Patents

Literature

40results about How to "Suitable for online measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

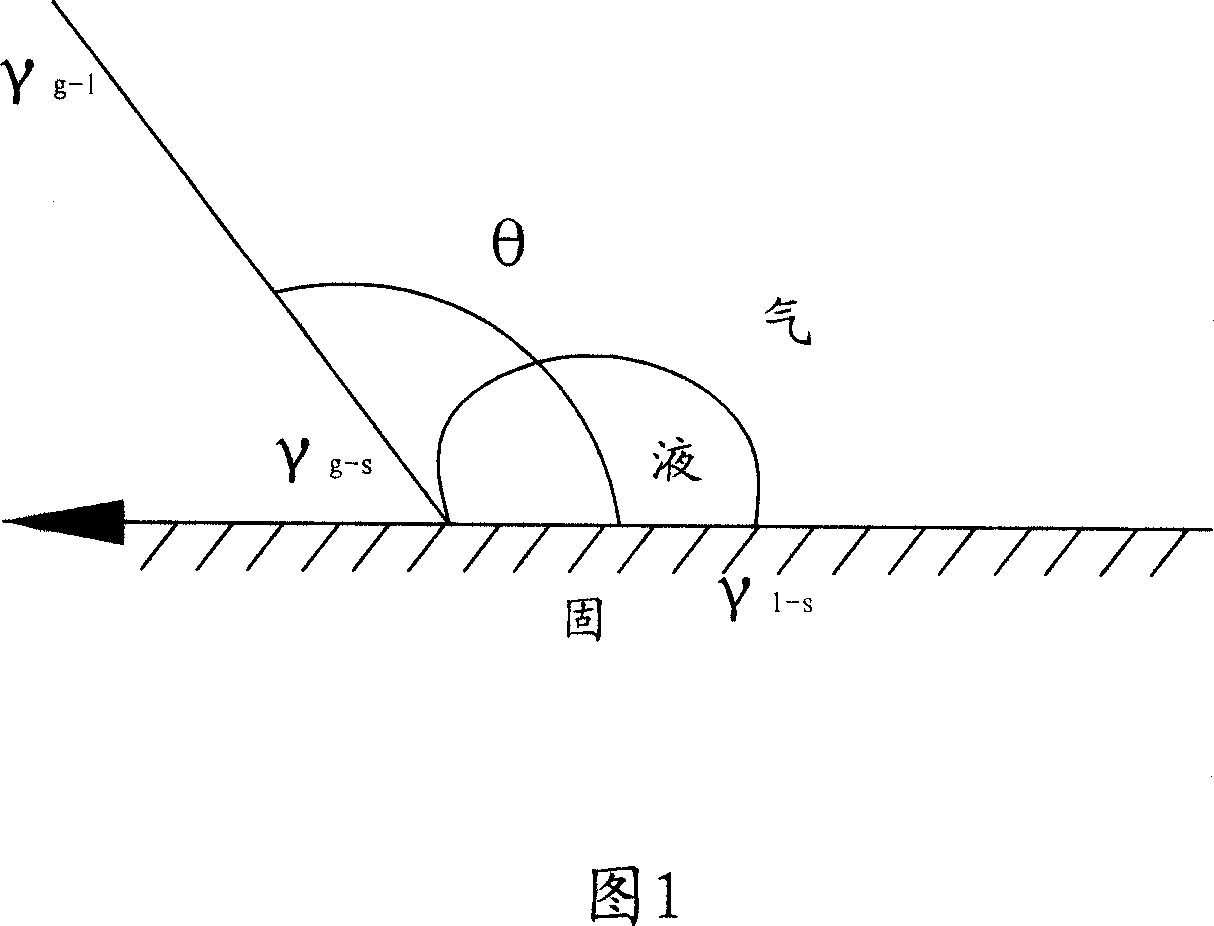

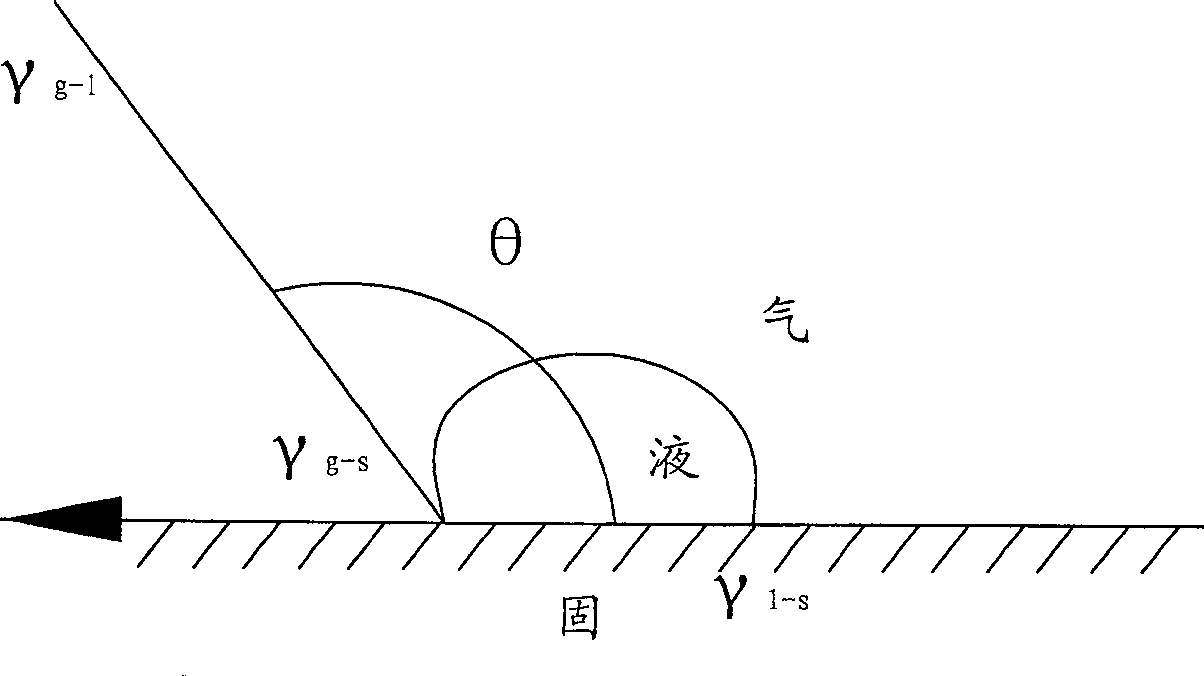

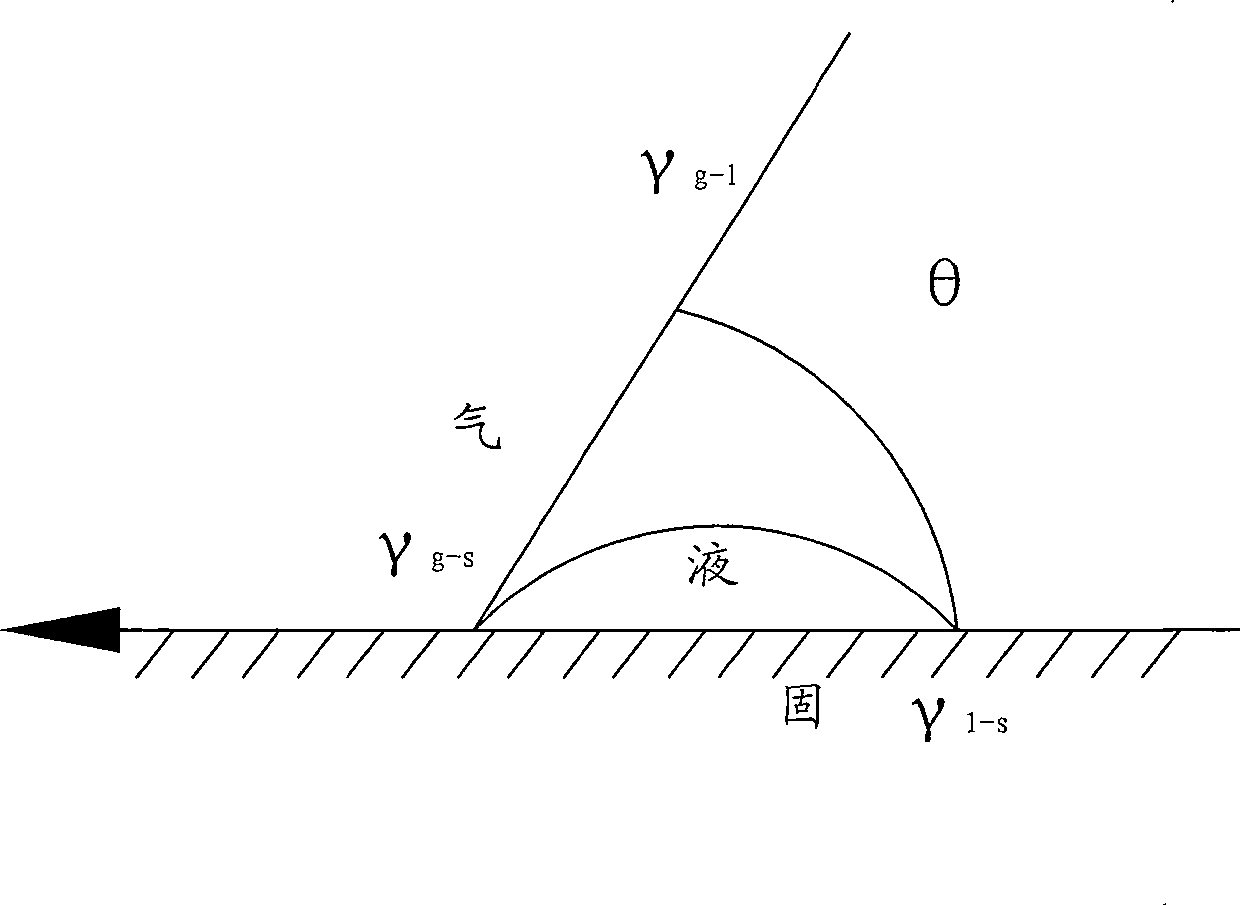

Online measuring method of self clean glass contact angle

ActiveCN101033951AImprove recognitionShorten the timeUsing optical meansMaterial testing goodsEngineeringCoating

This invention provides an online measurement method for self-cleaning glass contact angle. By using the Actual Conditions closed to the self-cleaning glass coating, the hanging drop test method and thelta / 2 Methods, it can measure the self-cleaning glass and its contact angle of related film rapidly and accurately, also more accurately measure the small contact angle compared to other methods.

