Inner and outer diameter measuring device for bearing quality detection

A measuring device and a technology of inner and outer diameters, which are applied in the field of bearings, can solve the problems of high-precision fit, low work efficiency, and easy errors, and achieve the effect of high automation and improved measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

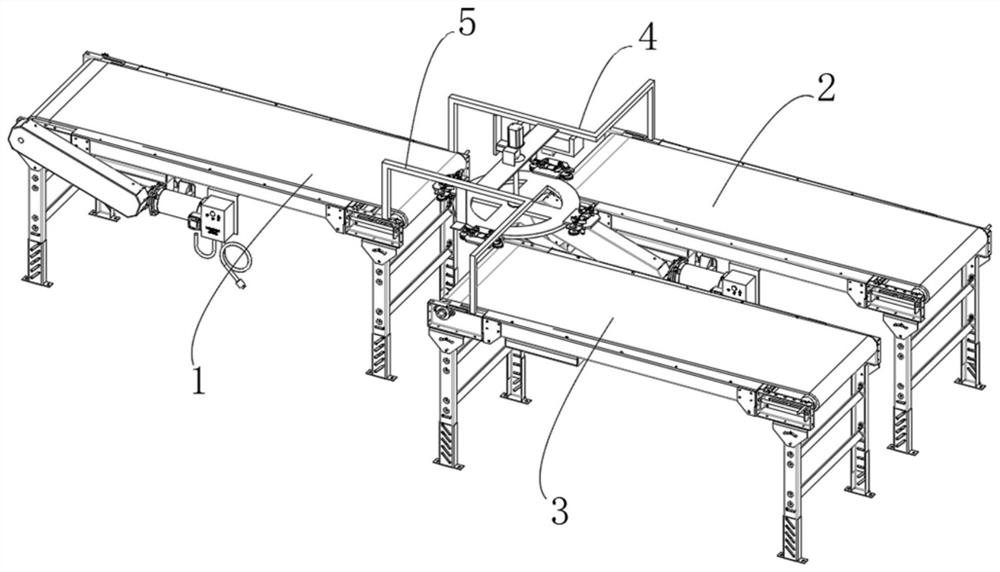

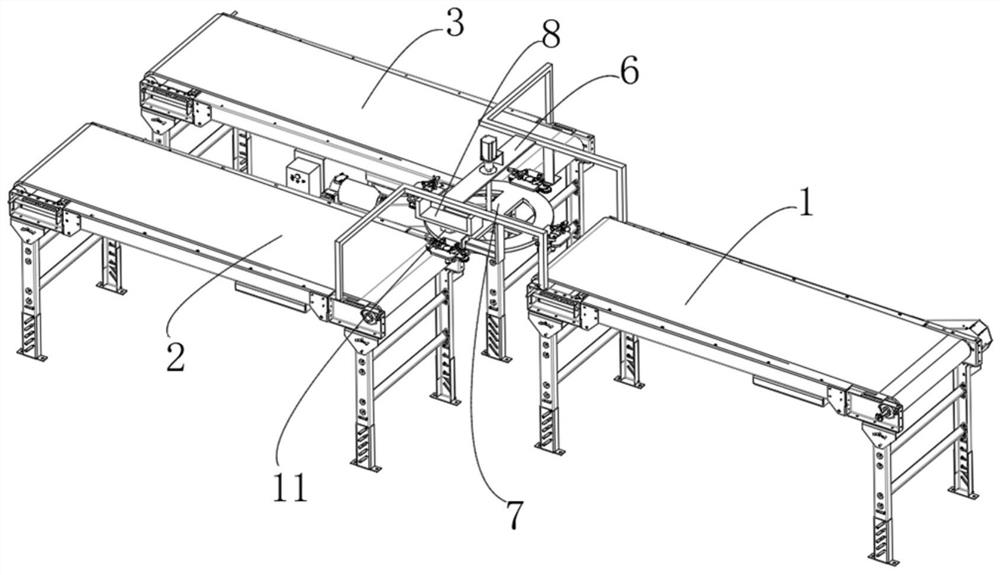

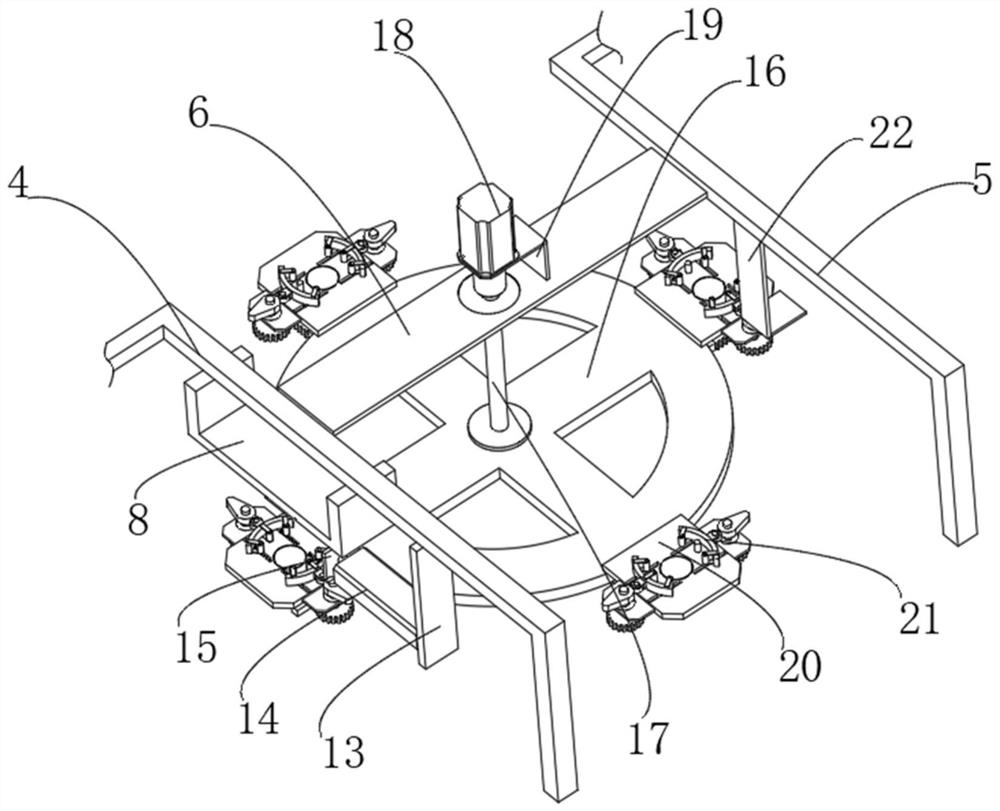

[0028] Such as Figure 1-Figure 3 and Figure 9 As shown in the figure, a bearing quality inspection device for measuring inner and outer diameters includes a first conveyor belt 1, a second conveyor belt 2 and a third conveyor belt 3, the second conveyor belt 2 and the third conveyor belt 3 are symmetrically distributed, and the first conveyor belt 1 is located near the input end of the second conveyor belt 2, a first bracket 4 is fixed between the tops of the first conveyor belt 1 and the second conveyor belt 2, and a second bracket 5 is fixed between the tops of the first conveyor belt 1 and the third conveyor belt 3, A mounting plate 6 is fixed between the tops of the first support 4 and the second support 5; the disc feeding mechanism 7, which is used to classify qualified and unqualified bearings, is fixed on the mounting plate 6, the first The bottom of the bracket 4 is fixed with a U-shaped plate 8, and the bottom of the U-shaped plate 8 is provided with a card slot 9...

Embodiment 2

