Matrix technology-based water-cooled wall thinning on-line monitoring method

A water-cooled wall and water-cooled wall tube technology, applied in the field of non-destructive testing, can solve the problems of manual testing, time-consuming and laborious, and achieve the effect of accurate results and effective positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

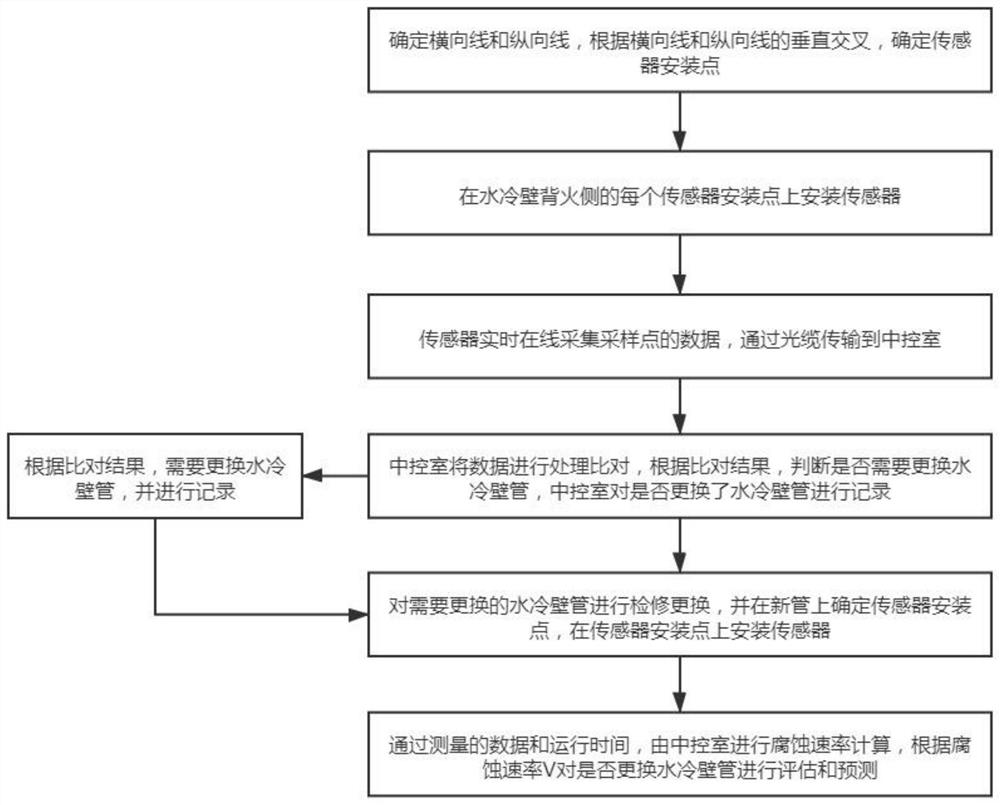

[0025] Embodiment 1 of the present invention: a method of monitoring water-free wall thinning based on matrix technology, including the following steps:

[0026] S1, determine the transverse wire and longitudinal line on the back of the water-cooled wall back, determine the number of transverse lines according to the number of layers of the burner, is equidistant from the transverse wire, the plurality of transverse lines, and multiple vertical lines vertical. Cross, get a plurality of intersections, the intersection is the sensor mounting point, labeled the sensor mounting point of the sensor on the water-cooled wall back side, and records the data information of the sensor mounting point in the central control chamber;

[0027] S2, install the sensor on each sensor mount point on the back fire on the water-cooled wall, the sensor mounting point is the sampling point, the sensor passes the insulation layer, the receiving wire, and the plurality of wires are collected to the micro...

Embodiment 2

[0031] Embodiment 2 of the present invention: a method based on matrix technology online monitoring of water-free wall thinning, including the following steps:

[0032] S1, determine the transverse wire and longitudinal line on the back of the water-cooled wall back, determine the number of transverse lines according to the number of layers of the burner, is equidistant from the transverse wire, the plurality of transverse lines, and multiple vertical lines vertical. Cross, get a plurality of intersections, the intersection is the sensor mounting point, labeled the sensor mounting point of the sensor on the water-cooled wall back side, and records the data information of the sensor mounting point in the central control chamber;

[0033] S2, install the sensor on each sensor mount point on the back fire on the water-cooled wall, the sensor mounting point is the sampling point, the sensor passes the insulation layer, the receiving wire, and the plurality of wires are collected to th...

Embodiment 3

[0038] Embodiment 3 of the present invention: a method of monitoring water-free wall thinning based on matrix technology, including the following steps:

[0039]S1, determine the transverse wire and longitudinal line on the back of the water-cooled wall back, determine the number of transverse lines according to the number of layers of the burner, is equidistant from the transverse wire, the plurality of transverse lines, and multiple vertical lines vertical. Cross, get a plurality of intersections, the intersection is the sensor mounting point, labeled the sensor mounting point of the sensor on the water-cooled wall back side, and records the data information of the sensor mounting point in the central control chamber;

[0040] S2, install the sensor on each sensor mount point on the back fire on the water-cooled wall, the sensor mounting point is the sampling point, the sensor passes the insulation layer, the receiving wire, and the plurality of wires are collected to the microp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com