Owner:FUYAO GLASS IND GROUP

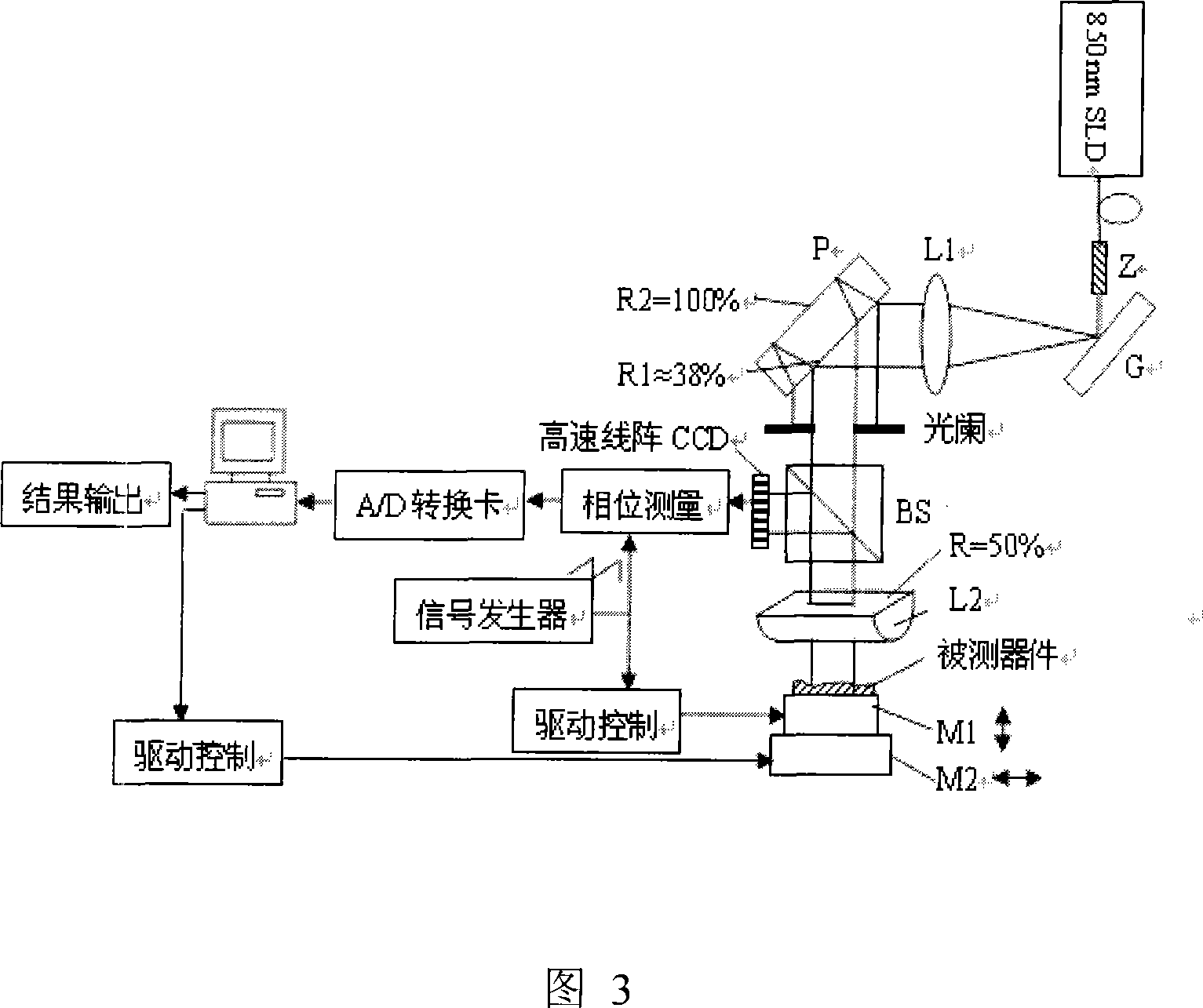

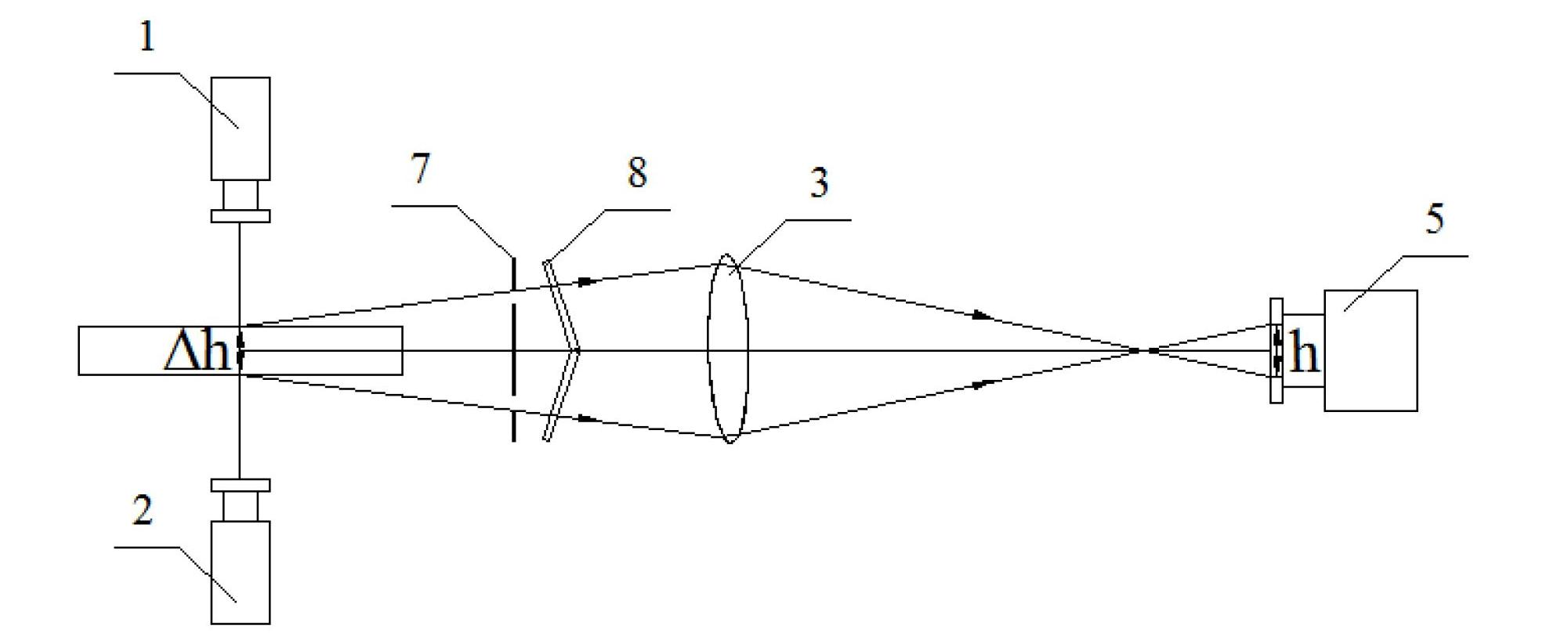

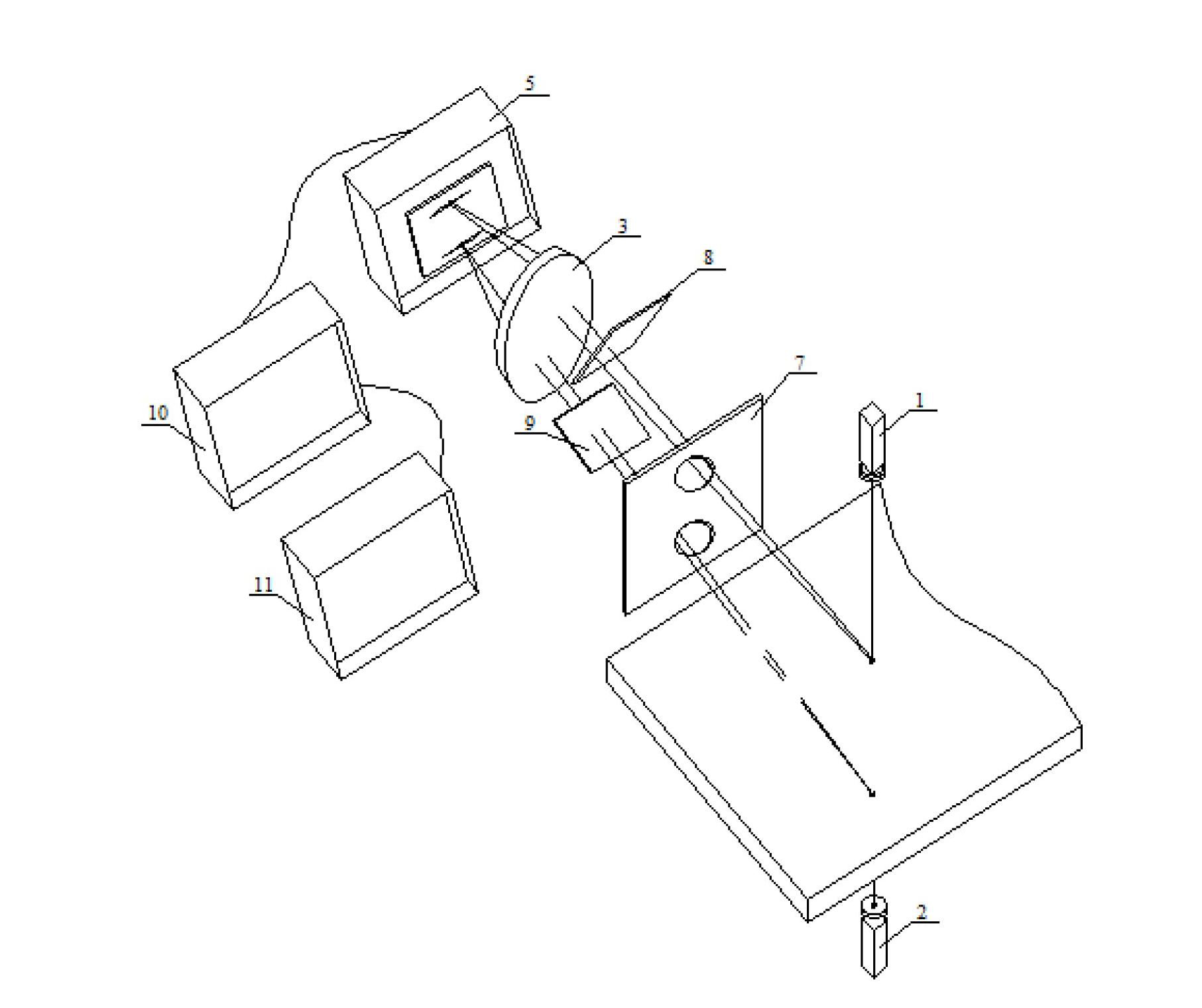

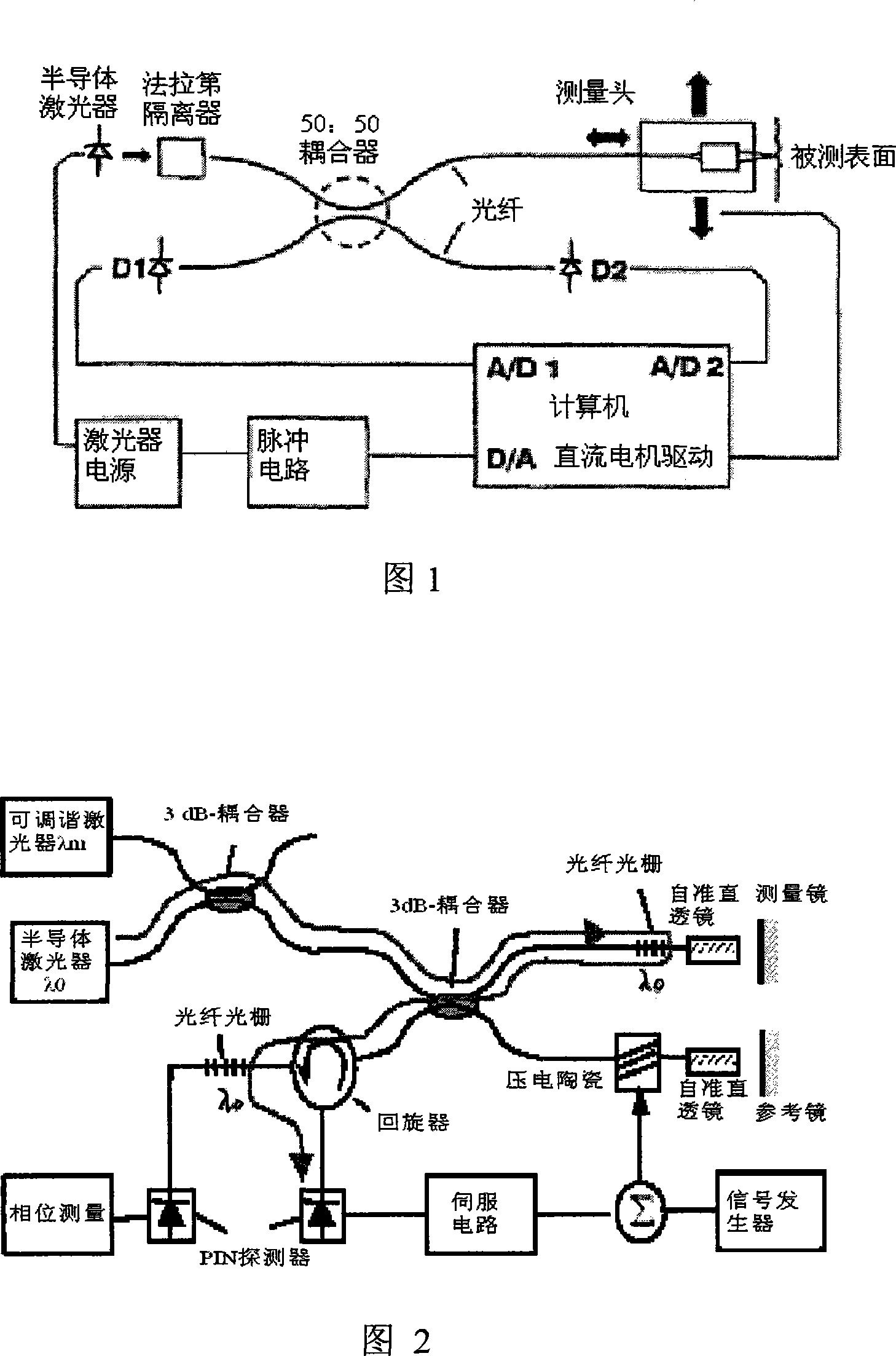

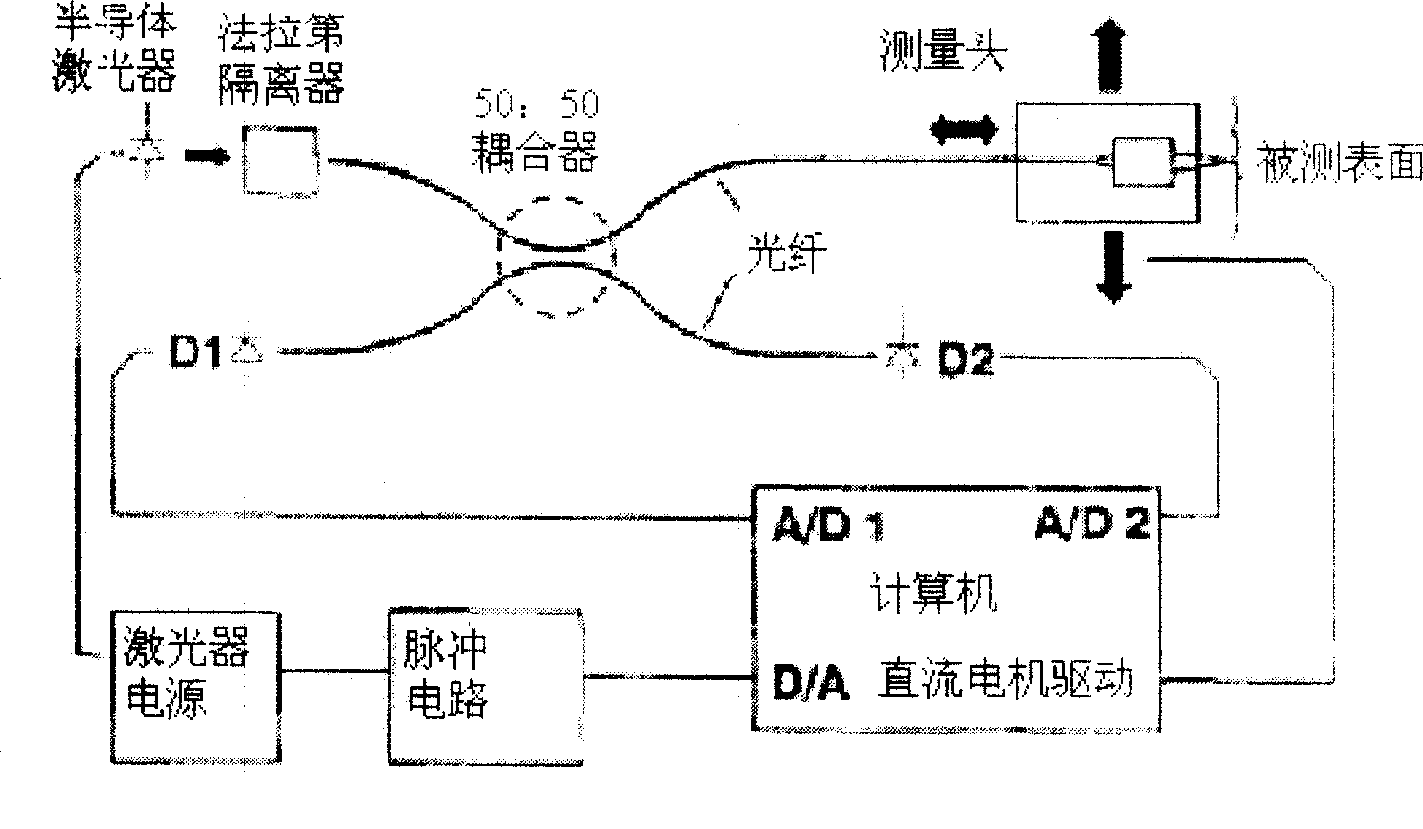

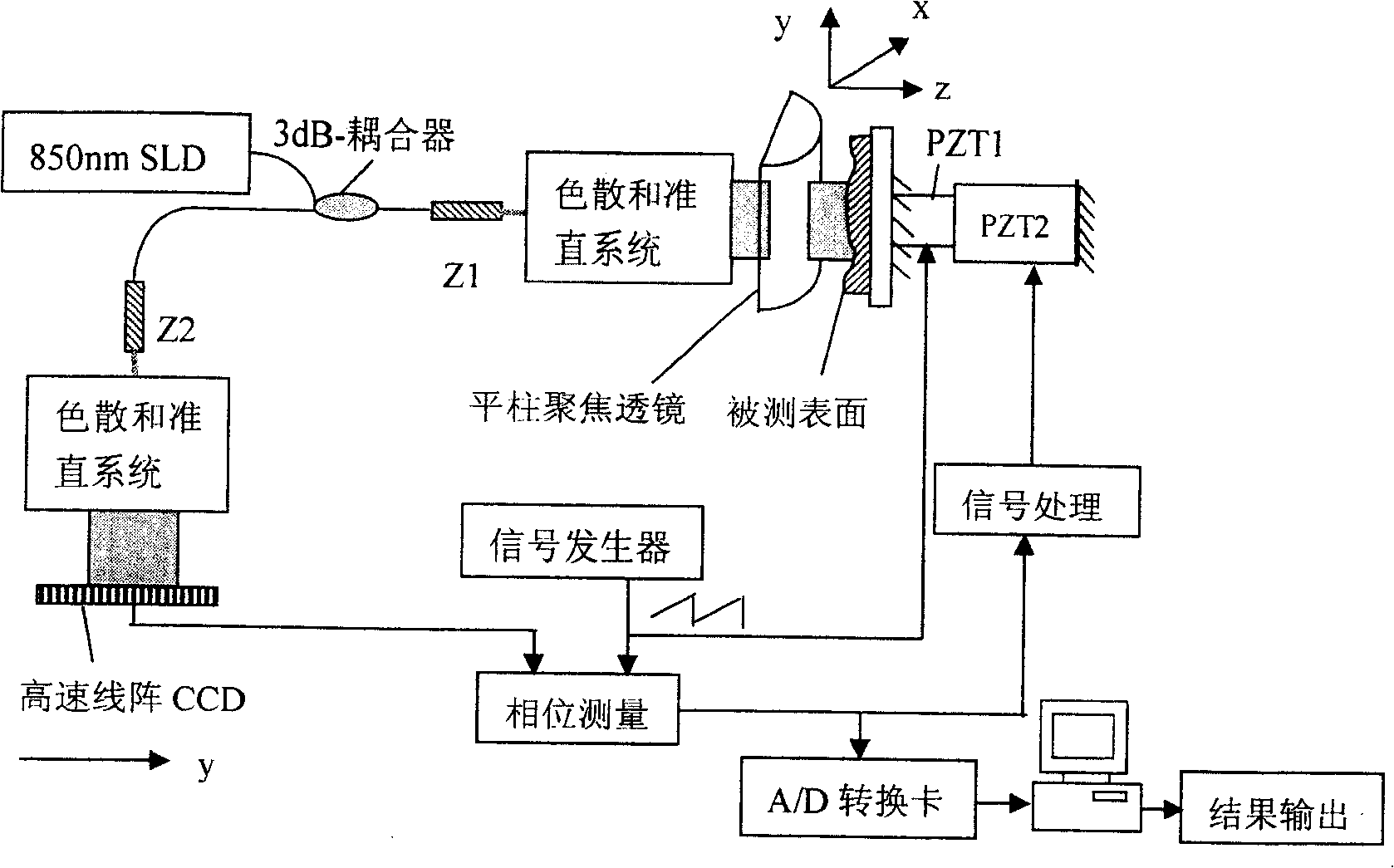

Synthetic wave interference nano surface tri-dimensional on-line measuring system and method

InactiveCN101105391AFast measurementSimple scanning mechanismUsing optical meansOptical elementsNanometre3d measurement

The invention relates to a nano-surface interference 3D online measurement method with composite wave and by light scanning and the system thereof. The range depends on the wavelength of the composite wave, and the system has a common path interference structure. The beam with spectral width of 40 nm is color dispersed into two sectored lights with wavelength continuously and uniformly distributed in space by a grating, the two sectored lights are collimated to two parallel lights with transverse misplacement and partial overlapping, and the overlapped part forms a composite wave. The parallel lights of the composite wave passes through a plano-convex focusing lens with a cylindrical surface coated with a semi-transmitting and reflective film, then one half of the lights are reflected to become reference light and the other half of the lights are focused to become light, and then the light is reflected by different measuring points, interfered with the reference light and detected by an array CCD. If the phase variation of the interference signal of each pixel of CCD is measured, then the longitudinal variation at the measuring point can be obtained. The nano-surface 2D measurement is finished by once location; and the nano-surface 3D measurement is finished by transverse scanning of light. The measurement range is 600-1,000 micron, and the resolution is higher than 5 nm. The invention has the advantages of high measurement speed, and low cost; and is suitable for measurement of nano-surface with boss and deep groove.

Owner:BEIJING JIAOTONG UNIV

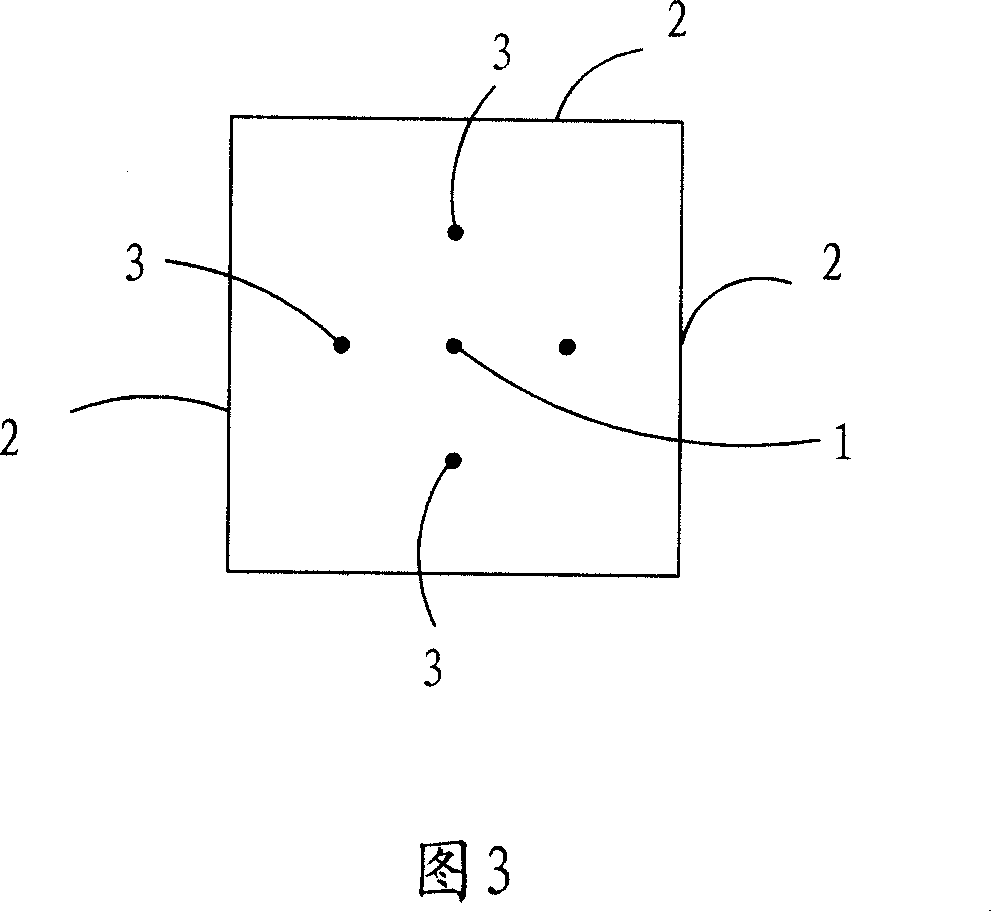

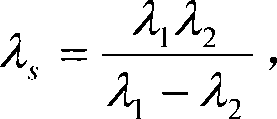

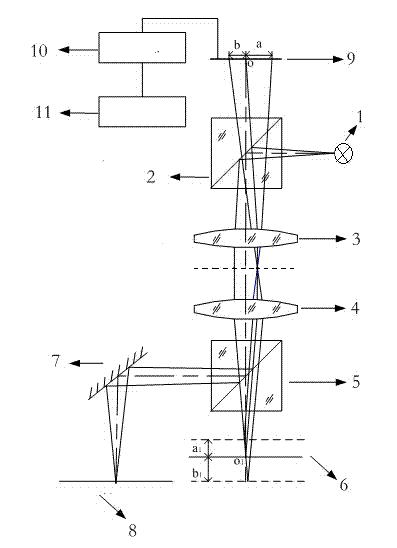

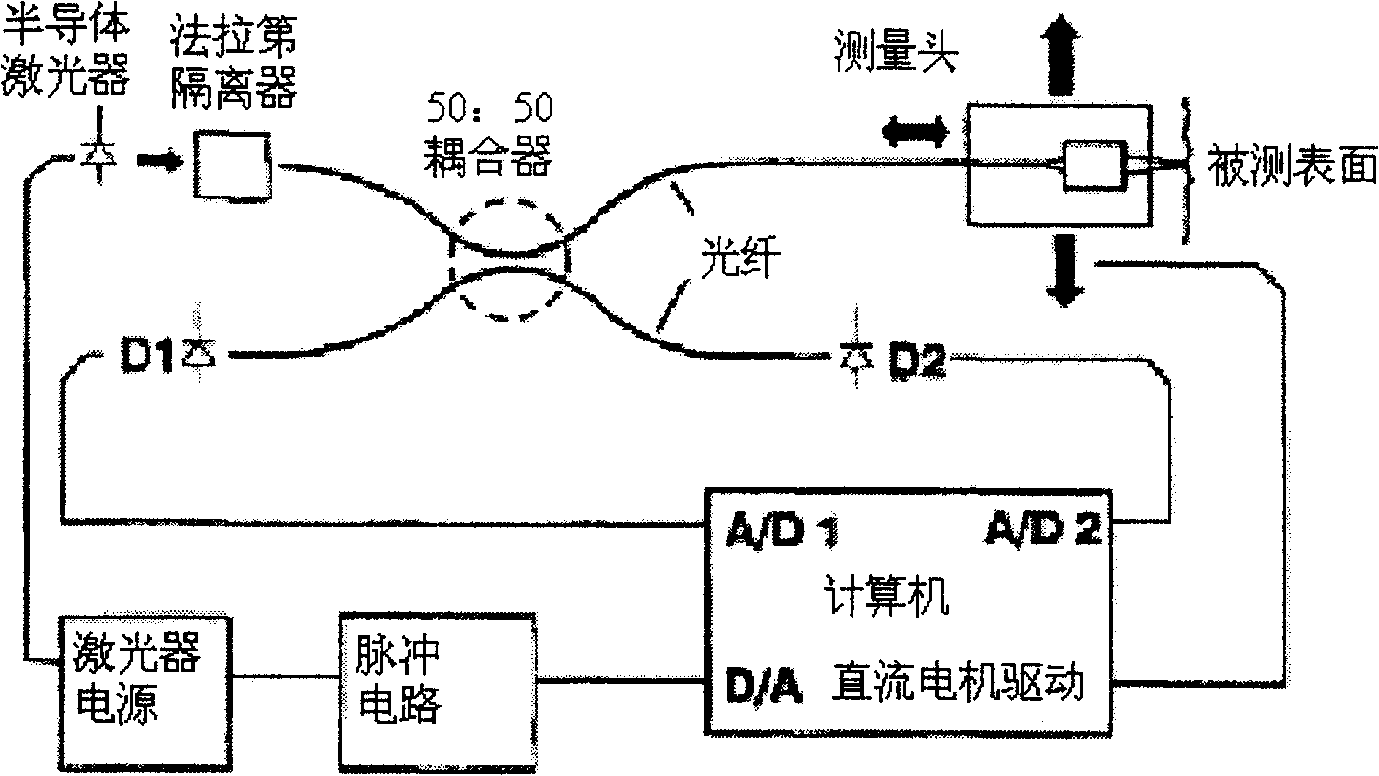

Single-lens laser trigonometry thickness measuring instrument

InactiveCN102679892AImprove real-time performanceGood synchronizationUsing optical meansCamera lensLight spot

The invention belongs to the technical field of geometric size measurement, and discloses a single-lens laser trigonometry thickness measuring instrument. The measuring instrument comprises laser devices, an aperture diaphragm, planar glass, a combined lens, an image detector, an image processor and certain auxiliary fine adjusting devices. When the measuring instrument works, the upper and lower laser devices aligned coaxially emit two beams of collimated rays, the rays are focused to the surface of a measured object by the lens in front of the laser devices, the diffuse reflectance rays on the surface of the measured object pass through the aperture diaphragm and the planar glass and then are gathered to the image detector through the combined imaging lens, image data are transmitted to the image processor for image processing, the actual thickness of the measured object is calculated according to the distance between two light spots, and the measurement thickness is finally displayed. By inheriting the advantages of a laser triangle thickness measuring method, improving the structure of a light path and optimizing the design, the problems that upper and lower independent measuring systems are difficult to synchronize and the precision is difficult to ensure because a double-path laser trigonometry thickness measuring instrument is affected by vibration of the measured object are well solved.

