New energy automobile motor stator connecting wire welding machine

A new energy vehicle, motor stator technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of inconvenient adjustment of the welding head, and achieve the effect of convenient installation and disassembly, easy replacement or cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

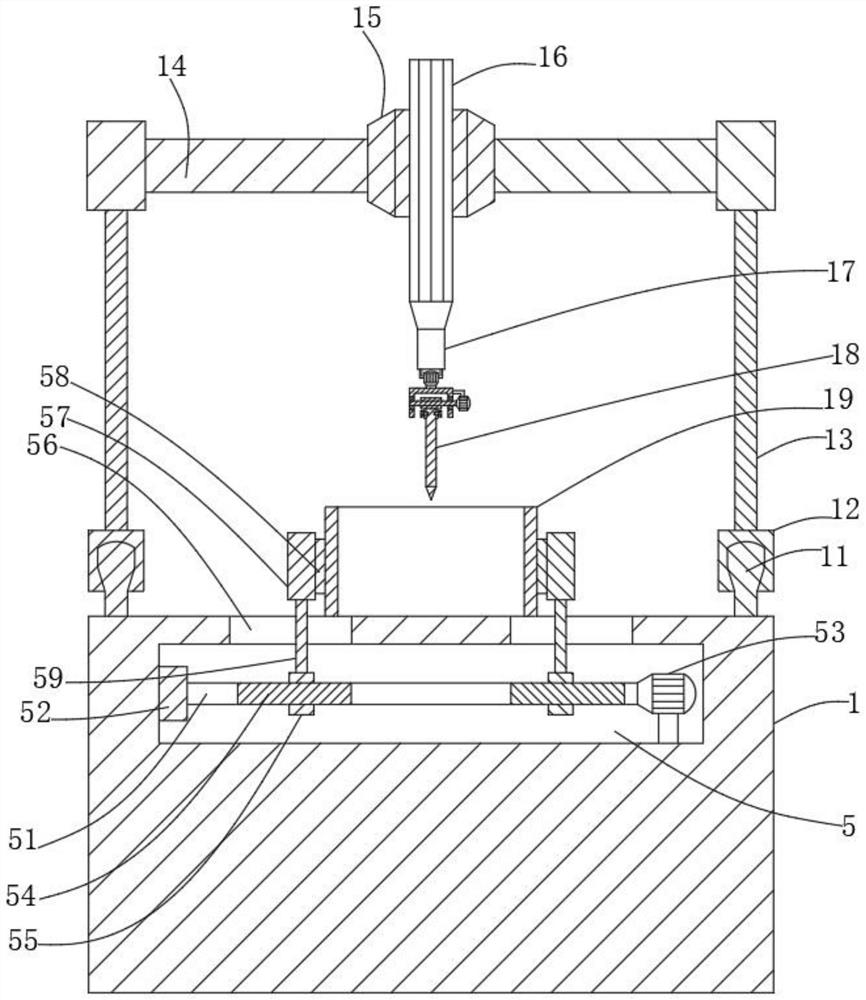

[0043] see figure 1 , this embodiment further describes other embodiments, a new energy vehicle motor stator connection wire welding machine, including an operating table 1, a first guide rail 11 is fixed on the operating table 1, and a first guide rail is slidably arranged on the first guide rail 11 A pair of 12, a support rod 13 is fixed on the first guide rail pair 12, a second guide rail 14 is fixed on the support rod 13, a second guide rail pair 15 is slidably arranged on the second guide rail pair 15, and a cylinder body is fixed on the second guide rail pair 15 16. The piston rod 17 of the cylinder 16 is provided with a welding joint 18, and the stator body 19 is placed on the console 1.