[0035] Such as Figure 5 and Figure 7 As shown, this embodiment further illustrates Example 1. The stripping member 37 in the illustration includes a bearing seat 38, a threaded cylinder 39, a threaded rod 40 and a rotating member 41. The bearing seat 38 is fixed to the bottom of the material receiving plate 20. And the threaded barrel 39 is rotatably connected to the bearing seat 38, the threaded rod 40 is threadedly installed inside the threaded barrel 39, and the top end of the threaded rod 40 slides through the center of the receiving plate 20, and is fixed with a bracket 42, a rotating part 41 Connected with the threaded barrel 39 in transmission, the designed stripper 37 can be used to raise the bearing by the source power of the second cylinder 35, and complete the linkage of unclamping the bearing and raising the bearing unloading action.

[0036] Among them, such as Figure 7 and Figure 8 As shown, in order to lift the bearing, the rotating member 41 includes a s...

Embodiment 3

[0039] Such as Figure 9 and Figure 10 As shown, this embodiment further describes Example 1. The bottom of the first bracket 4 in the illustration is fixed with a U-shaped plate 8, and the bottom of the U-shaped plate 8 is provided with a card slot 9, and a card slot 9 is clamped in the card slot 9. Block 10, the bottom of the clamping block 10 is fixedly equipped with an internal and external diameter online measuring instrument 11, and both sides of the internal and external diameter online measuring instrument 11 are provided with a fixing mechanism 12. The fixing mechanism 12 includes a right-angle plate 47 and a limit block 48, and the right-angle plate 47 is fixed. At the bottom of the U-shaped plate 8, the limit block 48 is fixed on the top outside of the on-line measuring instrument 11 for inner and outer diameters, and the bolt rod 49 is threaded on the right-angle plate 47, and the top of the bolt rod 49 is fixed with a briquetting block 50, and the briquetting blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com