Owner:HUAZHONG UNIV OF SCI & TECH

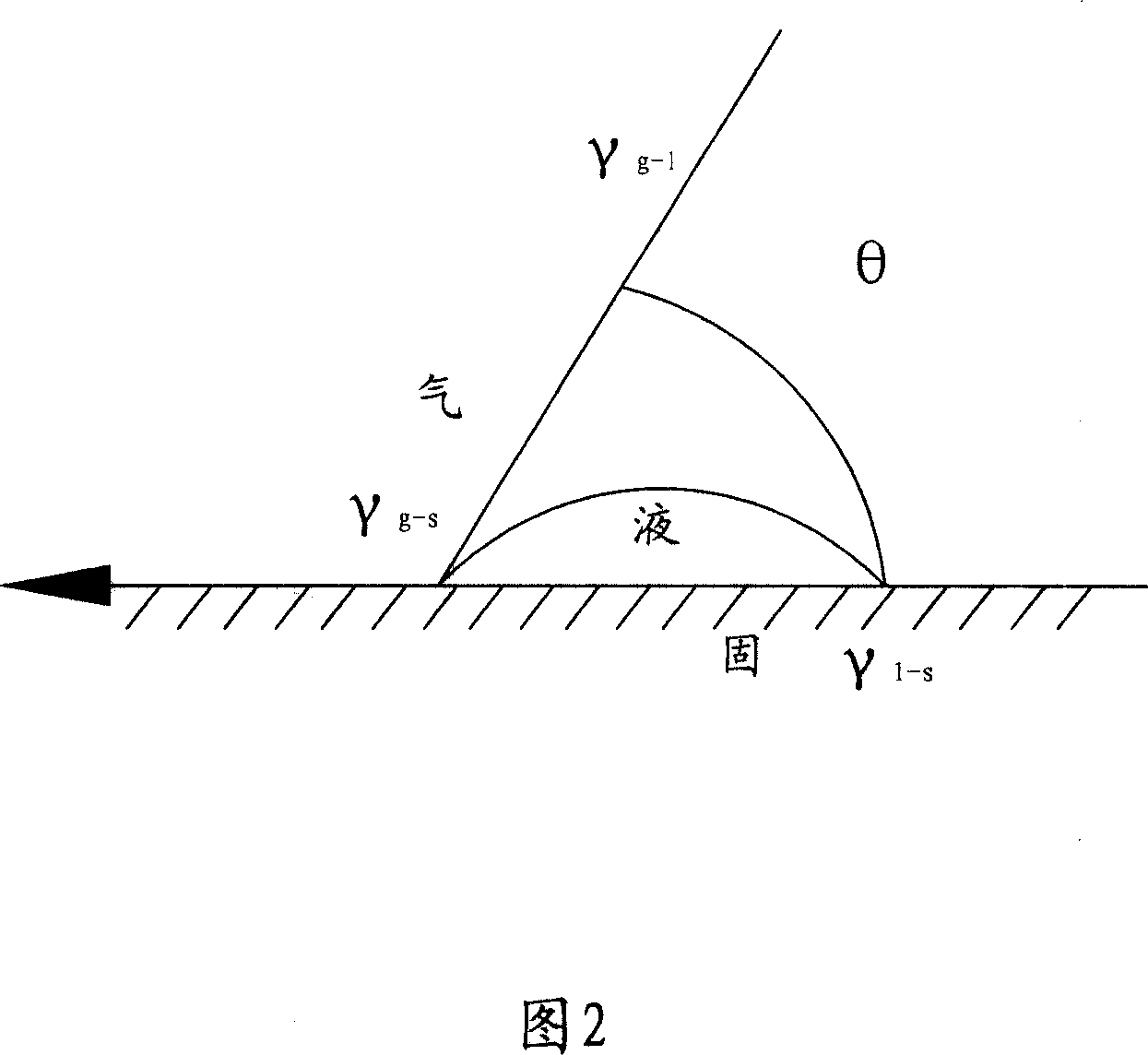

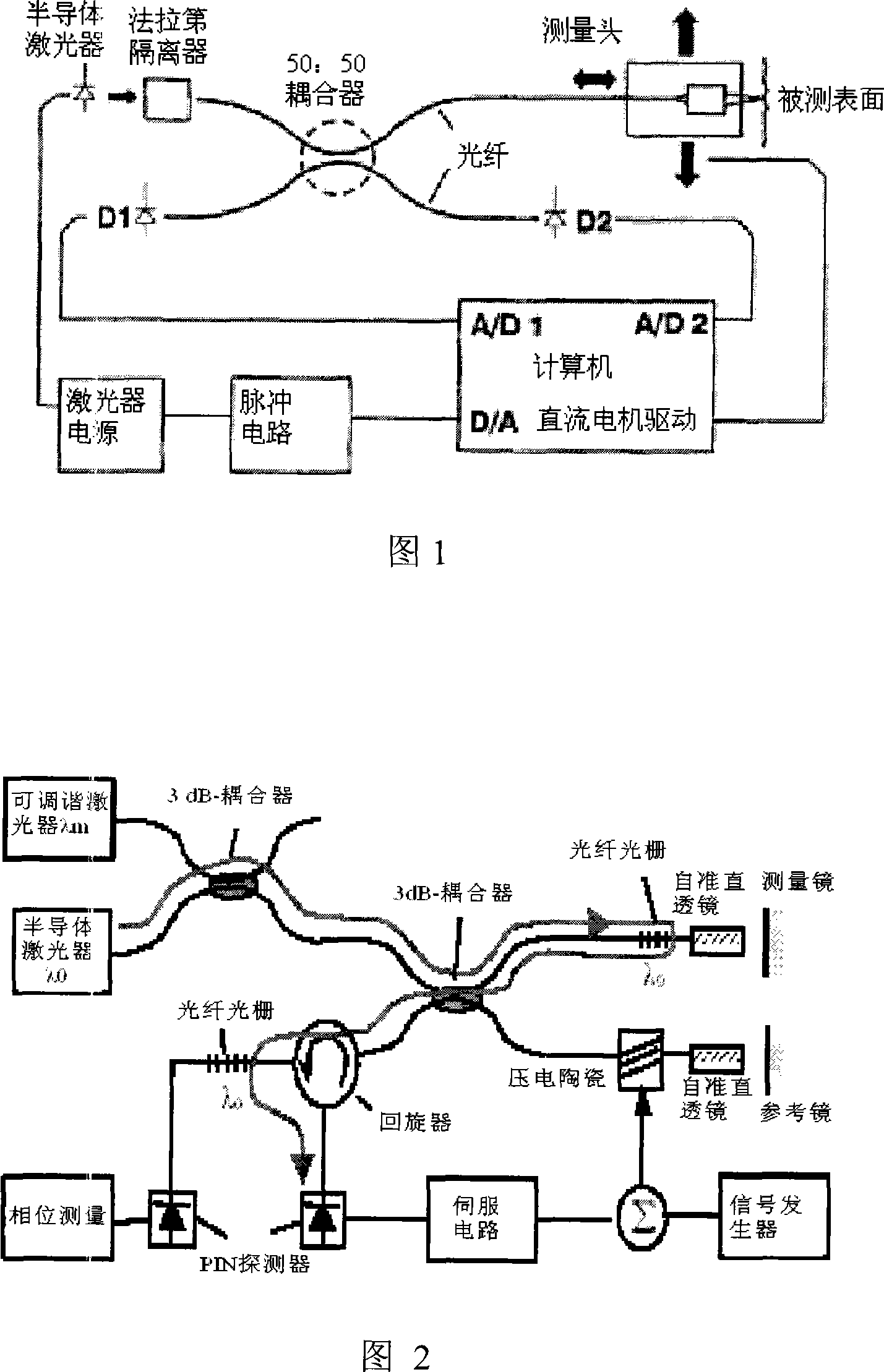

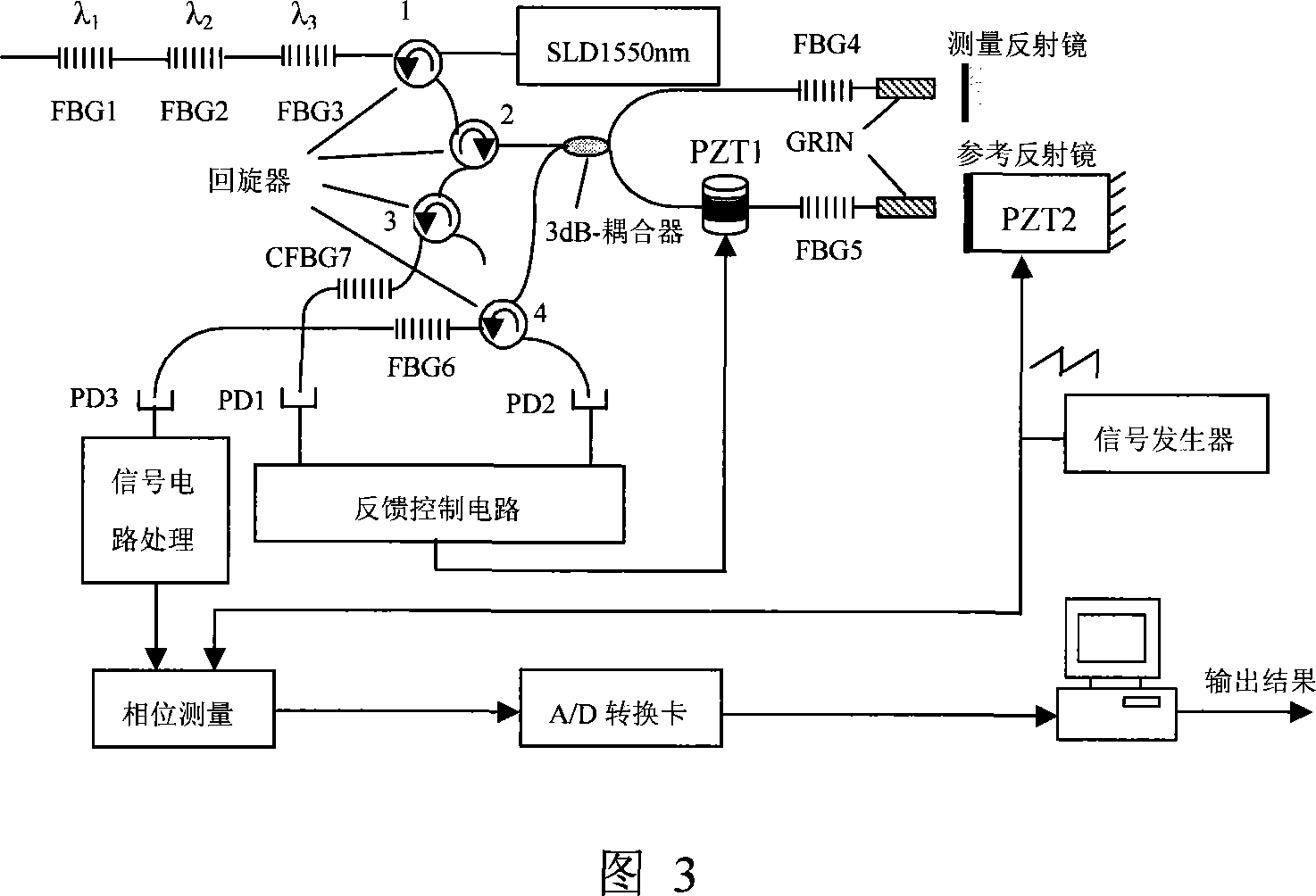

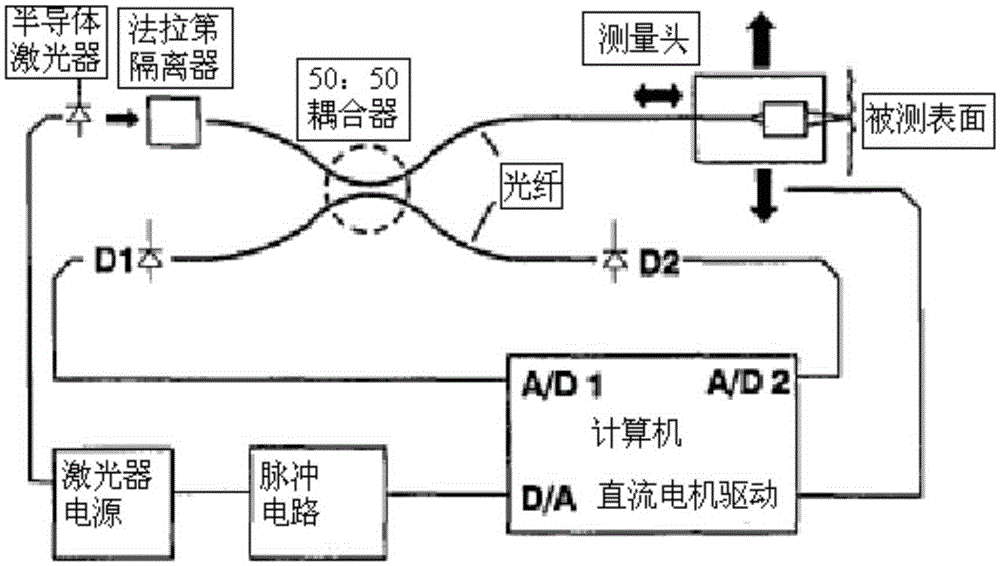

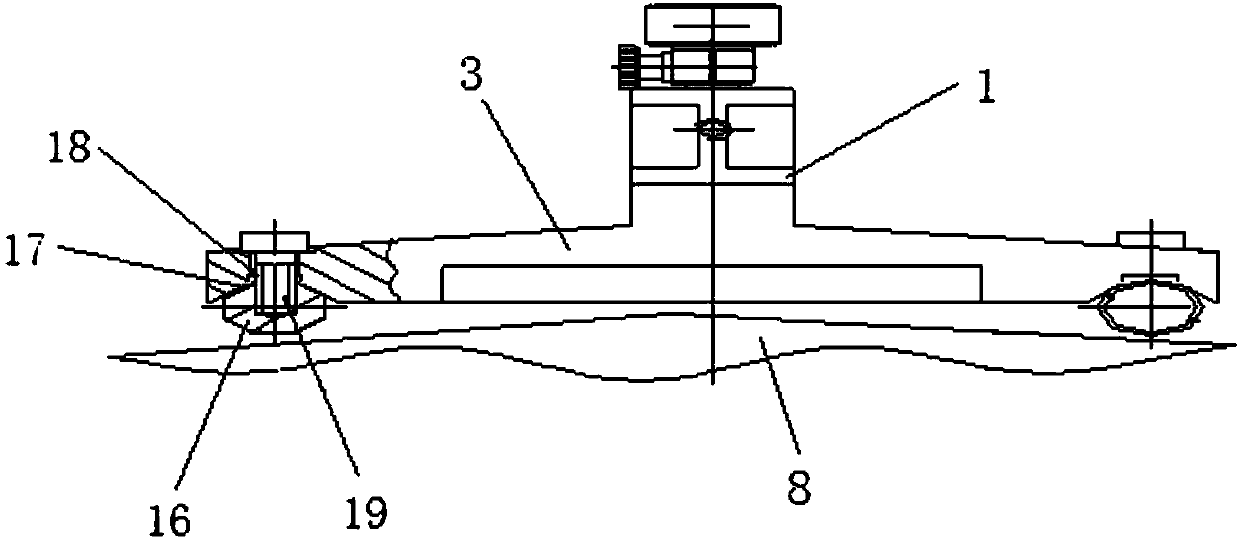

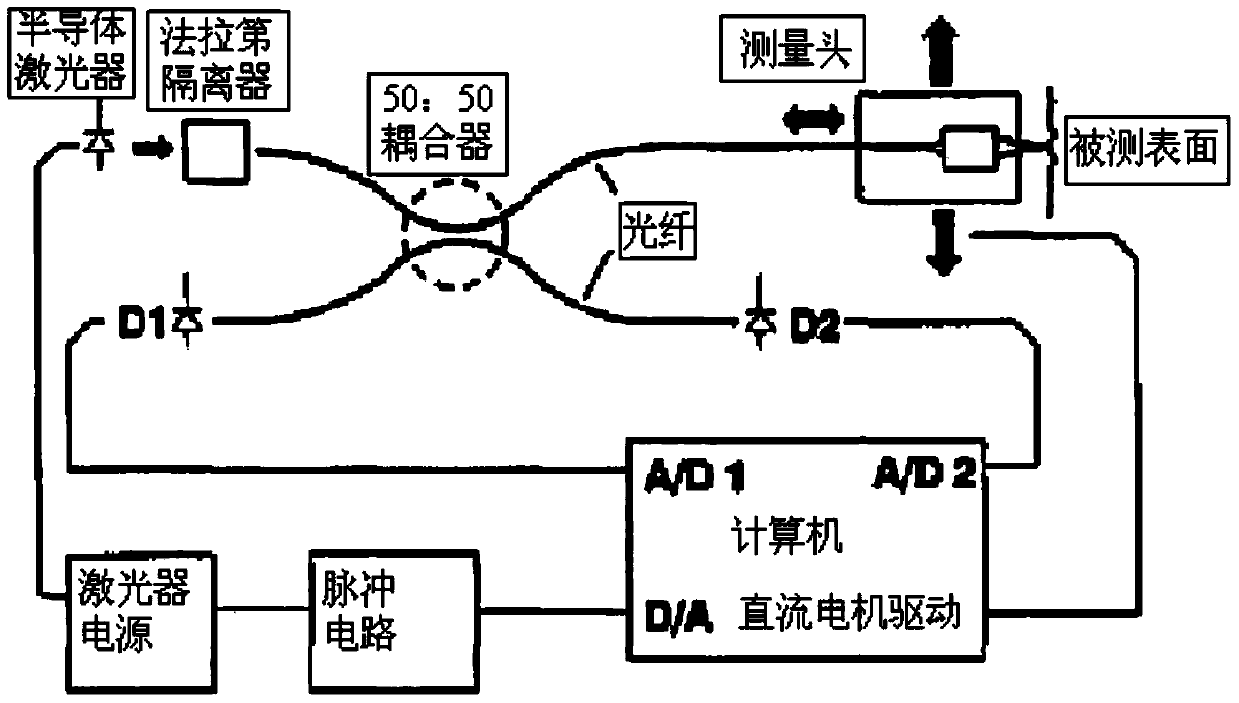

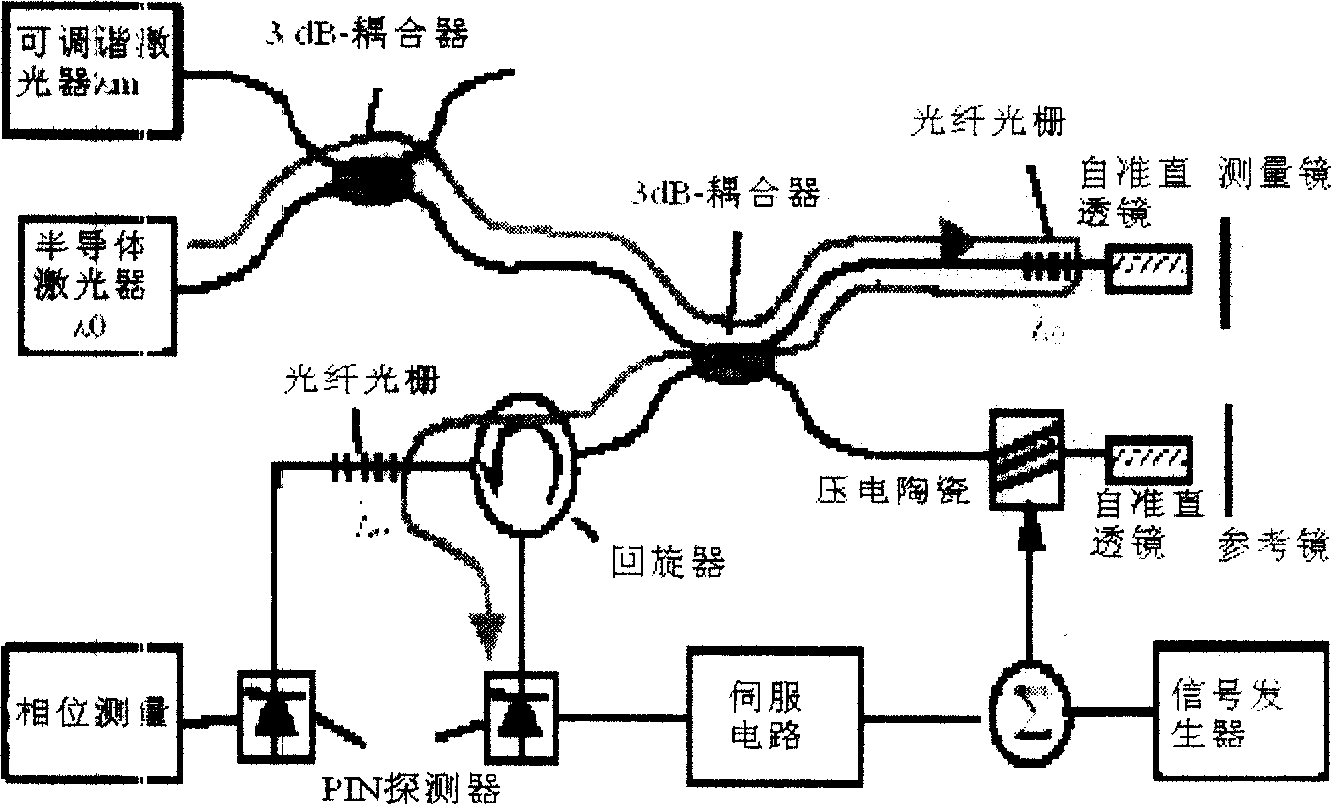

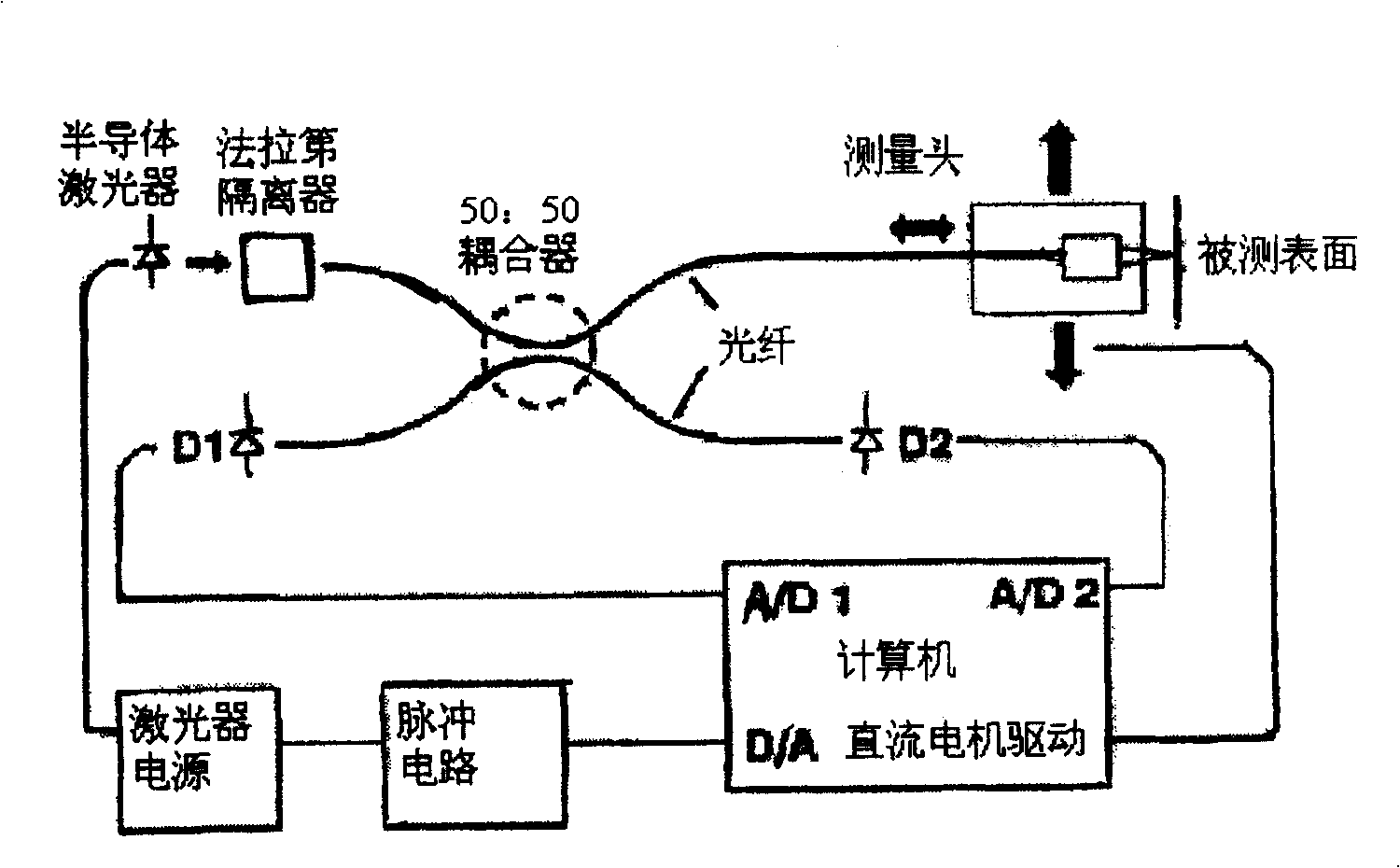

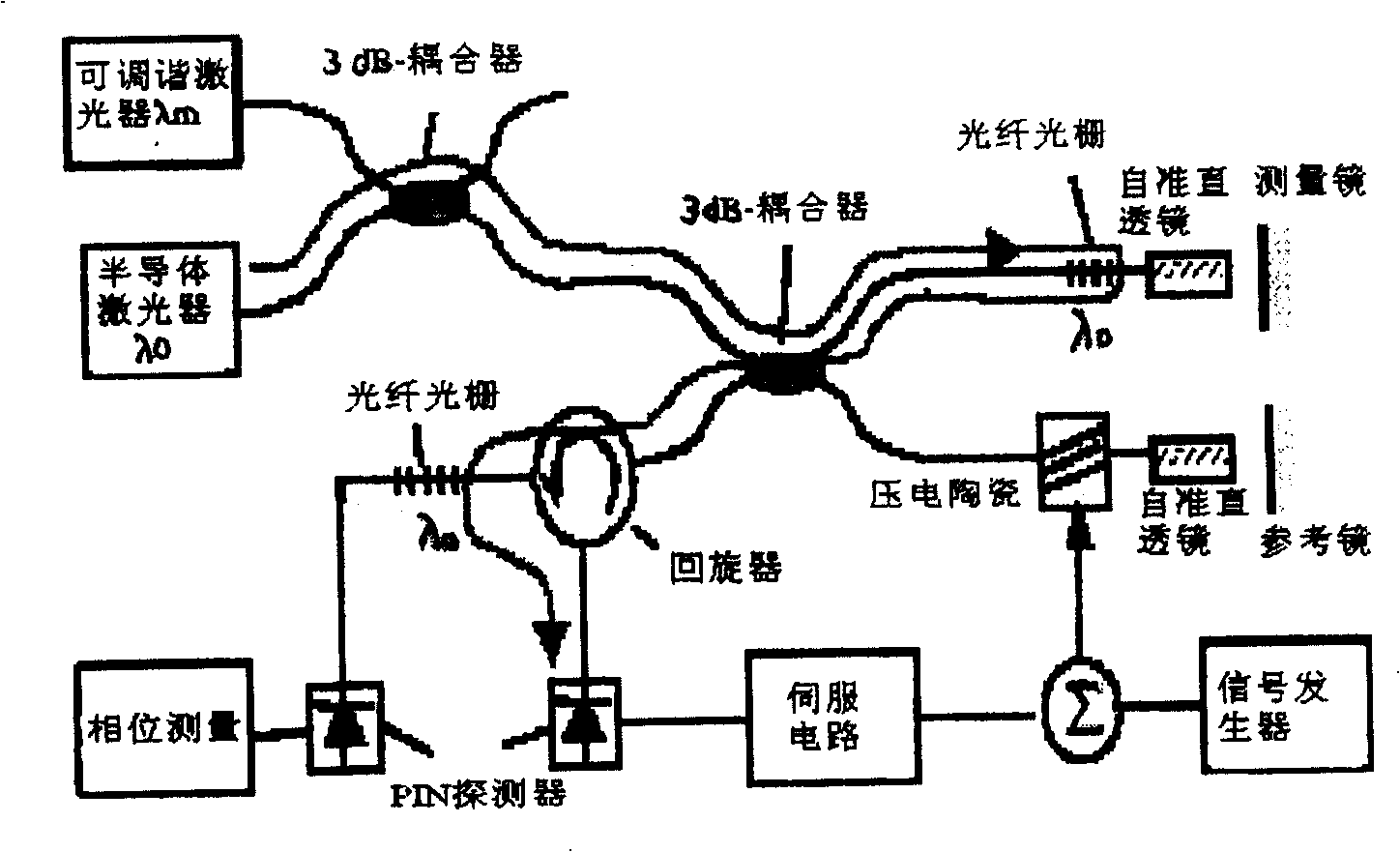

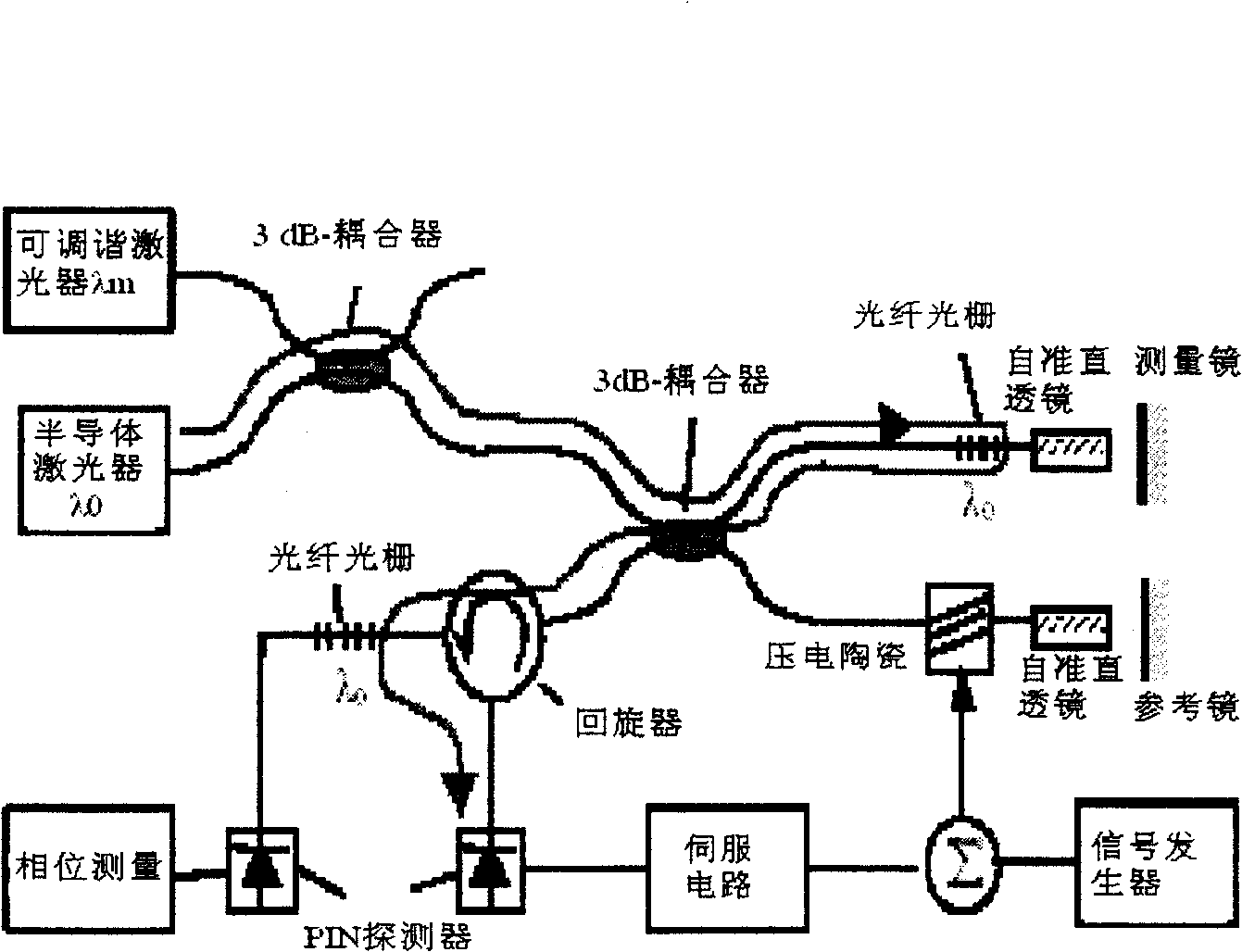

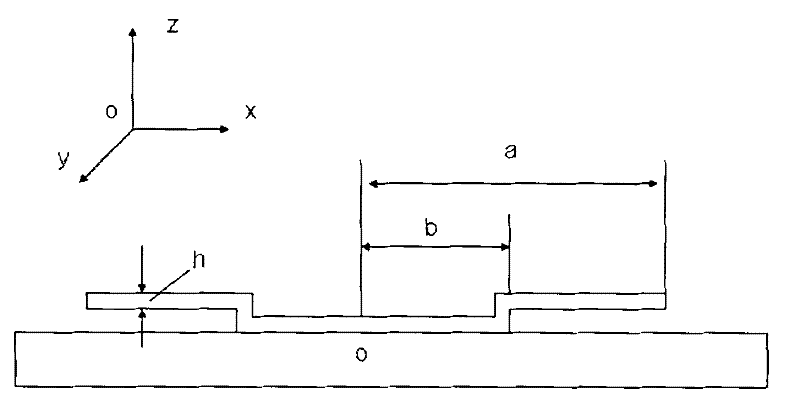

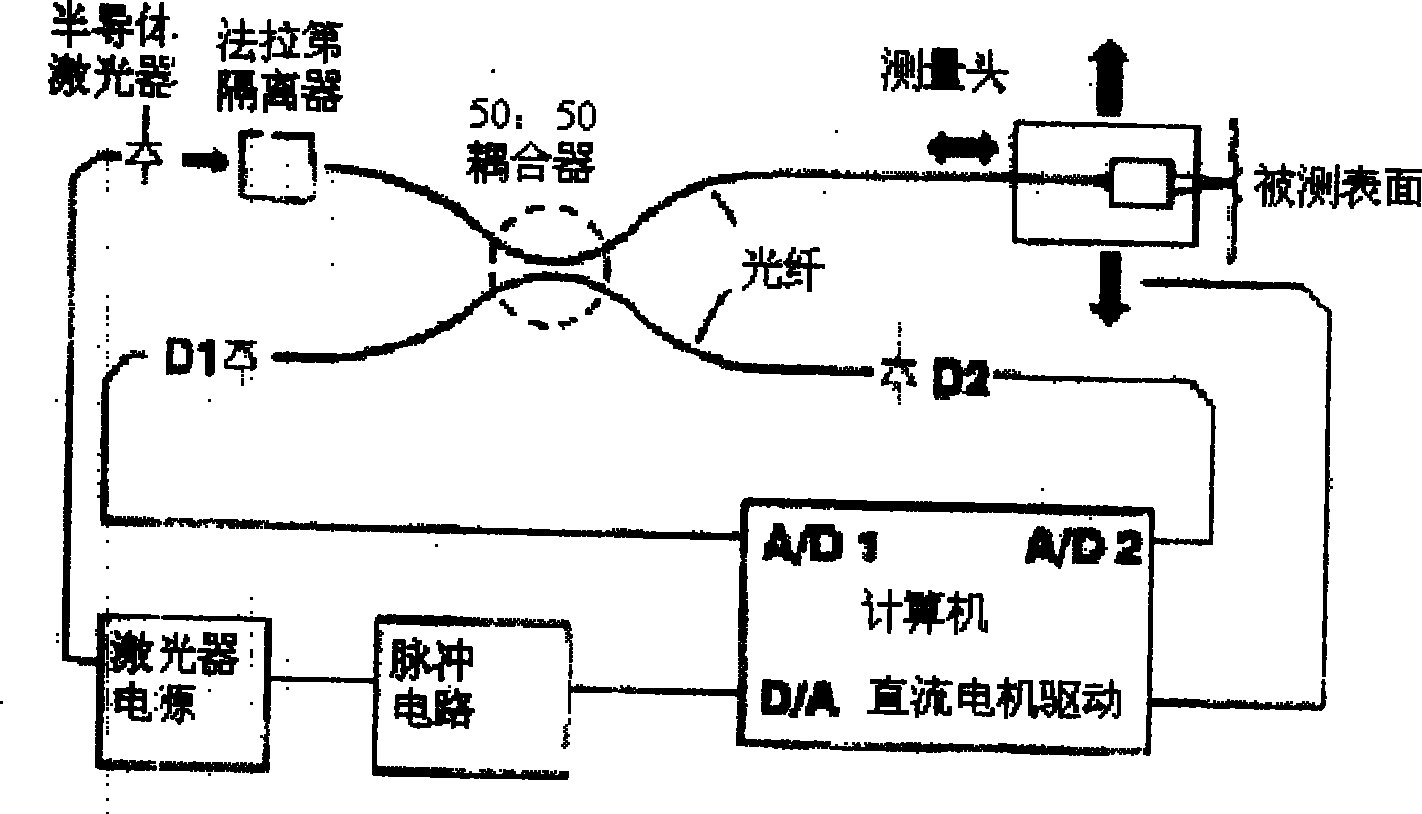

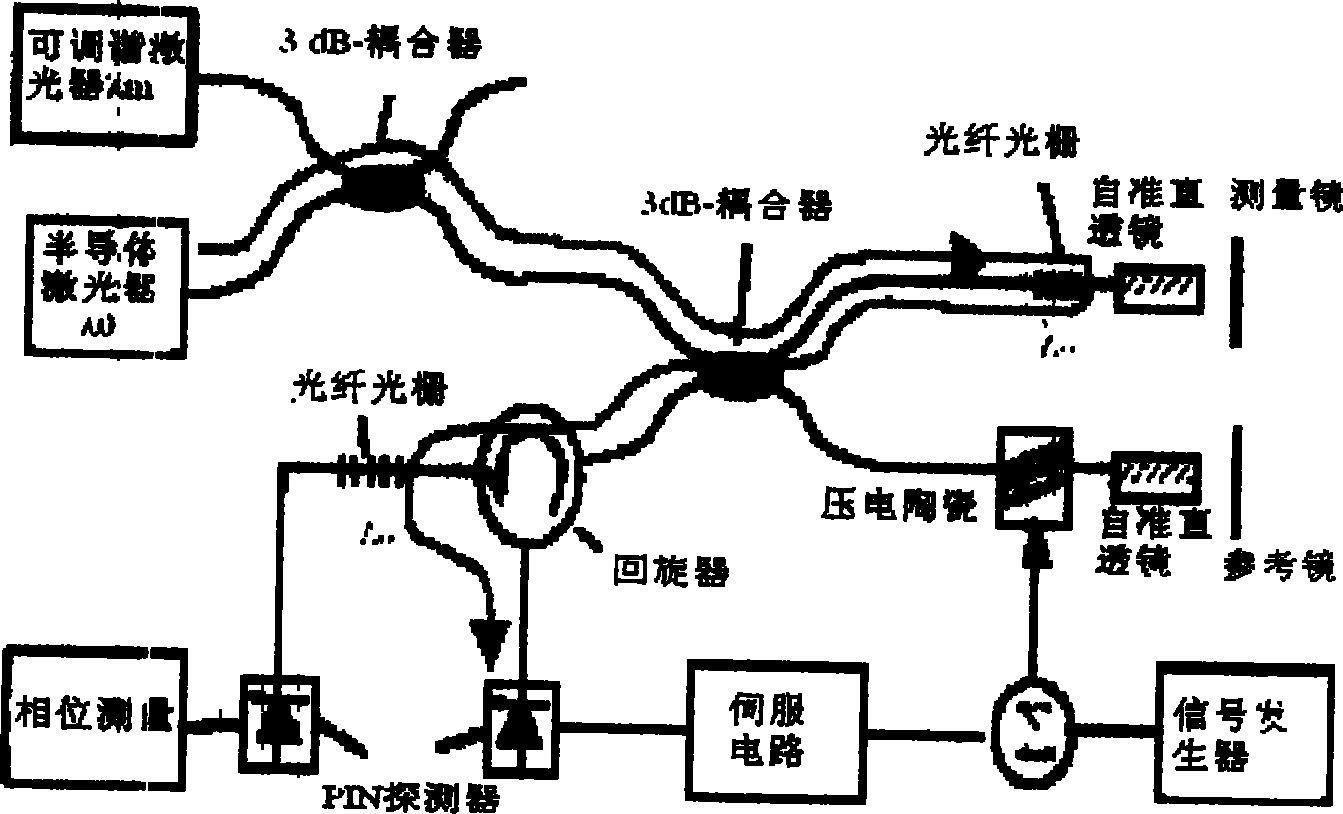

Step height on-line measuring system using optical fiber grating and wavelength-division multiplex technology

InactiveCN101126630ASuitable for online measurementExpand the range of interferometryUsing optical meansConverting sensor output opticallyOptical pathFeedback control

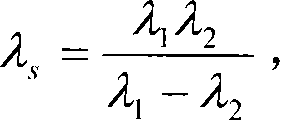

The utility model discloses an on-line measuring system for the bench height measuring system of the optical fiber grating and WDM technology. The utility model adopts the Bragg reflection wavelength property of fiber gratings and WDM technology to form a composite fiber interferometer, which comprises two fiber Michelson interferometers with nearly coincident reflector light paths; wherein, one interferometer is used for measuring, while the other is used for stabilizing, compensating the environmental interference to the measuring system through the feedback control circuit, thereby allowing the system to be applied to on-line measurement. The light emitted by the super radiation light emitting diode (LED) with the spectral width of 40 nm is reflected by three fiber gratings with different Bragg wavelengths into the light with three wavelengths. The light is sent into the system; wherein, one wavelength is used in stability interferometer to stabilize system, a second wavelength is used in measurement interferometer to produce a synthetic wave interference for measurement. Different sizes of synthetic wavelengths can be achieved through the regulation of two wavelengths of the measurement interferometer to realize bench height measurement to different heights.

