Blending and proportioning device for fertilizer production

A blending and fertilizer technology, used in transportation and packaging, mixer accessories, chemical instruments and methods, etc., can solve the problems of easy residue, long mixing and mixing time, inconvenient cleaning, etc., to save time, improve mixing efficiency, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

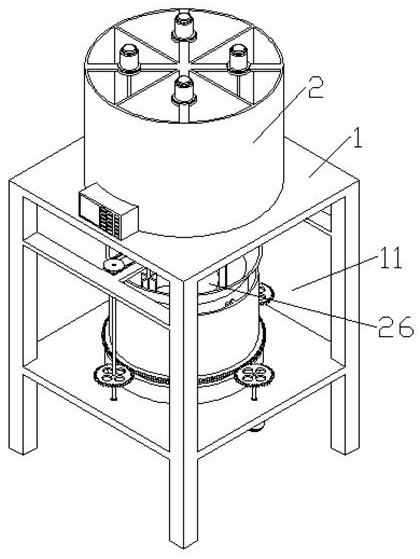

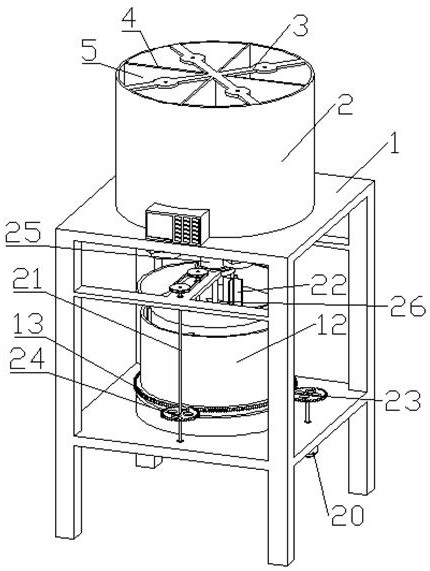

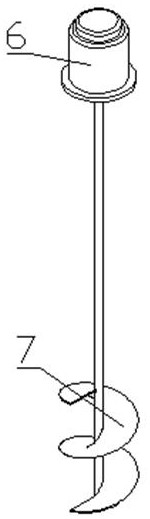

[0016] like Figure 1-5 As shown, a blending and proportioning device for fertilizer production includes No. 2 support frame 1, material storage box 2, No. 1 support frame 3, partition plate 4, material storage chamber 5, No. 1 speed regulating motor 6, No. 1 Auger 7, No. 1 discharge pipe 8, No. 1 stop valve 9, controller 10, stirring part 11, the top of the No. 2 support frame 1 is fixed with a material storage box 2, and the top of the No. A support frame 3, and a plurality of partitions 4 are fixed inside, the interior of the storage box 2 is divided into a plurality of storage chambers 5 by the partitions 4, and a plurality of No. 1 tones are fixed on the top of the No. 1 support frame 3. Speed motor 6, a No. 1 auger 7 is respectively fixed at the bottom of the rotating shaft of each No. 1 speed-regulating motor 6, and a plurality of No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com