Integrated beam component prefabricated reinforcement framework production and formwork connection auxiliary tool

A technology of steel skeleton and auxiliary tooling, which is applied to formwork/formwork/work frame, on-site preparation of building components, joists, etc., can solve the problem of uneven spacing between prefabricated steel cage stirrups, and achieve free formwork spacing. Accurate, strong integrity and consistent stirrup spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below with reference to the drawings and specific implementation methods.

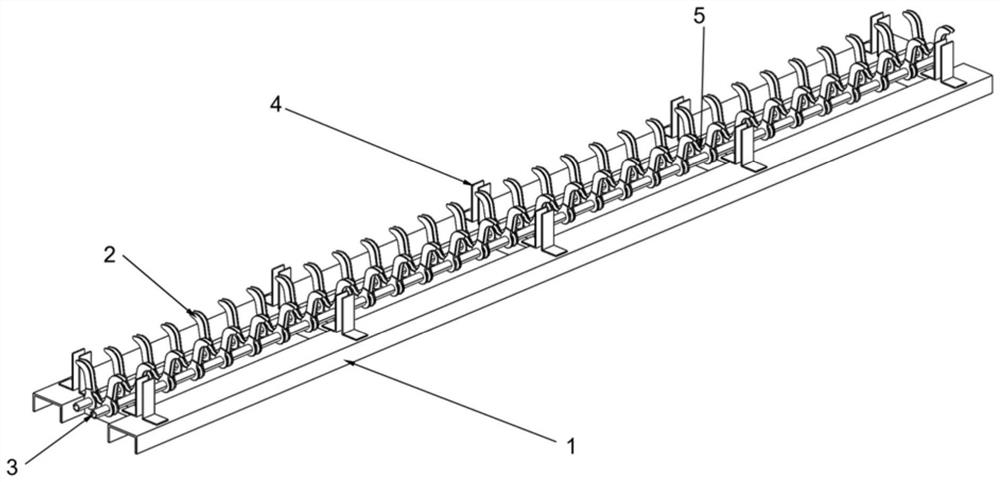

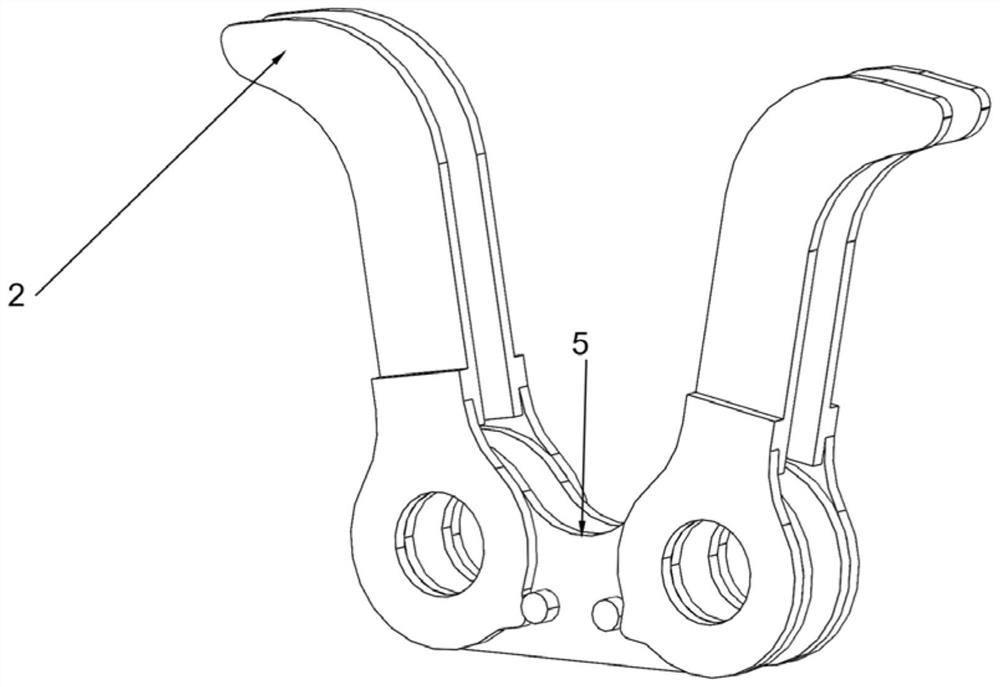

[0036] see Figure 1 to Figure 7 , an auxiliary tooling for the production of an integrated beam member prefabricated steel bar skeleton and formwork connection according to the present invention, comprising a base 1, an ear plate 2, an ear plate main shaft 3, and a formwork limiting slot 4, see figure 1 .

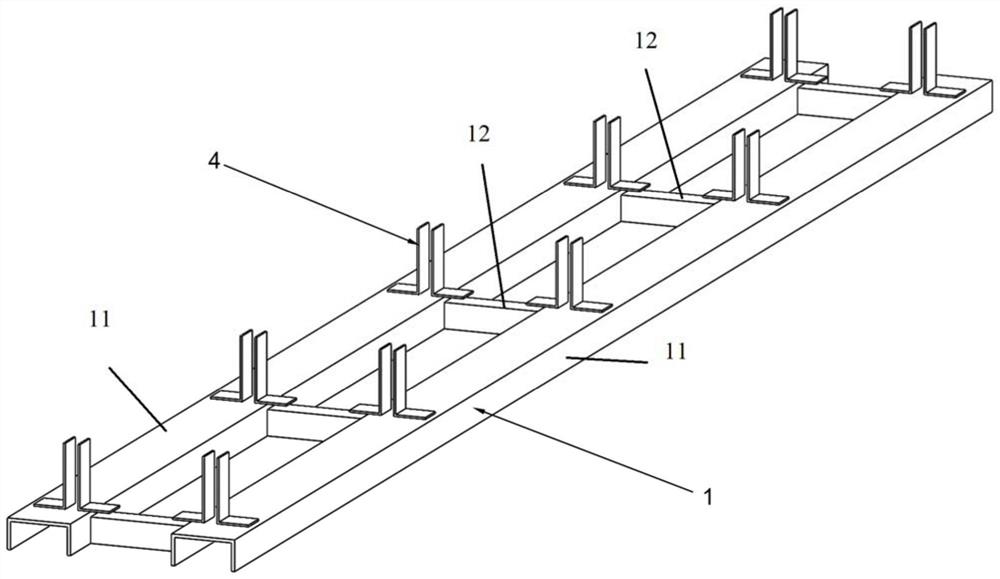

[0037] Such as figure 2 As shown, the base 1 is formed by arranging two channel steels 11 side by side, and the channel steels 11 are welded together by multiple groups of square tubes 12 . Multiple sets of lug plates 2 arranged at intervals are sequentially sleeved on two lug plate main shafts 3, and multiple sets of lug plates 2 sleeved on each lug plate main shaft 3 form a row of lug plates, and the two rows of lug plates are arranged in a splayed shape. The lug main shaft 3 is longitudinally welded on the squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com