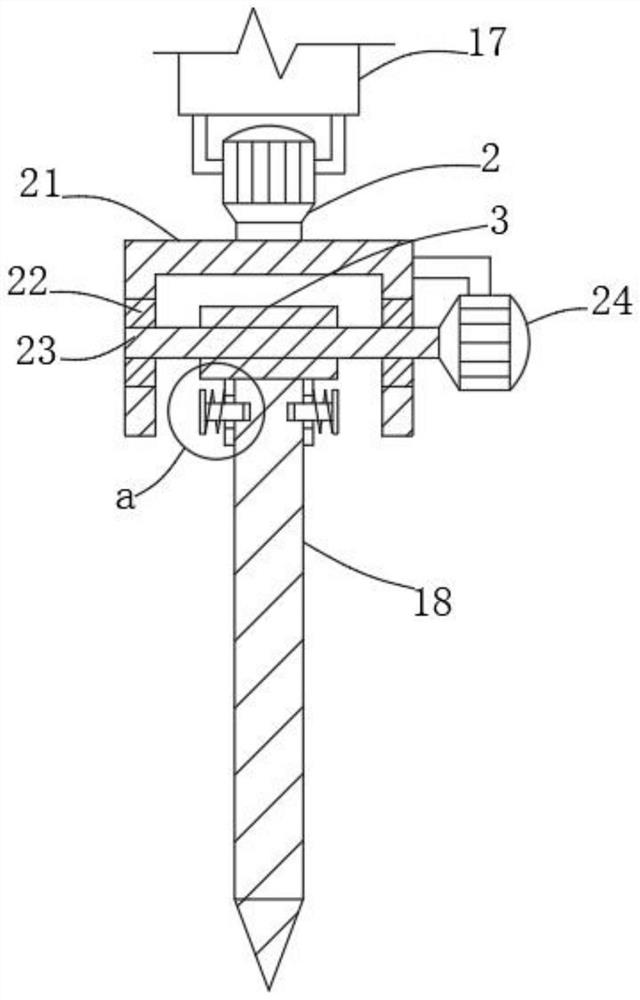

[0044] see figure 1 and figure 2 , the first motor 2 is fixed on the piston rod 17, and the frame body 21 is fixed on the first motor 2, and the welding joint 18 can be installed and docked.

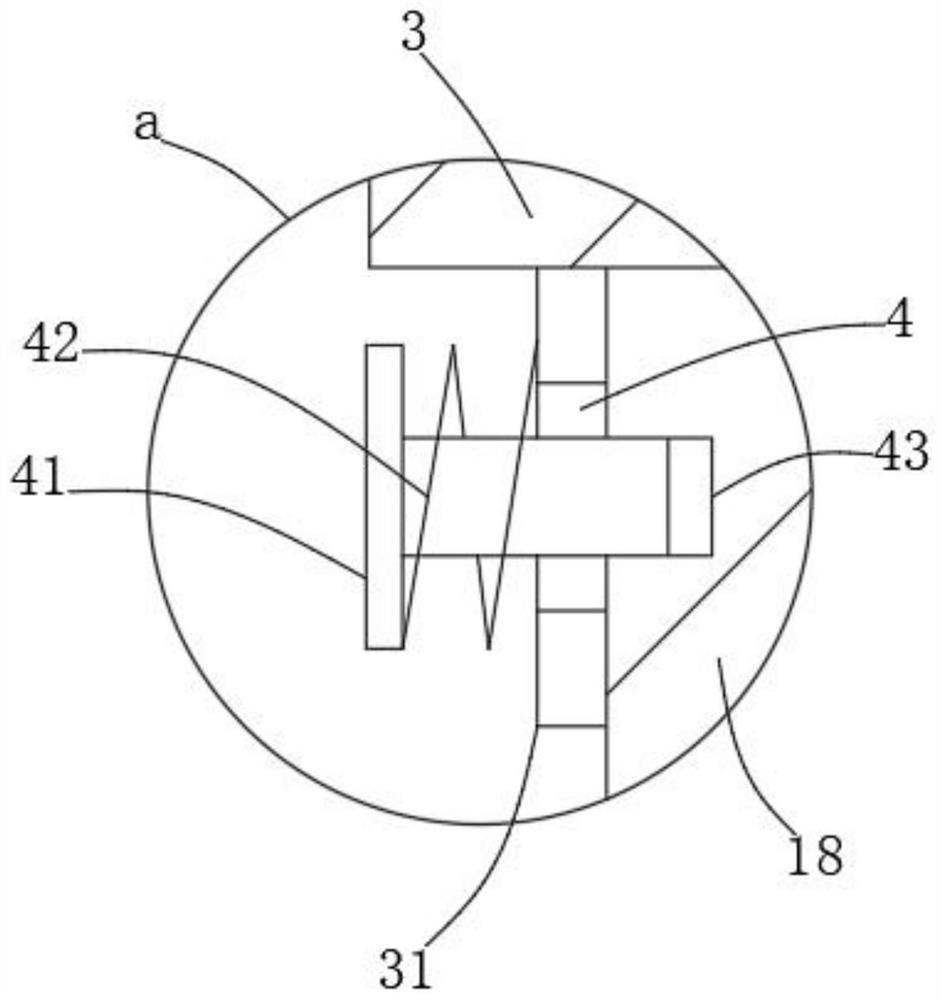

[0045] see figure 1 and figure 2 , the frame body 21 is fixedly embedded with a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com