Distributed casing corrosion real-time monitoring system

A real-time monitoring system, distributed technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, analysis materials, etc., can solve the problems of large limitations, long cycle, low efficiency, etc., to achieve monitoring and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

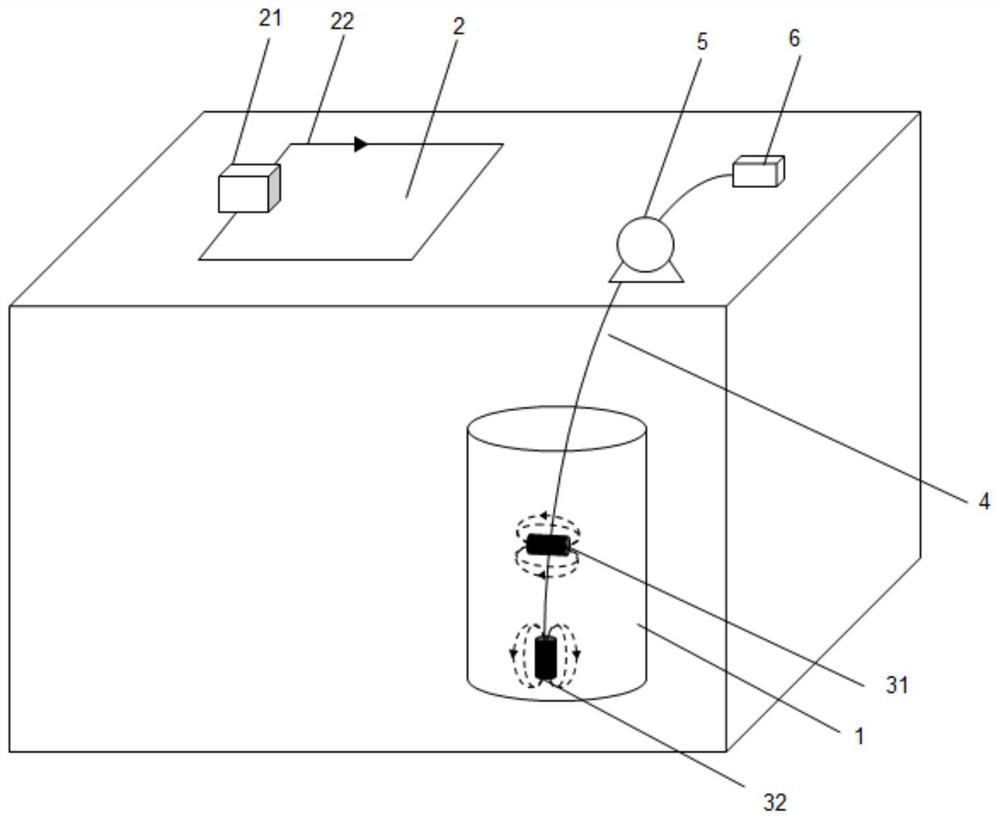

[0036] see Figure 1 ~ Figure 3 As shown, a distributed casing corrosion real-time monitoring system includes:

[0037] wellbore casing 1 located below the surface;

[0038] The launch loop device 2 installed on the ground above the wellbore casing 1 is used as a launch source to launch a magnetic field;

[0039] The probe 3 installed on the steel cable 4 is used to receive the secondary magnetic field response signal generated by the wellbore casing;

[0040] The steel cable 4 is used for fixing the probe 3;

[0041] Winch 5 is used for lowering and reclaiming steel cable 4;

[0042] The data transmission line installed on the steel cable 4 is used to transmit the secondary magnetic field response signal received by the probe 3;

[0043] The receiver 6 installed on the ground and near the transmitting loop device 2 is used to process and summarize the secondary magnetic field response signal received by the data transmission line into a secondary electromagnetic response ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com