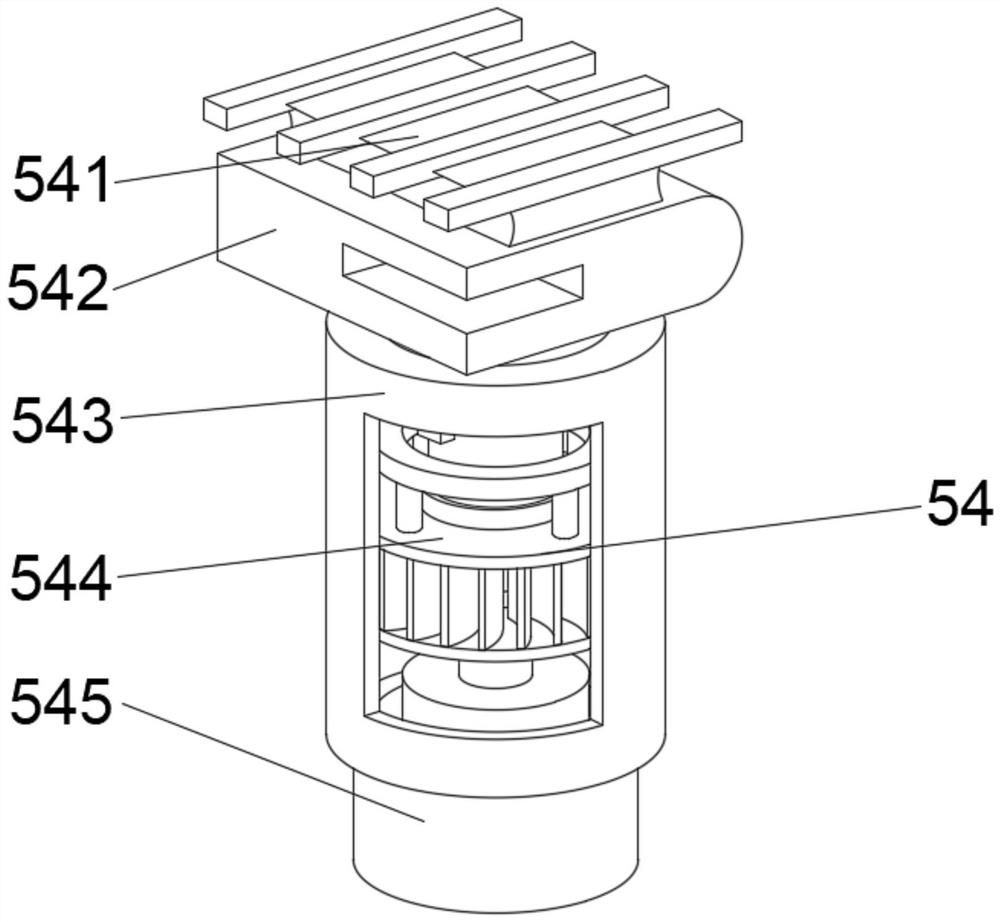

[0049] Step 3: Transport the internal water quantitatively to the interior of the humidifying cylinder 543 through the water blocking pipe 545, use the reinforcing body 544 to gather the water in the humidifying cylinder 543 driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com