Owner:BEIJING JIAOTONG UNIV

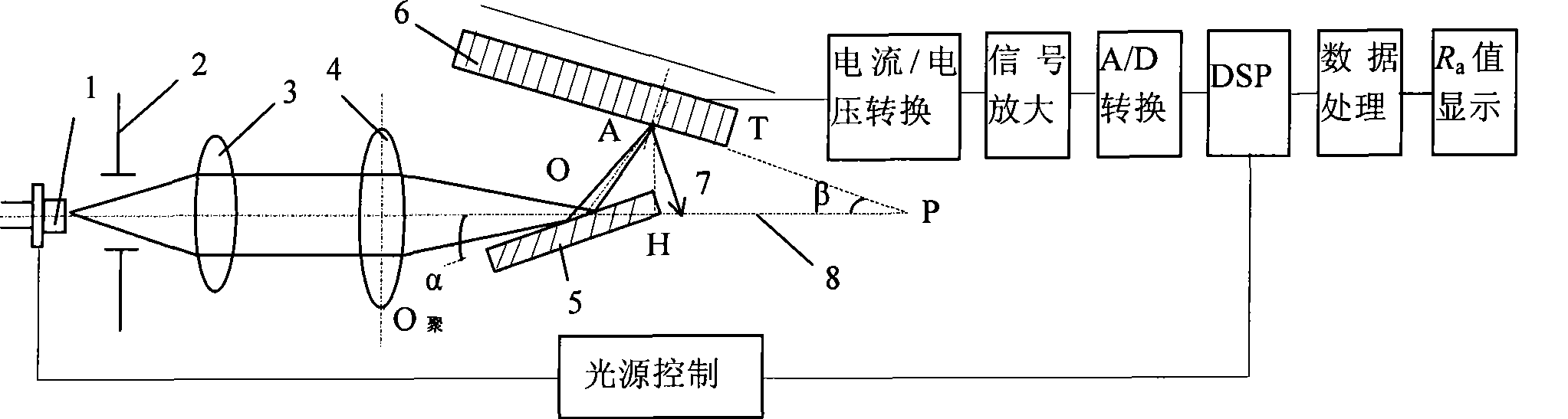

Detection device for roughness of surface

Owner:北京时代之峰佳亿科技有限责任公司

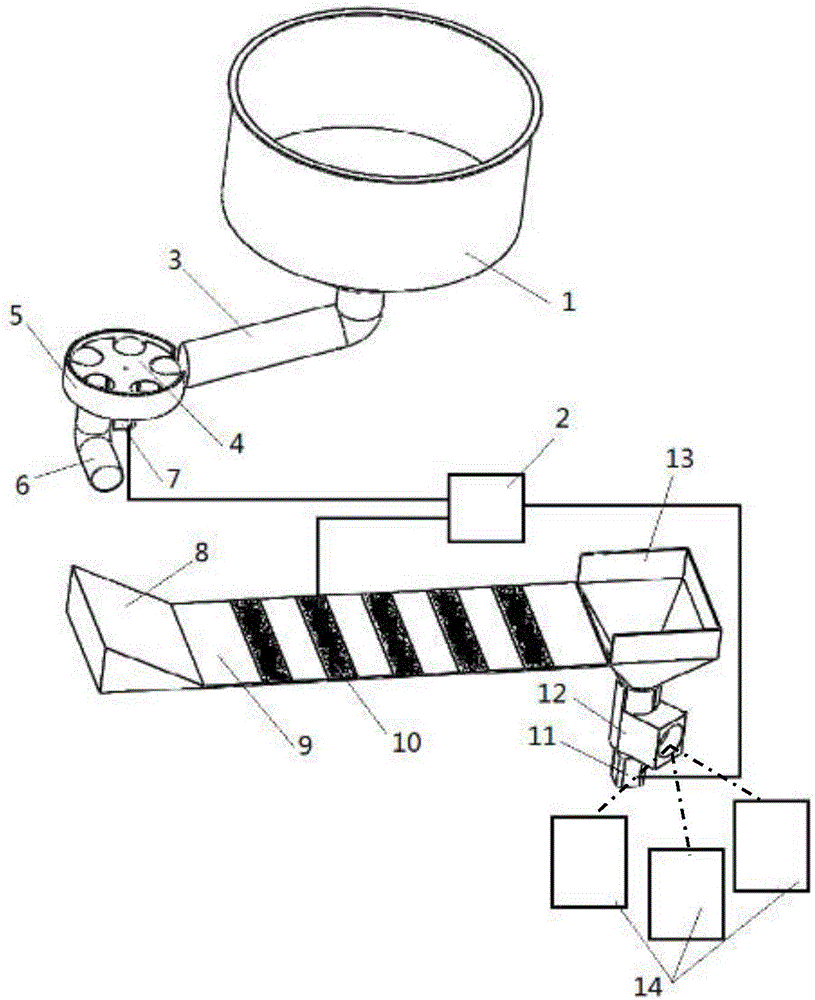

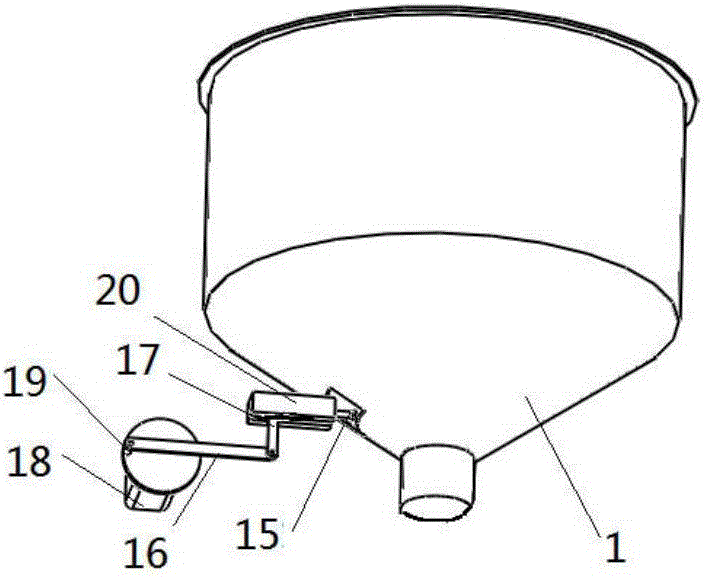

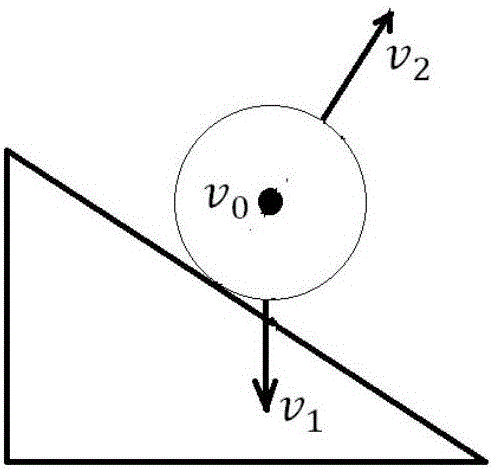

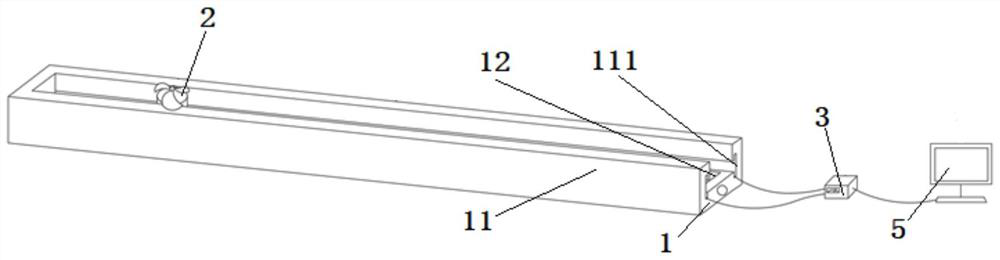

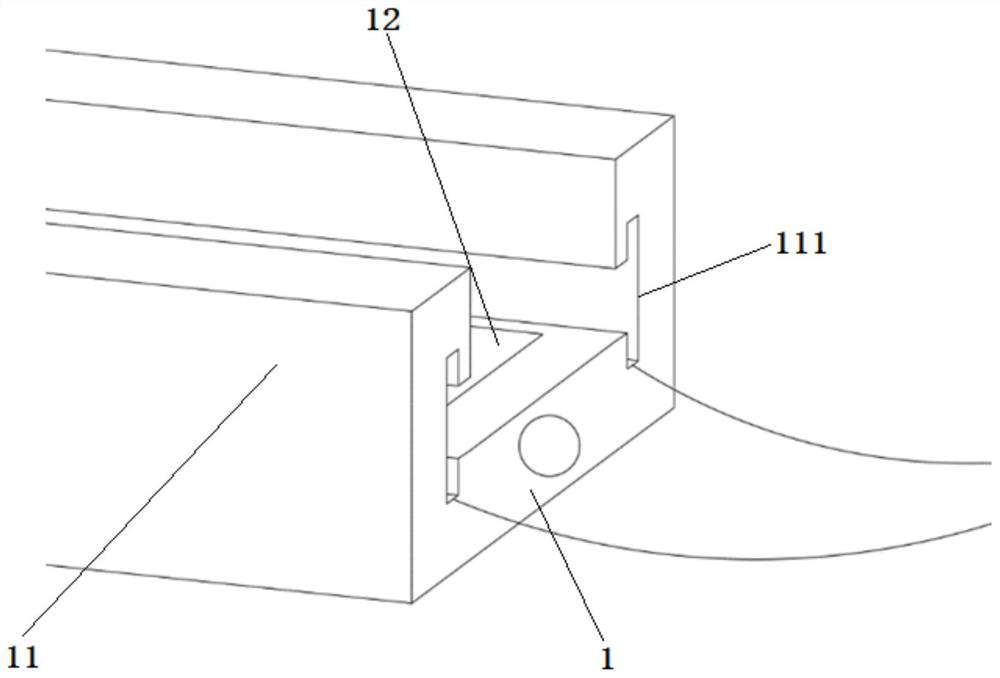

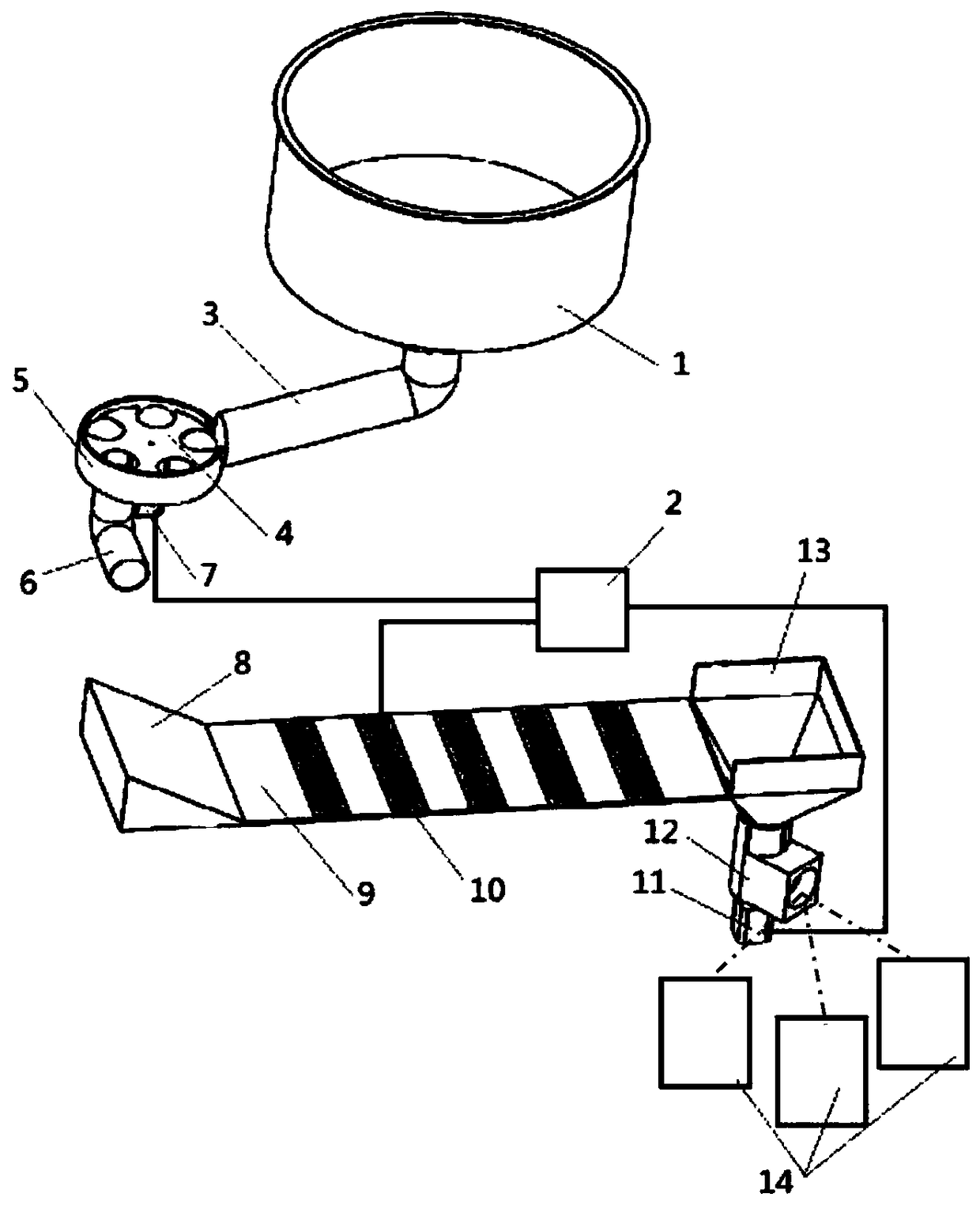

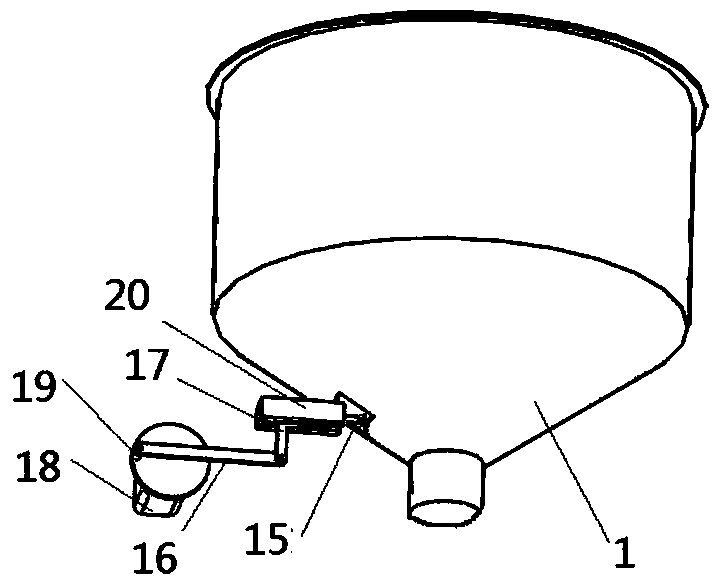

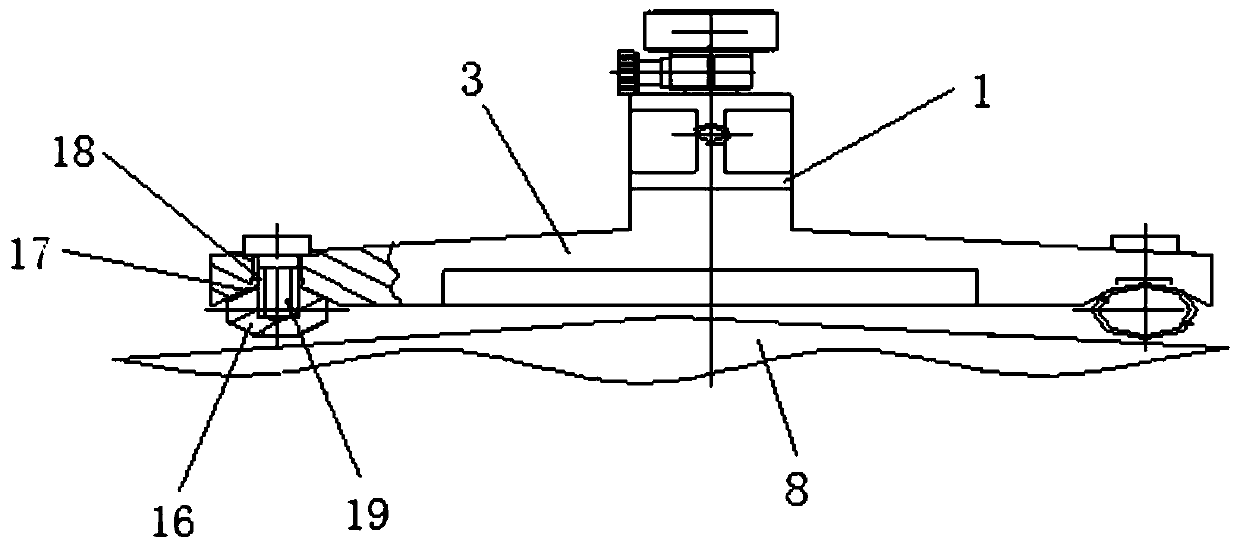

Seamless table tennis ball bounce performance detection and sorting device

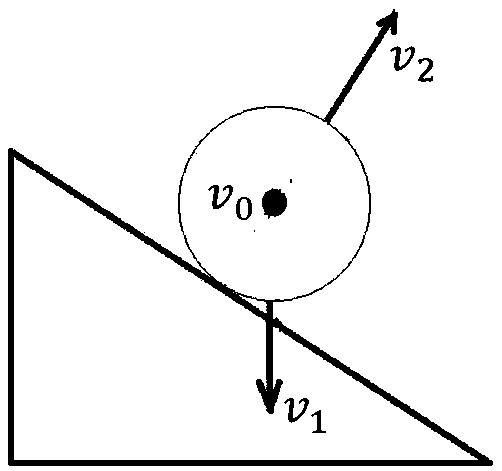

ActiveCN106345704ASimple structureEasy to operateSortingElasticity measurementEngineeringMechanical engineering

The invention discloses a seamless table tennis ball bounce performance detecting and sorting device, which comprises a ball supply device, a bounce device, a bounce collision information collection and treatment device and a ball collection device, wherein the ball supply device comprises a ball supply hopper, a discharge pipe, a ball supply rotary disk and a ball outlet elbow which are sequentially connected; the ball outlet elbow is provided with a ball inlet section and a ball outlet section, and the ball outlet section is horizontally arranged; the bounce device comprises a ball receiving bounce slope and a ball receiving bounce plane, the ball receiving bounce slope is arranged under the ball outlet elbow, and the normal direction of the ball receiving bounce slope is perpendicular to the axial space of the ball outlet section; the ball receiving bounce plane is arranged at the bottom of the ball receiving bounce slope and extends in the bounce forward direction of a table tennis ball; the bounce collision information collection and treatment device comprises a plurality of collision sensor and processors which are arranged on the ball receiving bounce plane in parallel. The seamless table tennis ball bounce performance detecting and sorting device can eliminate an effect of the falling initial velocity of the table tennis ball, eliminate errors generated by uneven bounce performance of different areas of a spherical surface of the table tennis ball and achieve real-time online detection.

Owner:TIANJIN UNIV

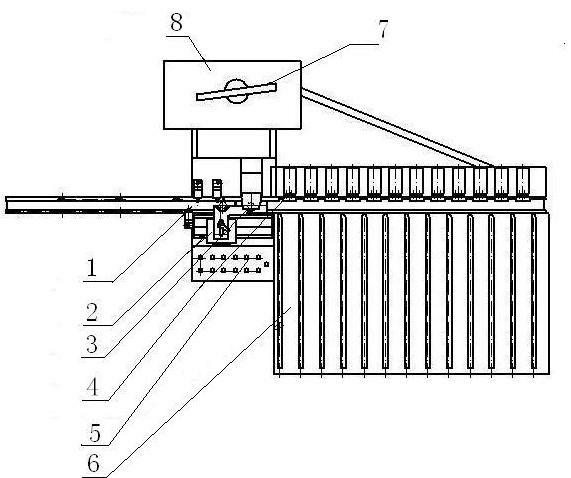

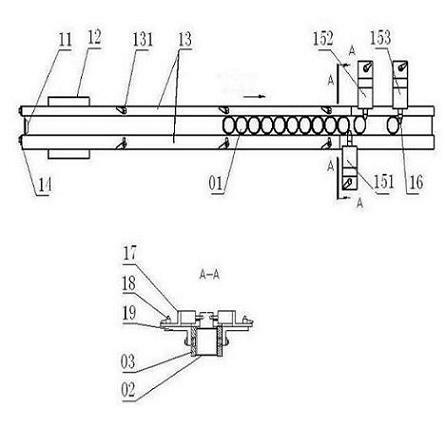

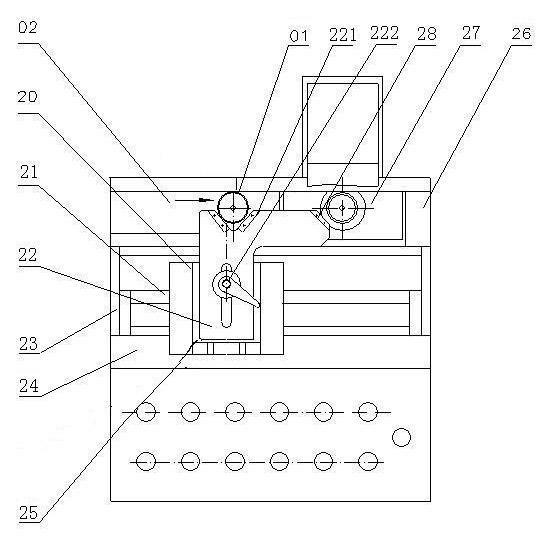

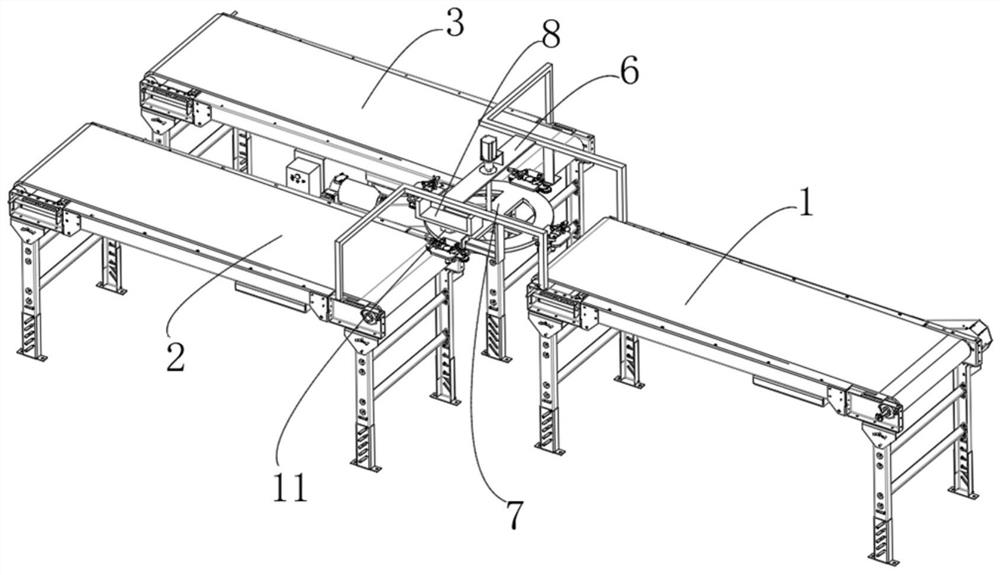

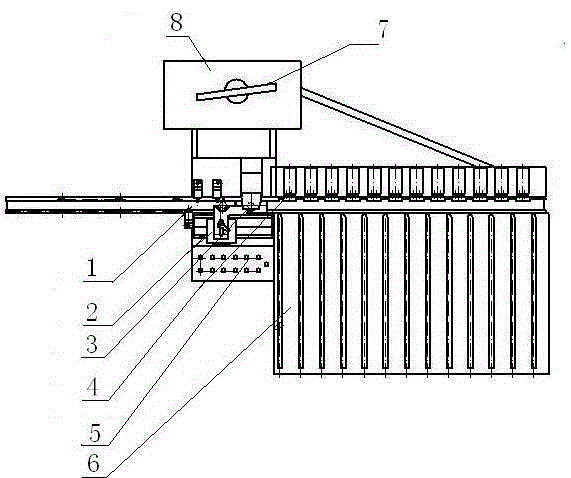

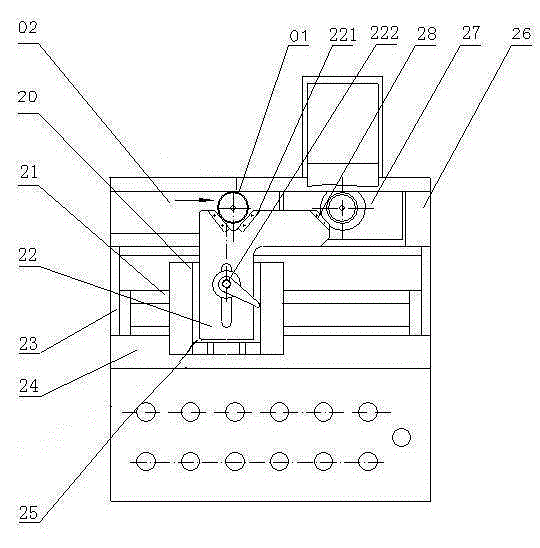

Automatic separator for valve tappet and valve shim

InactiveCN102133573AHigh repeatabilityIncrease the scope of applicationSortingProgrammable logic controllerEngineering

The invention relates to an automatic separator for a valve tappet and a valve shim, which is controlled by a PLC (Programmable Logic Controller) control system. The automatic separator is characterized in that a material distributing system is arranged, a feeding system is arranged one side of one end of the material distributing system, a measuring system is arranged at the opposite side of oneend of the material distributing system, and positioned behind the feeding system. A separating system is arranged behind the measuring system; the material distributing system and the separating system are respectively provided with a feeding conveyer belt and a separating conveyer belt which are arranged on the same plane; and the material distributing system, the feeding system, the measuring system and the separating system are connected into a whole. The automatic separator has higher repeatability, stability, measuring precision and measuring speed, is large in application range of a tested workpiece, can achieve the accurate and precise measurement and grouping on height of platform in the valve tappet and the valve shim, and is also suitable for on-line measurement.

