Track steel surface defect segmentation method based on feature pyramid and neural network

A feature pyramid and convolutional neural network technology, applied in the field of machine vision and deep learning, can solve problems such as long time and inability to use real-time detection, achieve the effect of small number of samples, help network learning, and improve network learning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

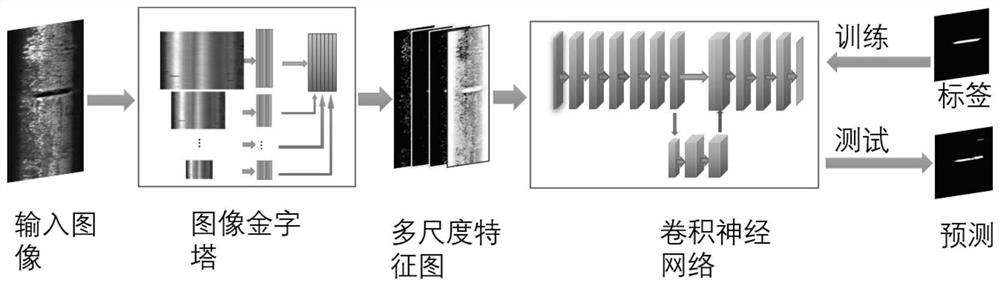

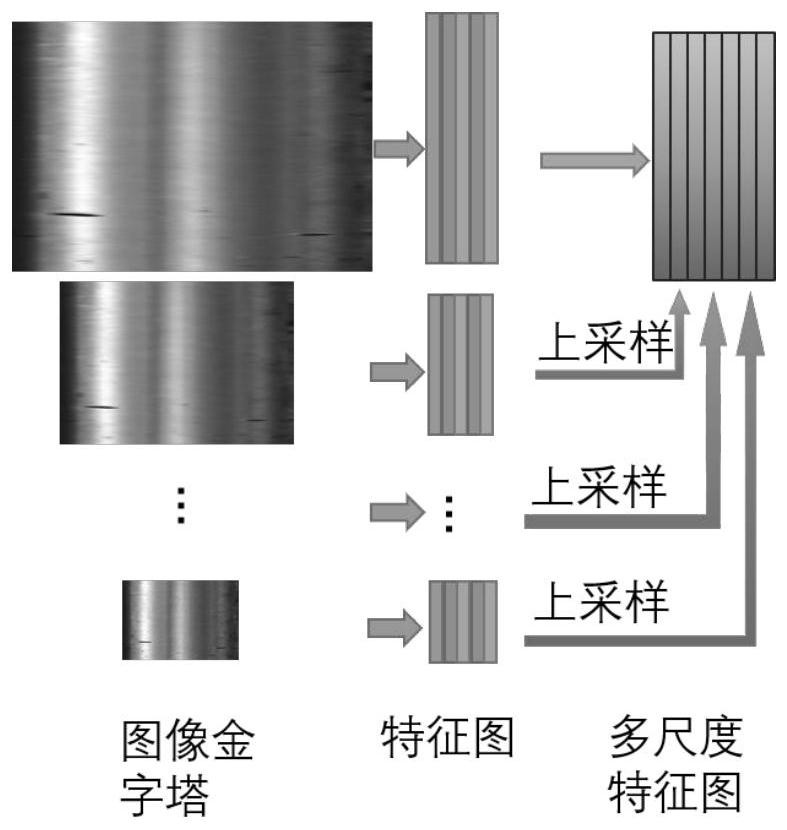

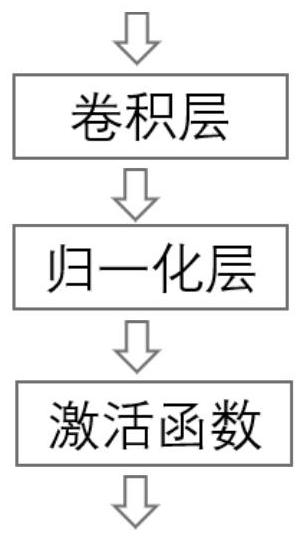

[0083] This embodiment mainly proposes an image segmentation technology combining traditional feature extraction technology and deep learning for the surface of rail steel. First, construct an image pyramid, then extract multi-scale features, and then use multi-scale features as the input of convolutional neural network, train Convolutional neural network. The trained convolutional neural network is able to complete the task of defect segmentation on rail steel surfaces.

[0084] figure 1 It is a flow chart of a method for segmenting surface defects of rail steel based on feature pyramid and convolutional neural network disclosed in this embodiment, and will be described through specific embodiments below. A method for surface defect segmentation of rail steel based on feature pyramid and convolutional neural network, the specific steps are as follows:

[0085] S1. Taking the surface image of rail steel as the input image I 0 , through the input image I 0 Sequentially perf...

Embodiment 2

[0145] In this embodiment, the data set contains a total of 67 samples, 40% or 27 samples are randomly selected as the training set, and the remaining 40 samples are used as the test set, and each sample contains one or more defects. In the examples, three methods based on convolutional neural networks are compared with the method proposed by the present invention, all methods use the same training set and test set. The three methods used for comparison are Unet++, Deeplab, and Segnet respectively, and the method proposed by the present invention is denoted as PFCNN. The measurement results of different methods are shown in Table 1 below:

[0146] Table 1. Evaluation index table of different methods

[0147]

[0148] Where PR, RC, FM are defined as follows:

[0149] PR=TP / (TP+FP); RC=TP / (TP+FN); FM=2×PR×RC / (PR+RC)

[0150] Among them, TP represents the number of defective pixels predicted to be defective, FP represents the number of non-defective pixels predicted to be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com