Owner:邹国庆

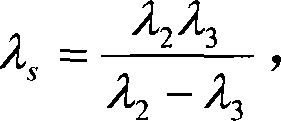

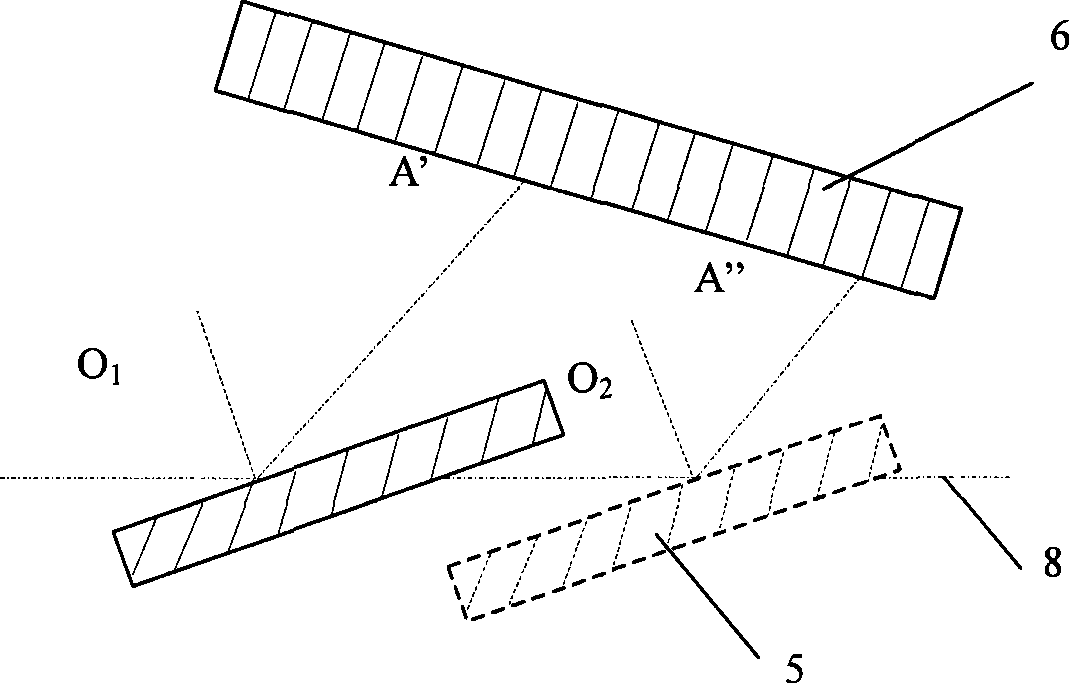

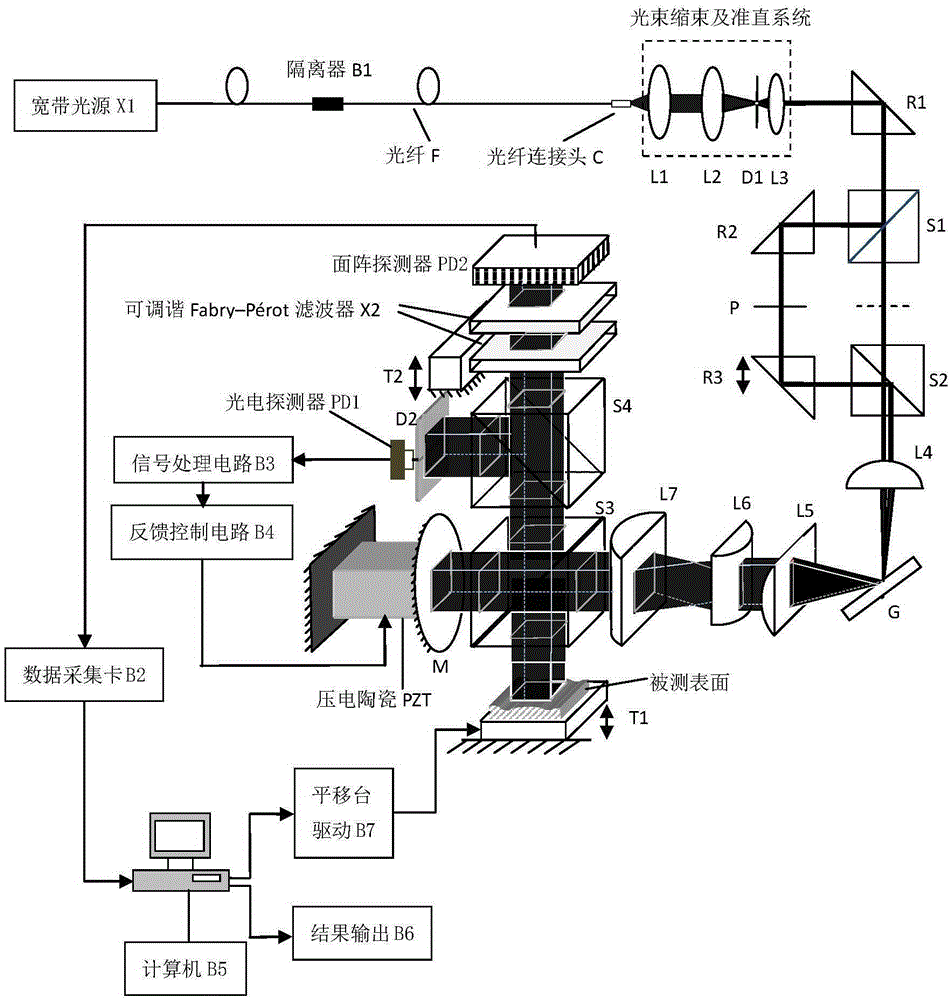

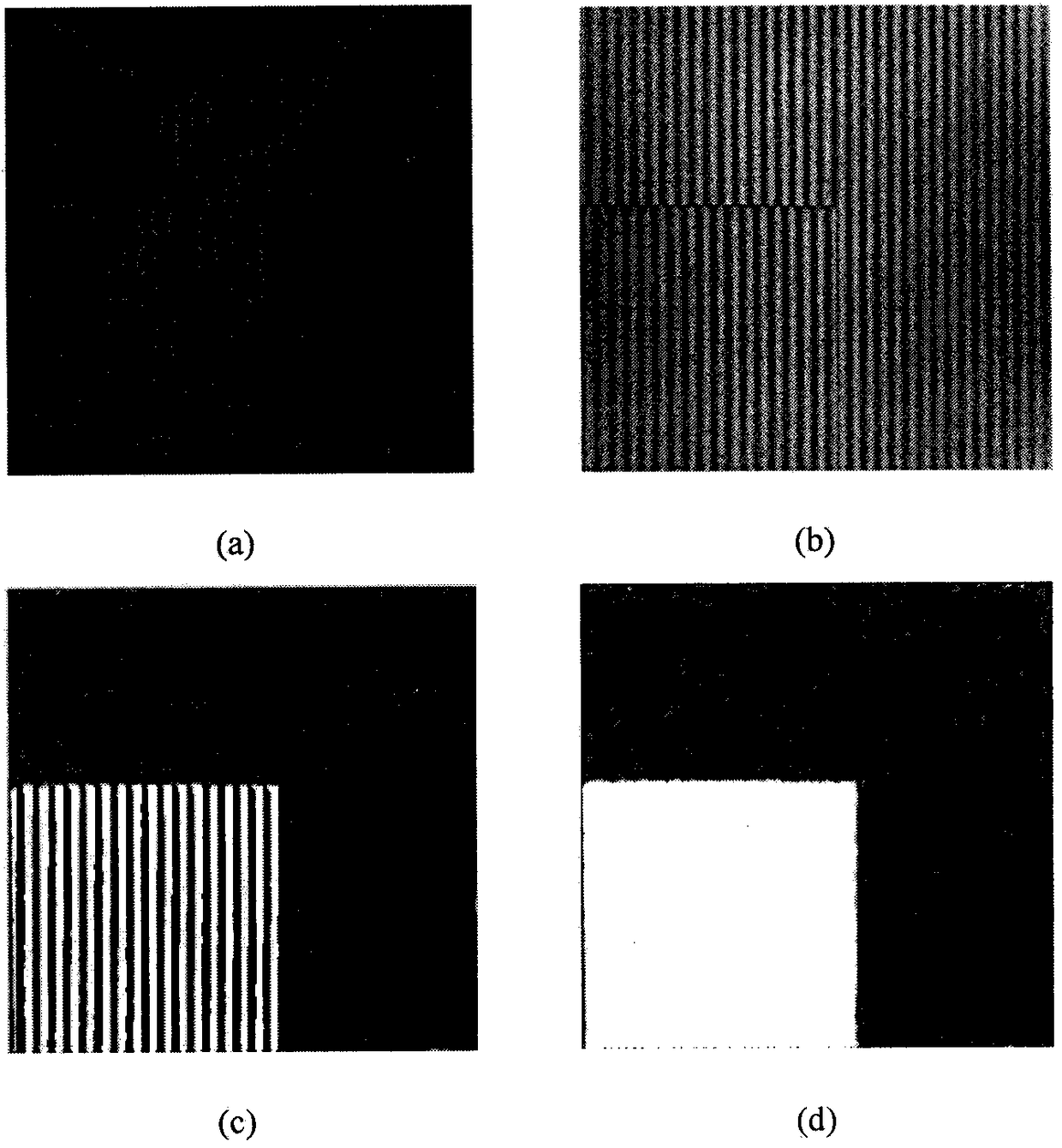

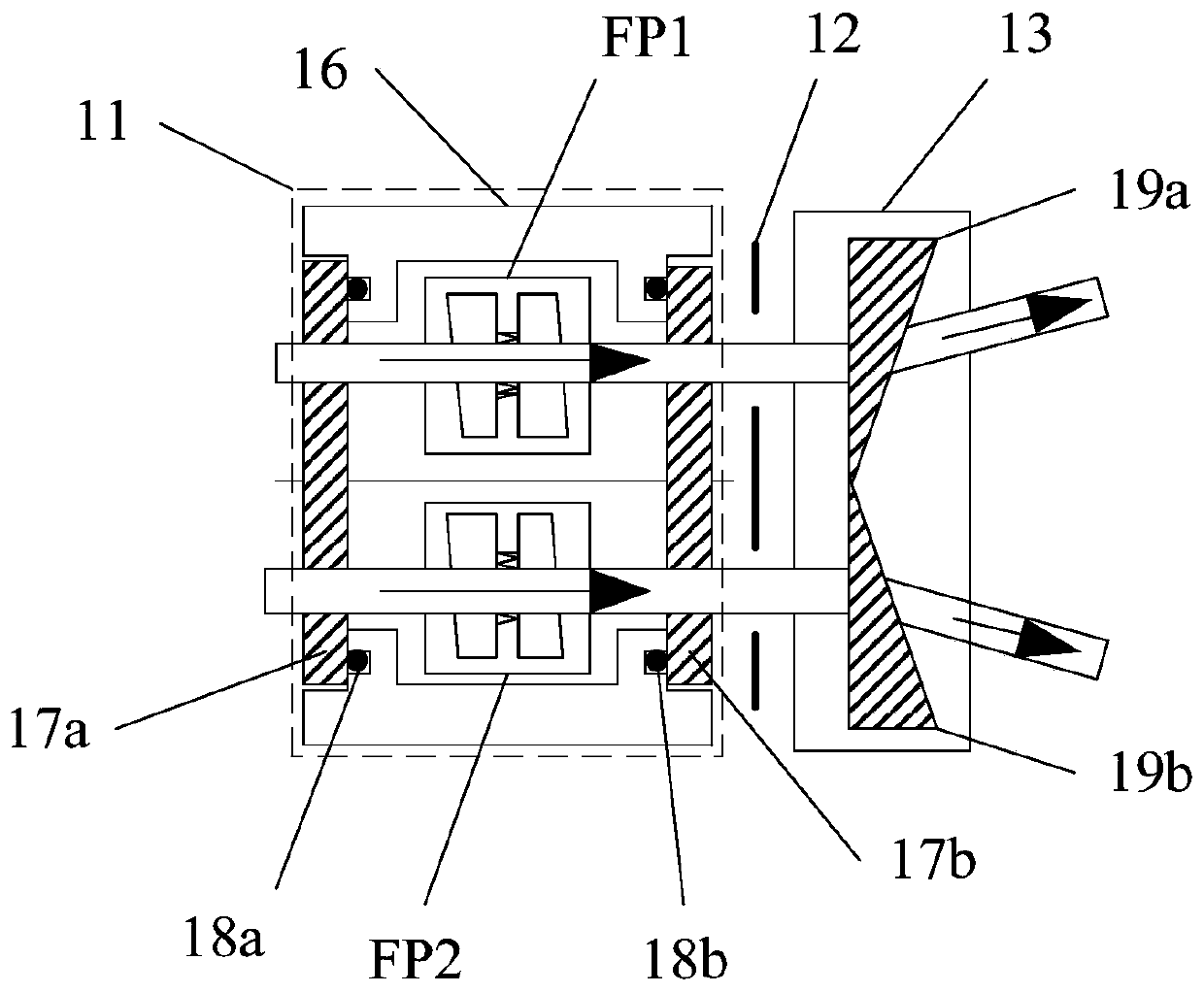

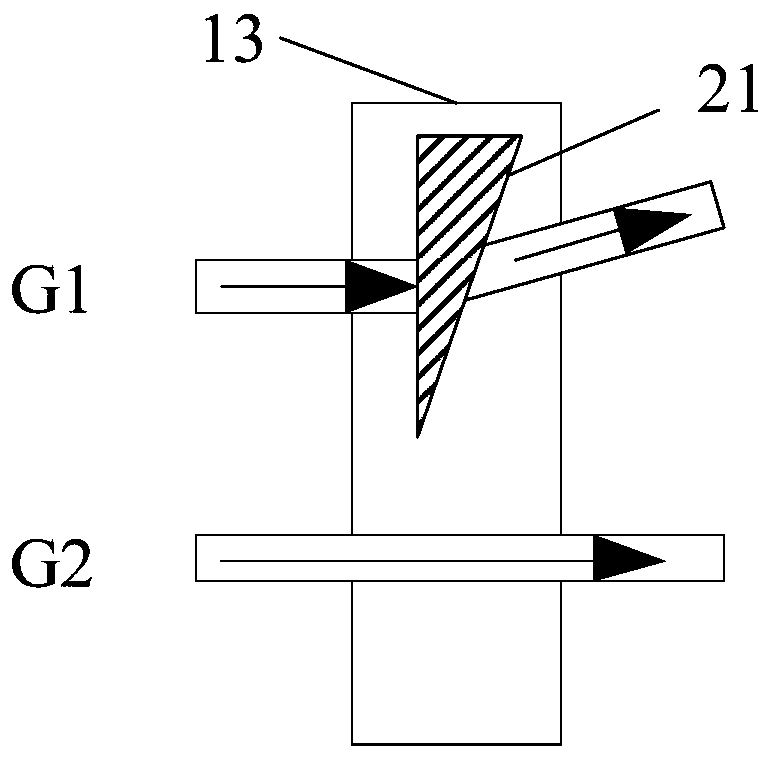

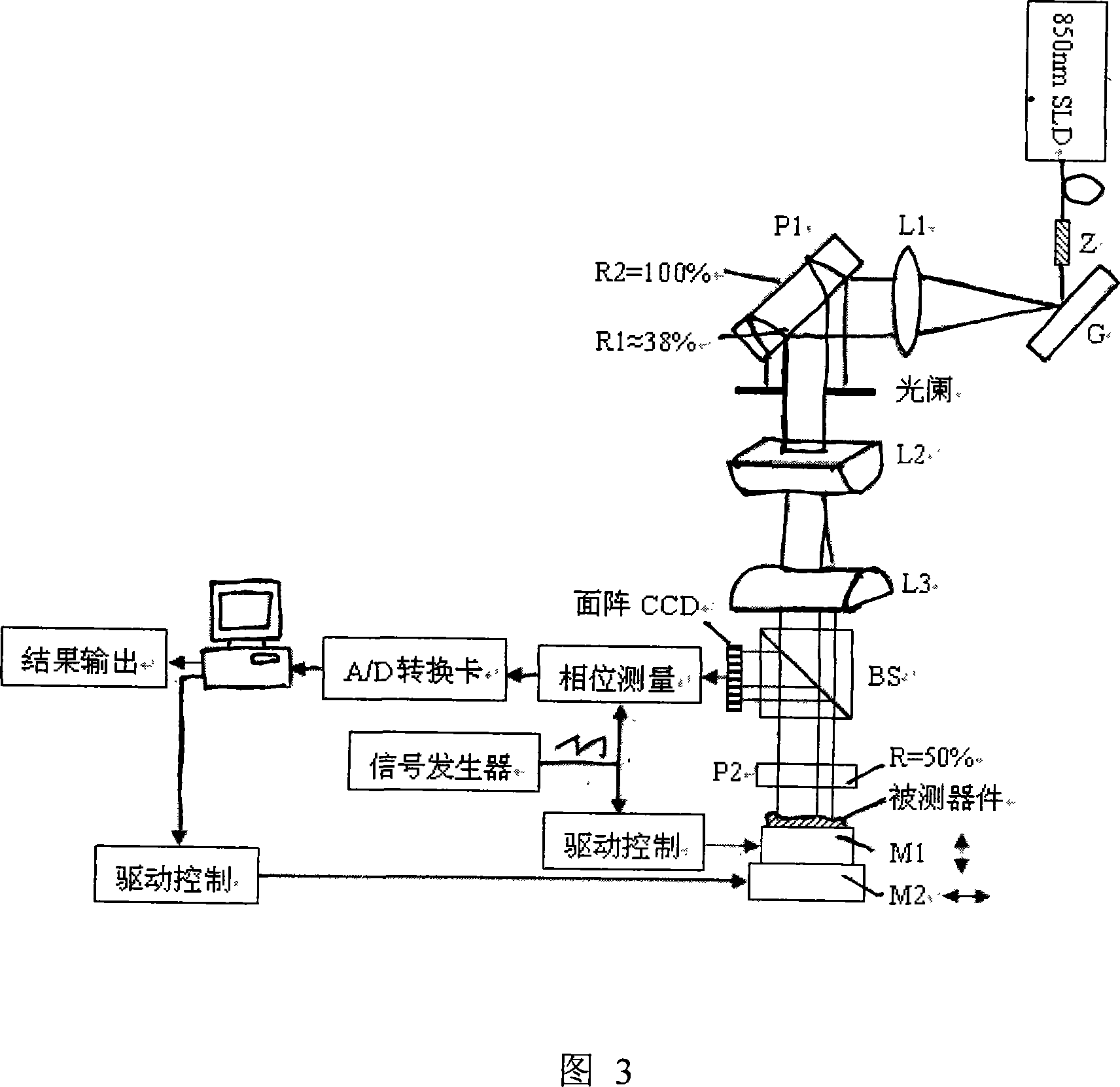

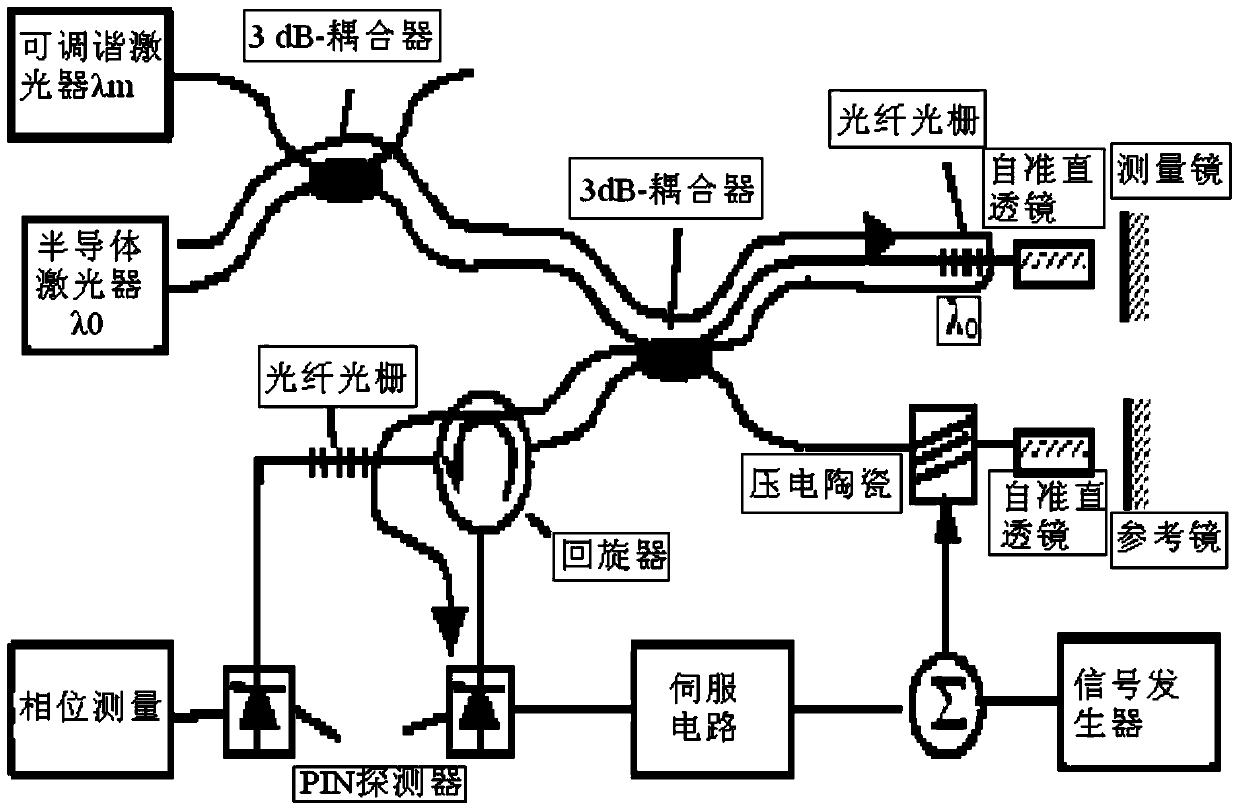

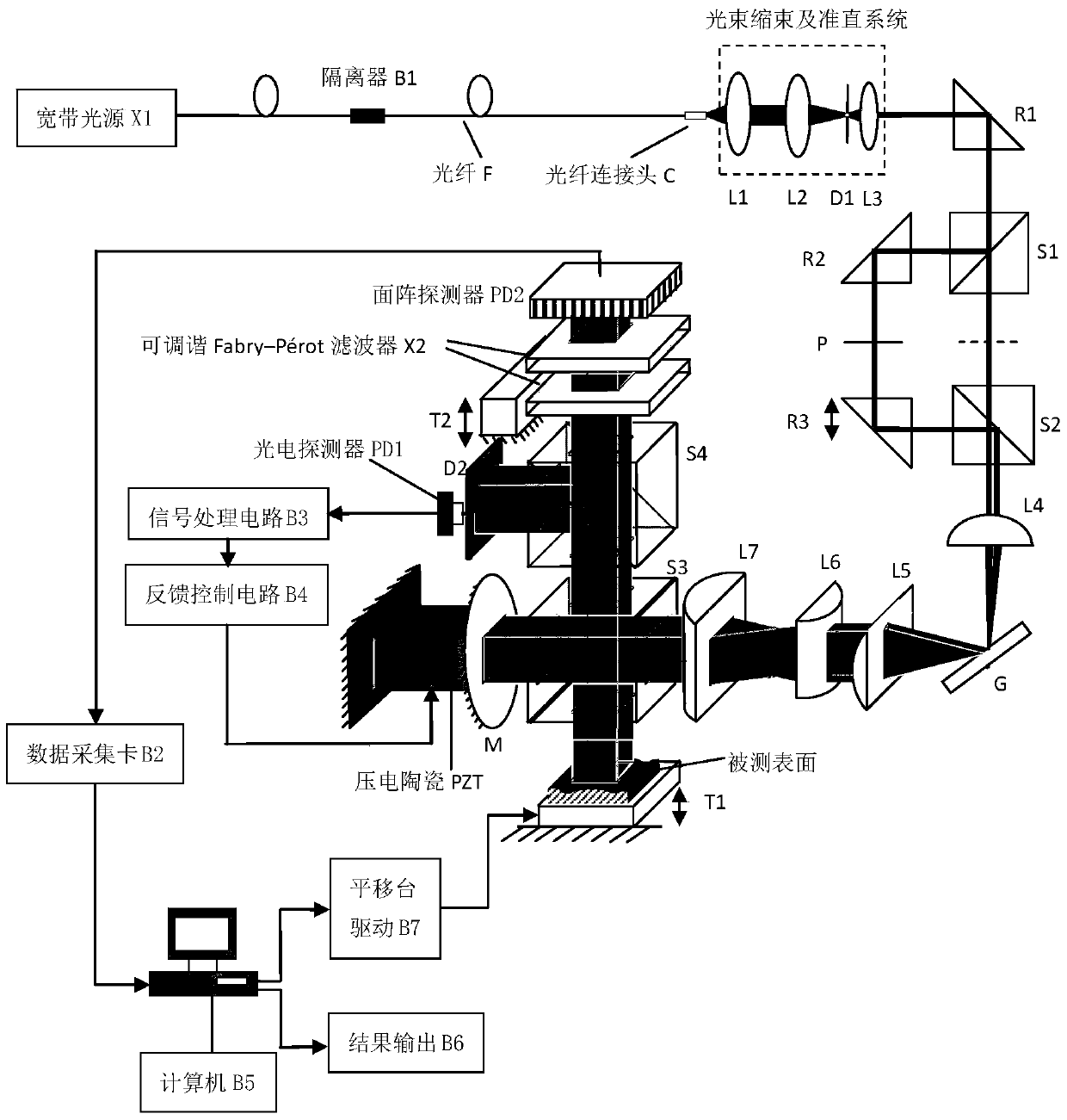

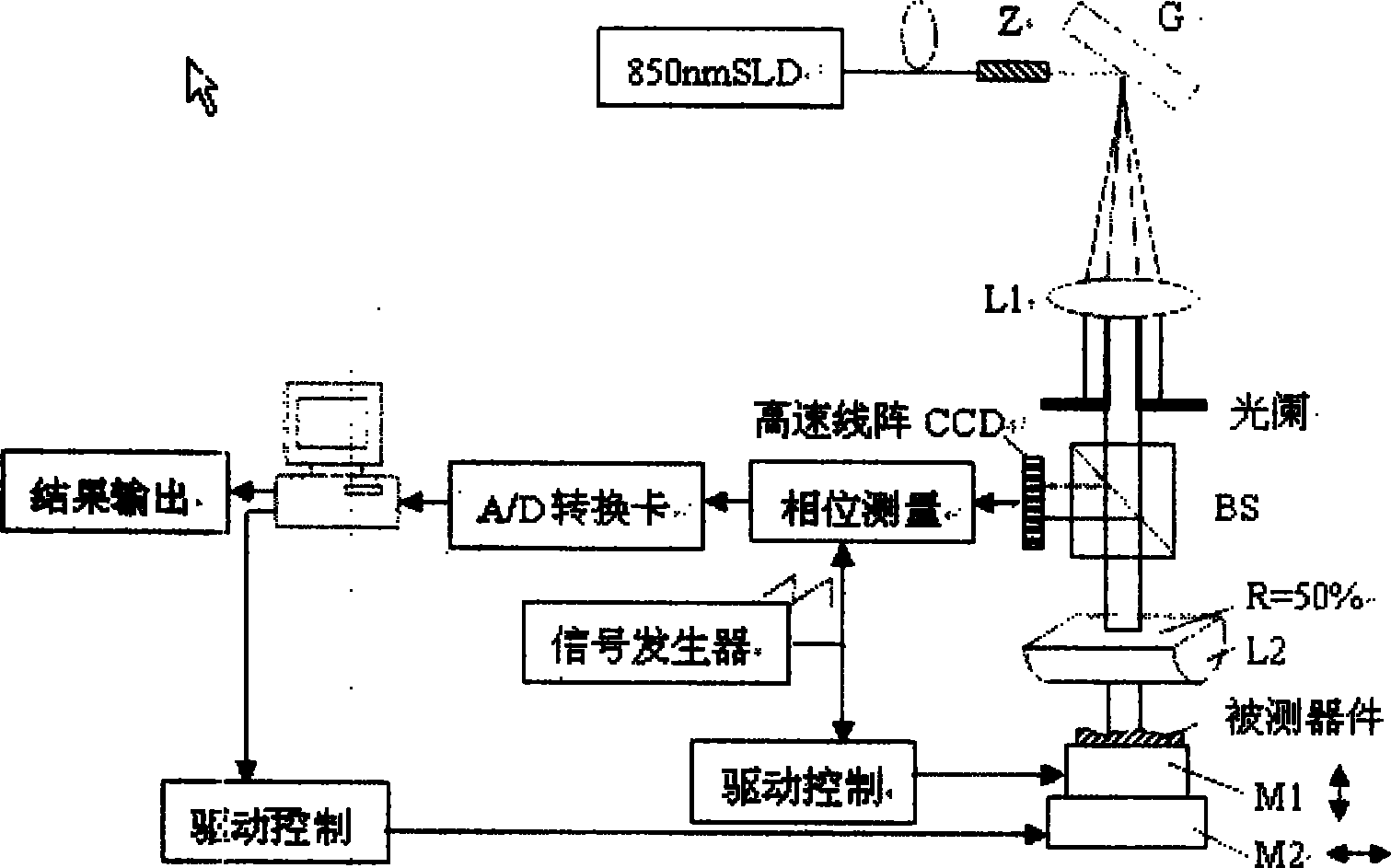

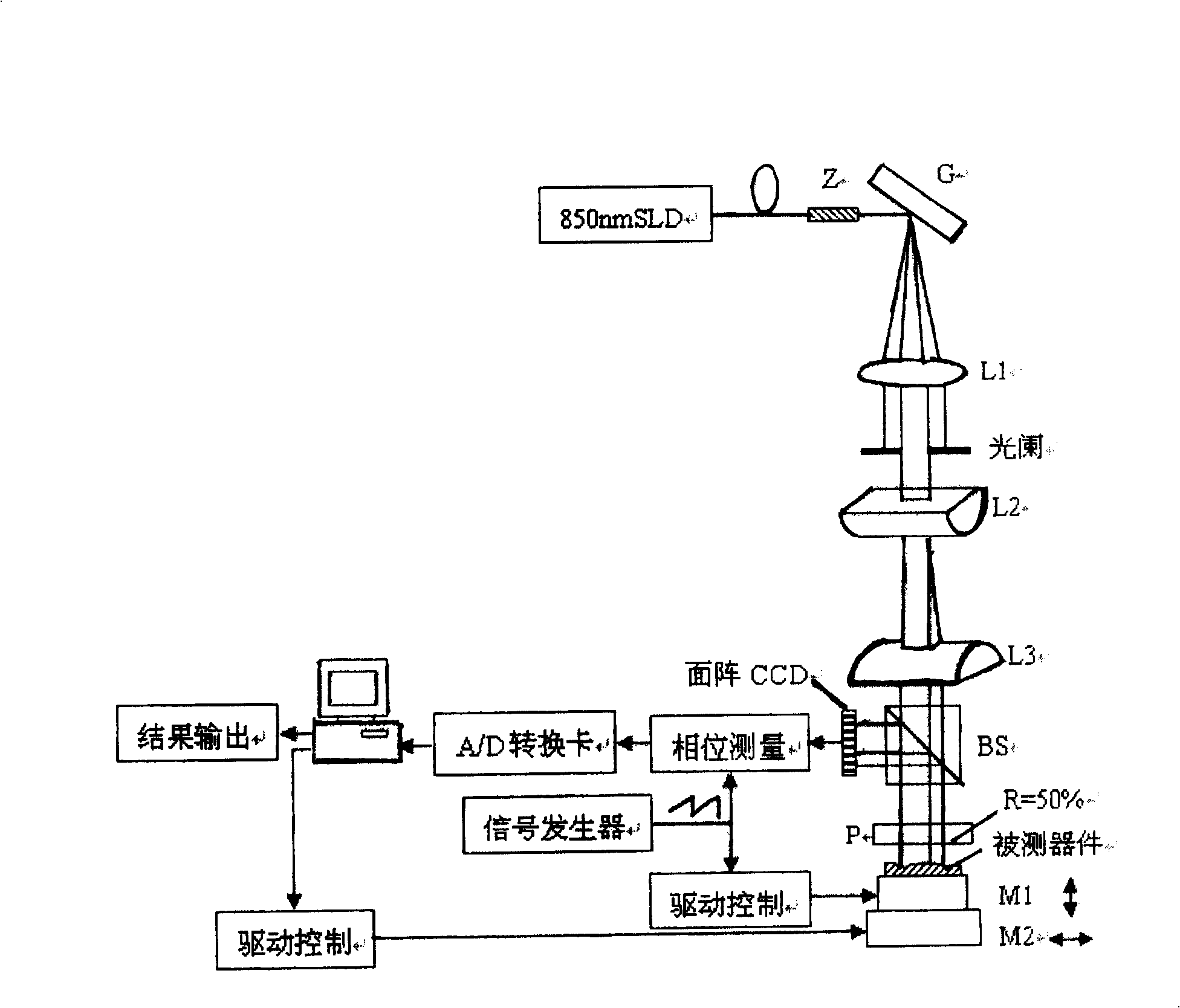

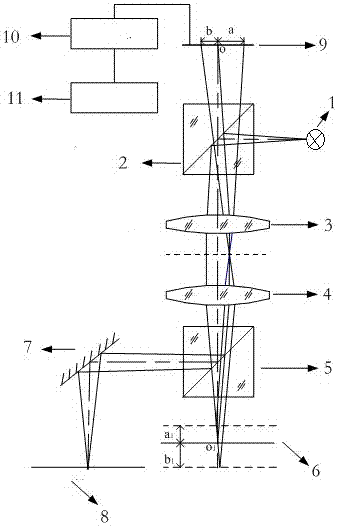

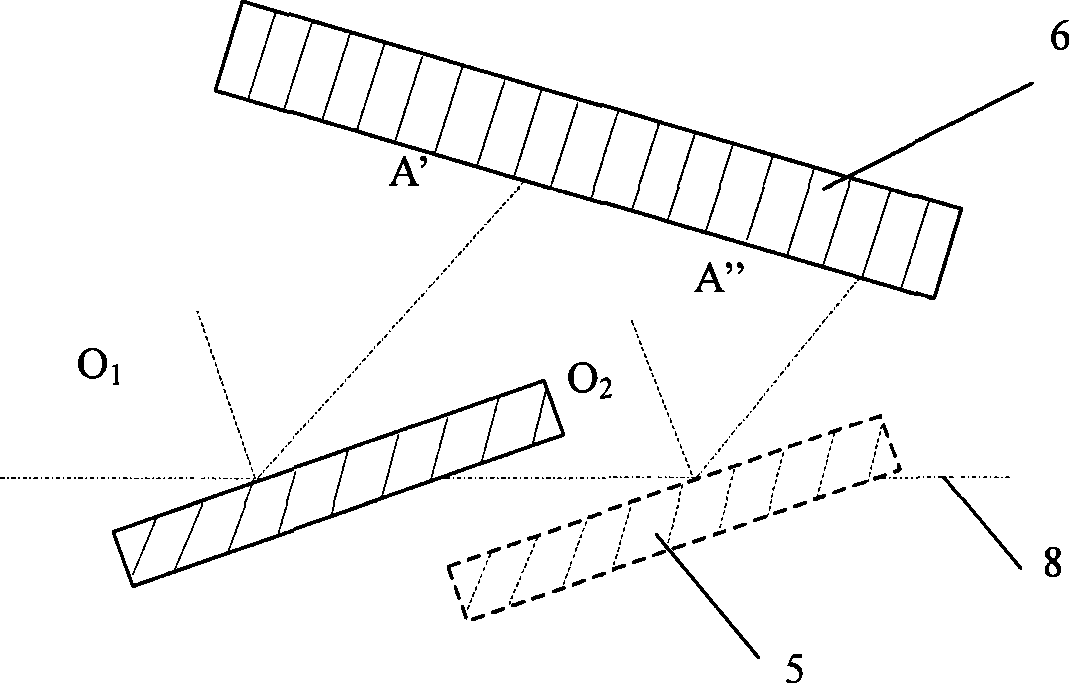

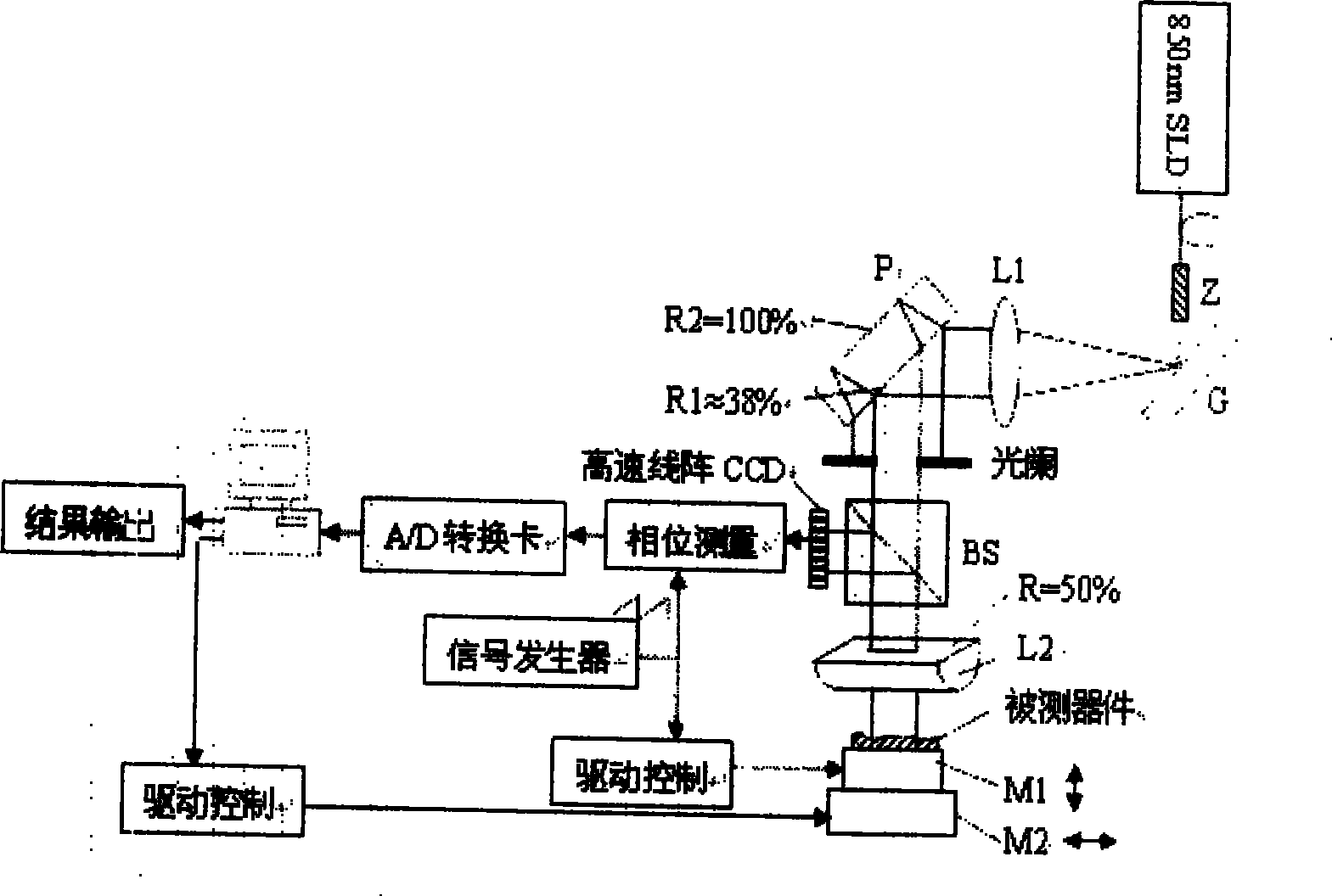

Super lateral resolution surface three-dimensional online interference measuring system based on spectral dispersion full field

ActiveCN105333816AImprove anti-interference abilityAccurate traceabilityUsing optical meansGratingSignal processing circuits

The invention discloses a super lateral resolution surface three-dimensional online interference measuring system based on a spectral dispersion full field, and belongs to the field of optical measurement. The system is composed of a broadband light source, an isolator, a fiber, a fiber joint, a spherical-surface and cylindrical-surface spectroscopes, spectroscopes, right-angle prisms, diaphragms, a raster, a reflector, a surface array detector, a photoelectric detector, a Fabry-Perot filter, piezoelectric ceramics, a signal processing circuit, a feedback control circuit, a data acquisition card, a computer, translation benches, a translation bench driving part, a result output part and the like. The raster disperses a broadband spectrum to form a mating plate whose wavelength is continuously distributed in a transverse direction, and the mating plat is incident vertically to a measured surface through beam expansion for full-field measurement; a surface provided with a step whose height difference is greater than a half-wavelength and a large-depth-to-width-ratio groove is measured by use of two wavelengths; super lateral resolution measurement is realized by use of the Fabry-Perot filter; and ambient interference is compensated through feedback control, the system is enabled to be suitable for online measurement, the measuring result can be accurately traced to a wavelength reference, and the influence of the drift of a light source spectrum is eliminated.

Owner:BEIJING JIAOTONG UNIV

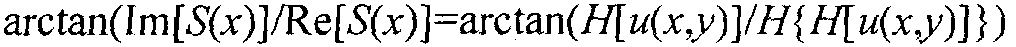

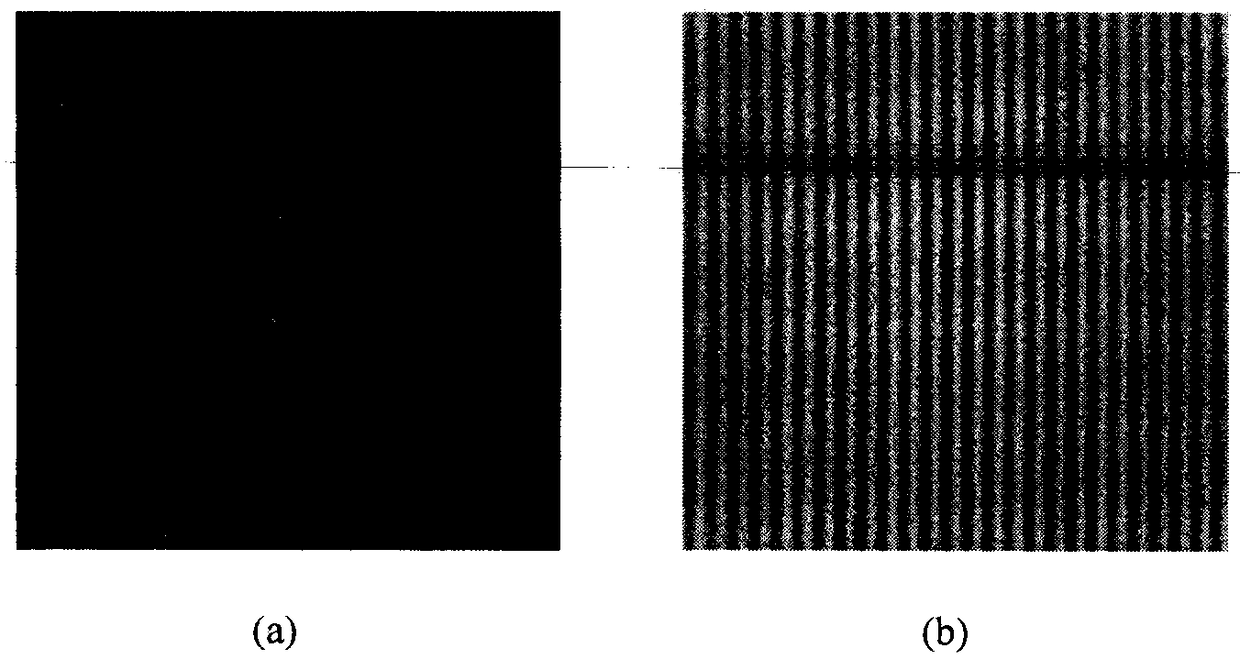

Phase extraction method of optical fiber interference fringe image based on Hilbert transform

The invention discloses a phase extraction method of an optical fiber interference fringe image based on a Hilbert transform. According to the phase extraction method of the optical fiber interferencefringe image based on the Hilbert transform, fast and accurate phase extraction can be realized only by capturing a fringe image, and the phase information extraction speed and precision are effectively improved compared with the existing method. The method comprises the following steps of: (1) capturing a fringe structured light image projected by the optical fiber interferometer through an areaarray camera and a deformed fringe image modulated by the measured object; (2) performing a first Hilbert transform after the gradation transformation process to obtain a new image that filters out adirect current component and is in an orthogonal relationship with the image before transformation; (3) performing a second Hilbert transform process on the new image to obtain a final image in an orthogonal relationship with the first transformed image; (4) constructing an analytic signal according to the sine component and the cosine component of the image obtained by the two transformations; and (5) obtaining phase information of the interference fringe image based on the analytic signal.

Owner:TIANJIN POLYTECHNIC UNIV

Device and method for measuring coaxiality

ActiveCN104776816AHigh measurement accuracyThe effect of the surface shape of the objectUsing optical meansOptical pathPrism

The invention discloses a device and a method for measuring coaxiality. The device comprises a light source and a first beam splitting prism which is arranged on the emitting face of the light source. A first lens, a second lens and a second beam splitting prism are sequentially arranged below the first beam splitting prism. A first detected shaft is arranged below the second beam splitting prism. A plane reflecting mirror which is arranged by an angle of 45 degrees is arranged to the left of the second beam splitting prism. A second detected shaft is arranged below the plane reflecting mirror. A CCD detector is arranged above the first beam splitting prism. The CCD detector is electrically connected with a processor. The processor is electrically connected with a computer. The method comprises the following steps that firstly, a light path is constructed; secondly, the CCD detector is calibrated; thirdly, the light path is regulated; fourthly, reflected light tracks of the first detected shaft and the second detected shaft are imaged on the CCD detector and are output to the computer through the processor; fifthly, track matching is carried out by the computer, a coaxiality value is obtained by calculating. The theory is simple, the implementation is strong, the stability is good, the advantages of the automation and the intelligence are achieved, and online measuring can be carried out on the coaxiality.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

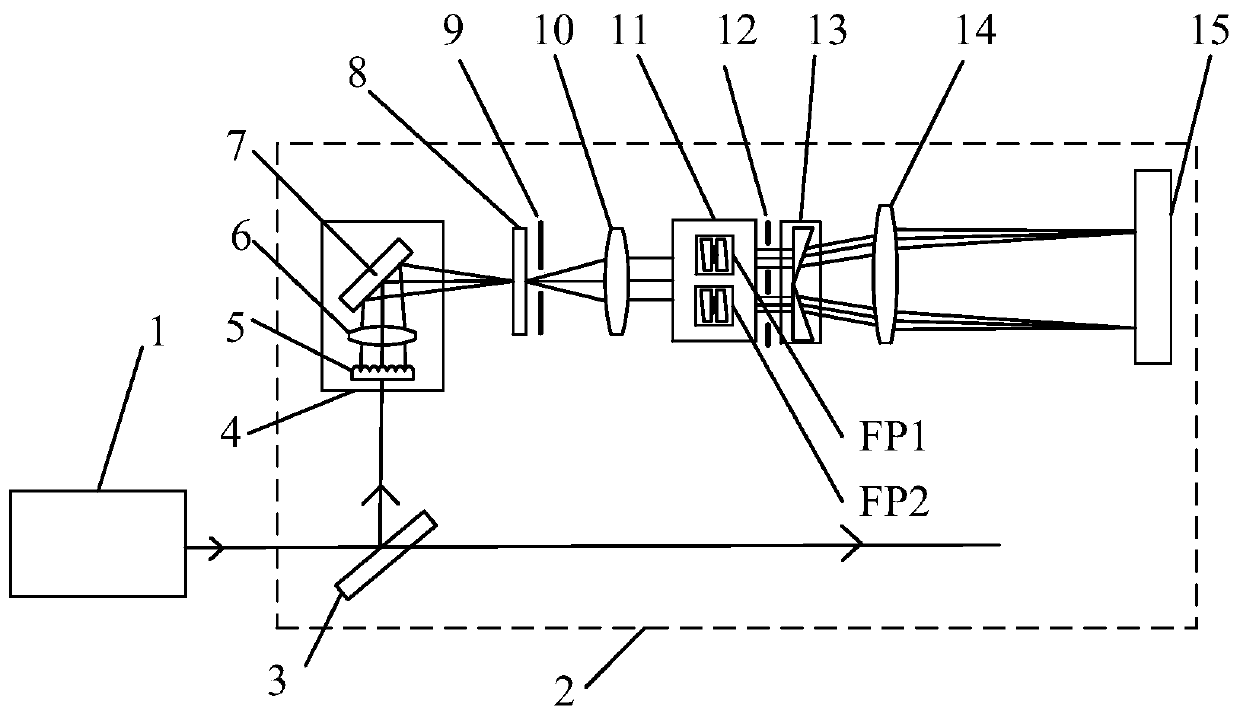

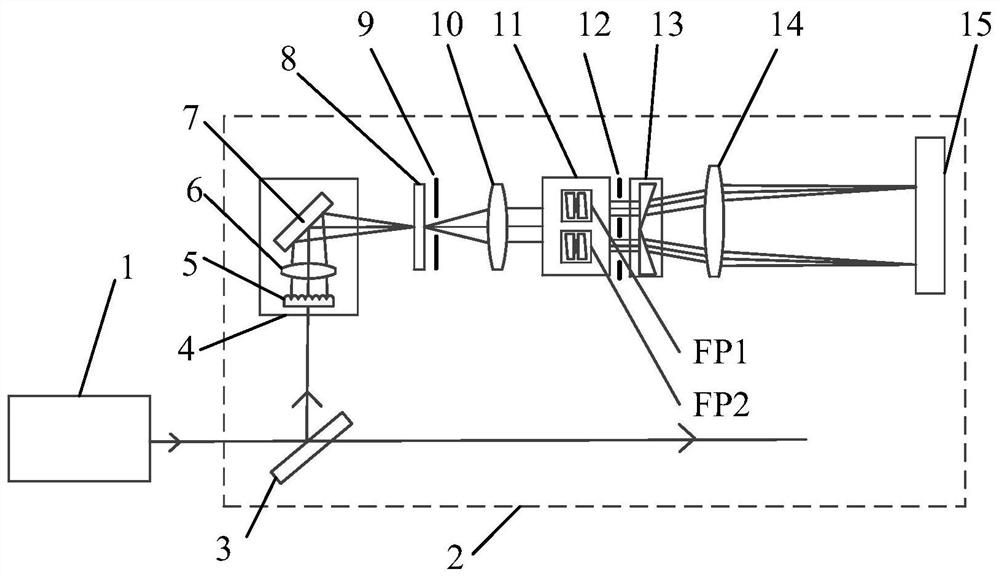

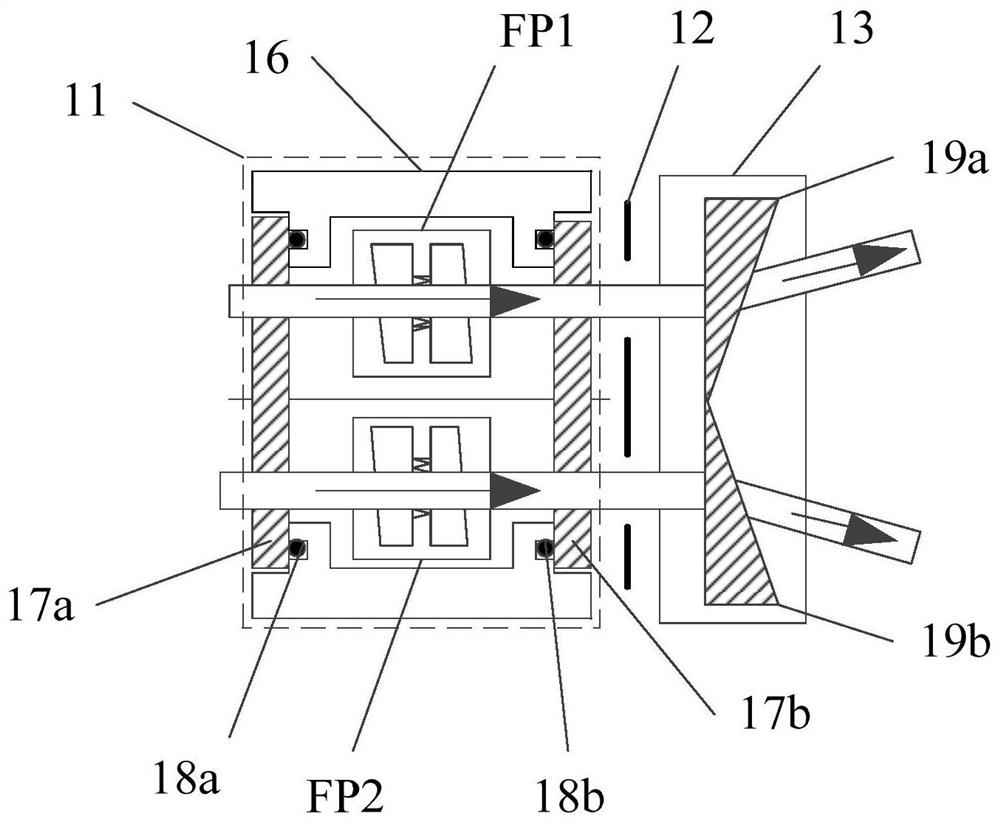

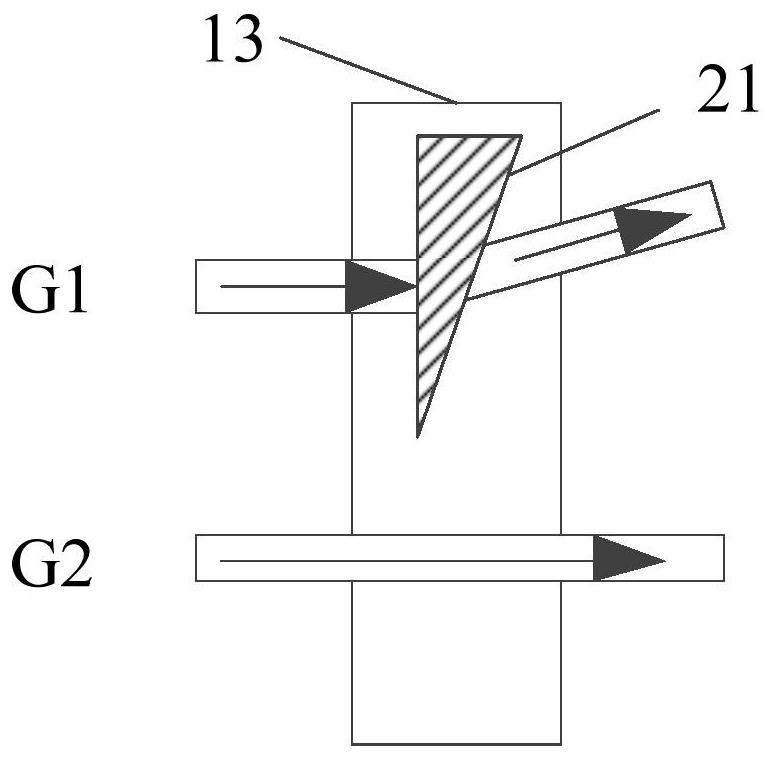

Laser wavelength measuring device and method

ActiveCN111289124AHierarchical imaging facilitatesCompact structureOptical measurementsPhotomechanical apparatusFirst lightLight beam

The invention discloses a laser wavelength measuring device and method. The laser wavelength measuring device comprises a first light path assembly and a second light path assembly; the second light path assembly and the first light path assembly form a laser wavelength measurement light path; the second light path assembly comprises an FP etalon assembly and an optical grader, wherein the homogenized laser beams pass through the FP etalon assembly to generate interference fringes; the optical grader is arranged behind the FP etalon assembly in the laser wavelength measurement light path and is used for deflecting the laser beams passing through the FP etalon assembly. According to the FP etalon assembly, the two FP etalons share the same optical path for interference imaging; the structure is compact, the size is small, the design is simple, and the stability is high; under the cooperation of the optical grader, the laser wavelength can be accurately measured at the same time, the wavelength measurement range is large, and the device is suitable for online measurement of the laser wavelength and corresponding closed-loop control feedback.

Owner:RAINBOW SOURCE LASER RSLASER

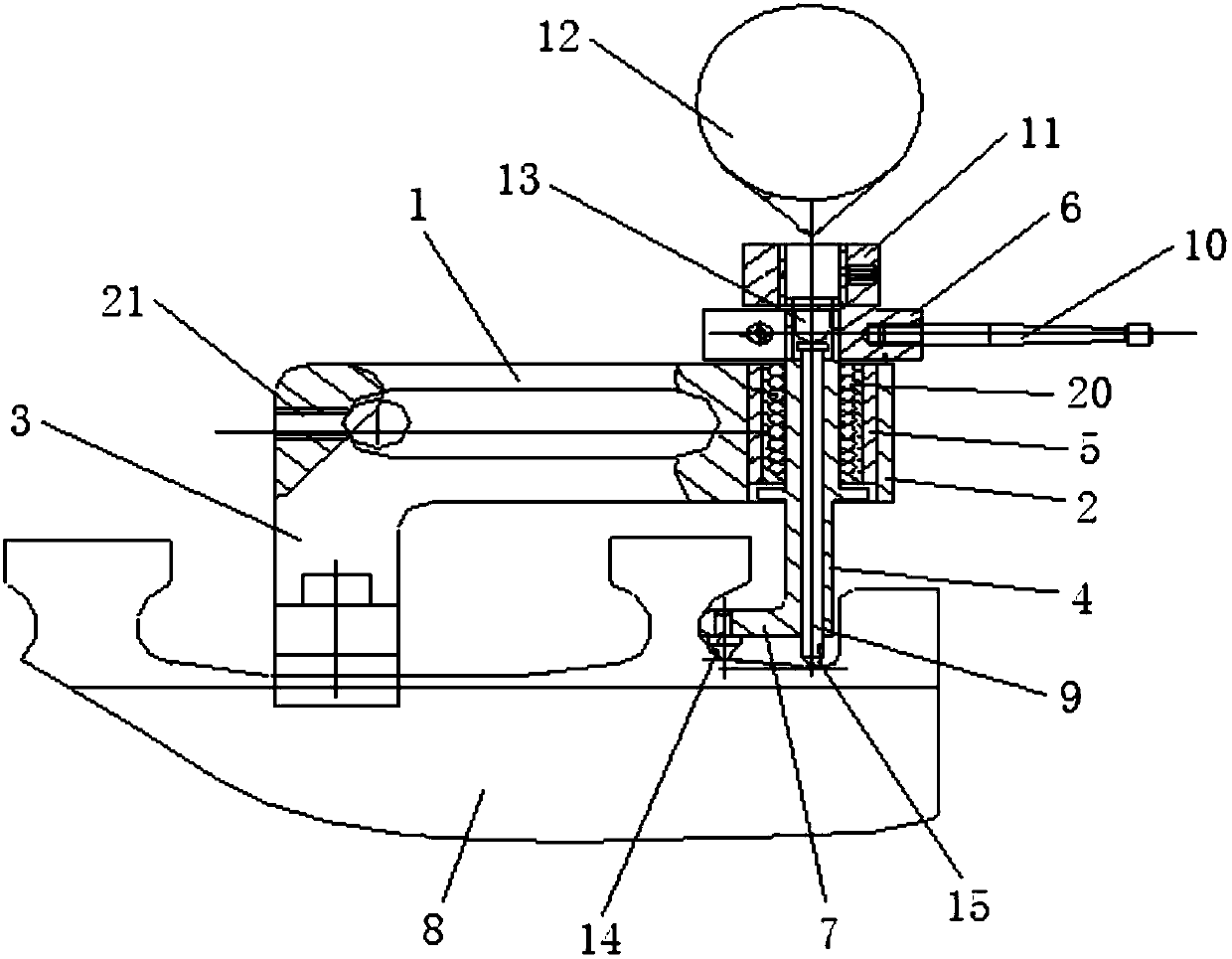

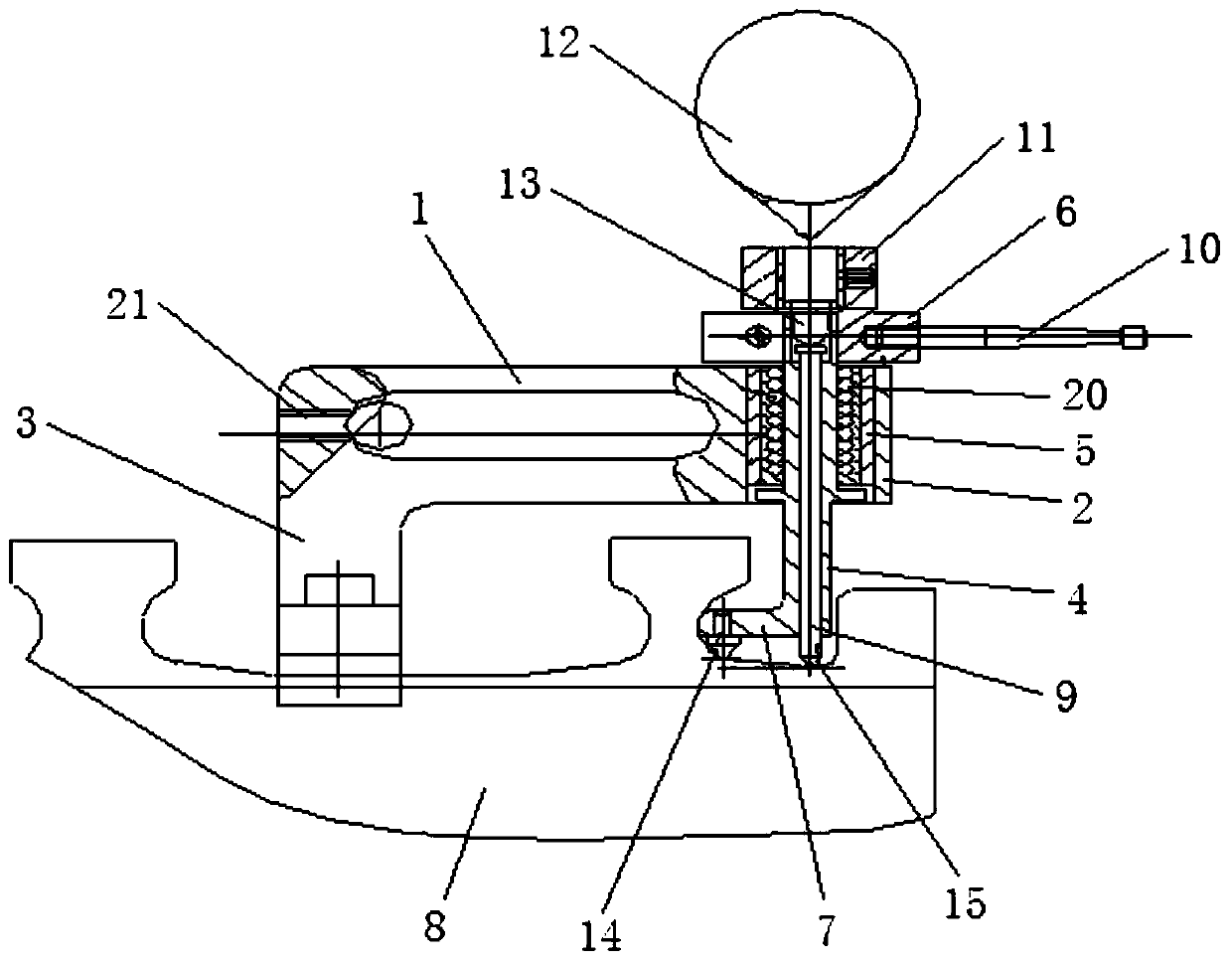

Mechanism for rapid measurement of cartridge receiver outer wall radial difference and application method thereof

ActiveCN108020137AAvoid measurement interference problemsEasy and fast measurementMechanical measuring arrangementsFast measurementDimension measurement

The present invention provides a mechanism for rapid measurement of a cartridge receiver outer wall radial difference and an application method thereof. A movable measurement portion employs a linearbearing installed in a measuring body to achieve axial and circumferential motion. The rotation and the radial sliding of the measurement portion in the measuring body solve the stroke problem of measurement of an inner cavity. A fixed measuring rod provided with a sliding measuring rod performs stable and barrier-free sliding on the linear bearing, so that it is ensured that the sliding measuringrod and the fixed measuring rod are located in the same line and unstable factors caused by man-made force application measurement can be eliminated. The measurement effect is high and the measurement data is sensitive, the measurement for the dimensions of the inner portion of the cavity is convenient and rapid, the production efficiency is improved, the application effect is good. The mechanismfor rapid measurement of the cartridge receiver outer wall radial difference and the application method thereof have practical application values, can effectively avoid a problem of interference on measurement caused by parts, and can accurately and rapidly measure the cartridge receiver outer wall radial difference. The measurement method is simple and convenient and rapid in operation. Meter setting is performed on a standard piece when in measurement, detection is performed on a cartridge receiver part to be measured, and the measurement mode is relative measurement to improve the measurement precision and to improve the production efficiency.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

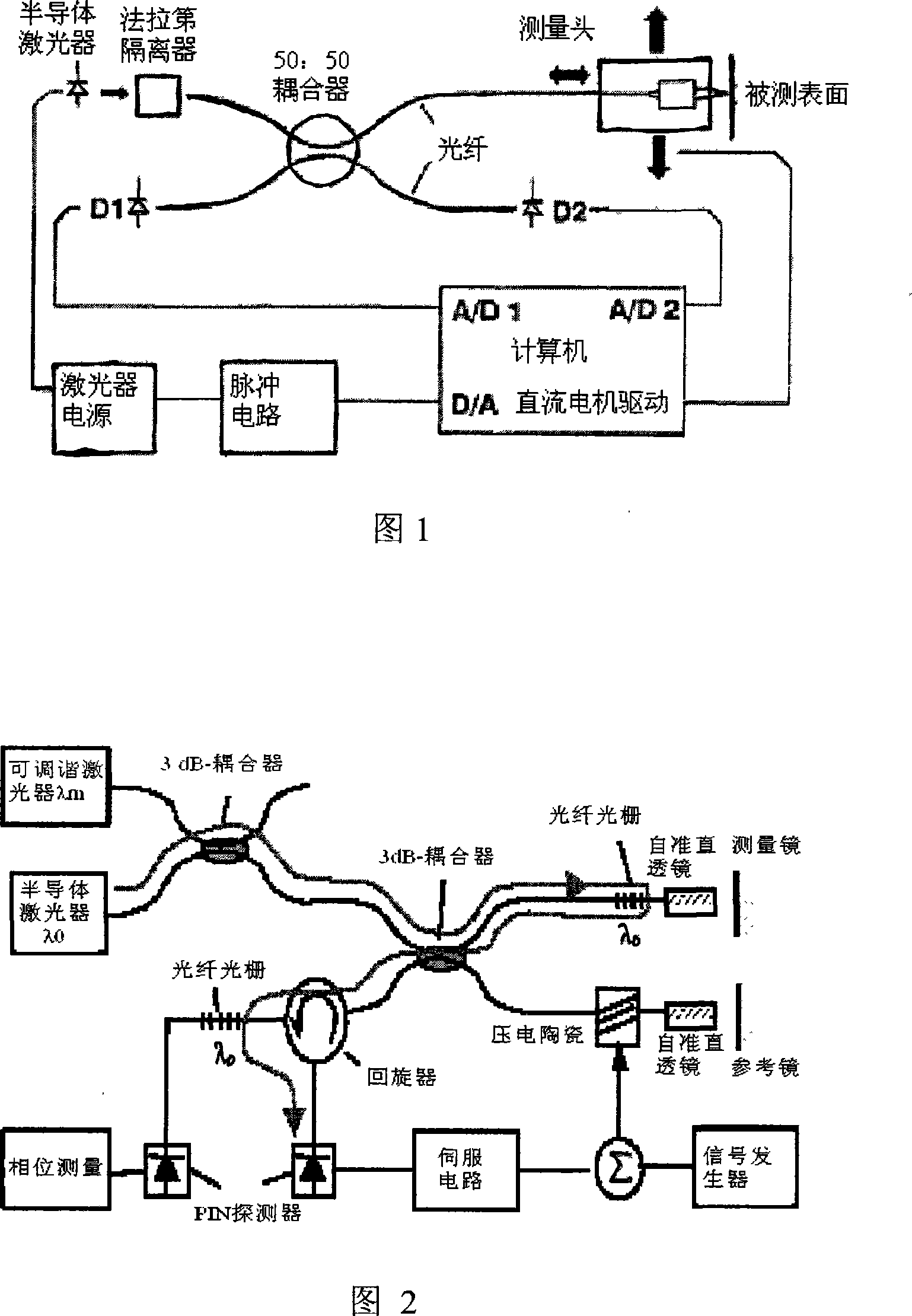

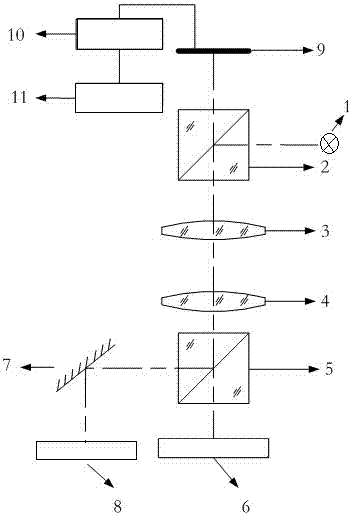

Three-dimensional on-line measuring method and system using synthesis wave to interfere whole-field nano surface

InactiveCN101109619AFast measurementSimple system structureUsing optical meansOptical elementsDashFull field

The invention provides a nanometer surface 3D on-line measuring method by using composed wave to interfere the whole field and a system for the method. The measuring range is depending upon the composed wavelength and co-path interference structure. The grating scatters the light beam of spectrum width 40 nm into two segment light pieces with wavelengths continuously and evenly distributed in the space, which are collimated into two parallel light pieces that are staggered in cross direction and are partially overlapped; the overlapped part forms the composed wave. The beam of the parallel light pieces of the composed wave is expanded by two co-focus plane cylinder lens, then through a parallel glass plate, one surface of which is coated with a semi-permeable and half-reflecting membrane, half light intensity is reflected as reference light, another half light intensity is reflected by different measured points, and is detected by a planar array CCD after being interfered by the reference light. Once the phase change of the interference signal for each pixel of CCD is measured, the longitudinal change of the measured point is got. 3D measurements for the surface is completed in one positioning. The measurement is of high speed and low cost. The measuring range is 600 swung dash 1000 Mu m, the resolution is better than 5 nm, is applicable for 3D measuring for nanometer surfaces with bosses and deep slots.

Owner:BEIJING JIAOTONG UNIV

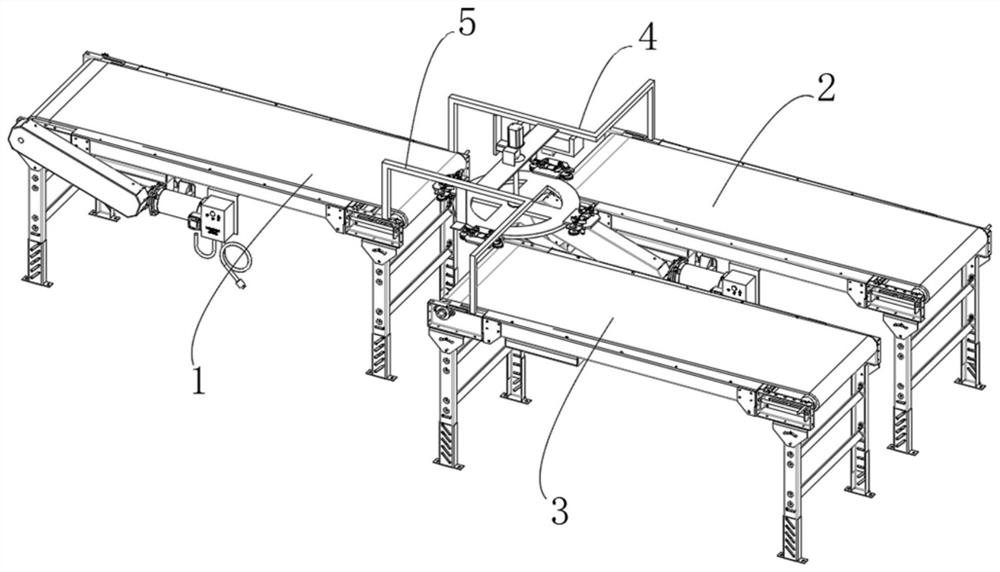

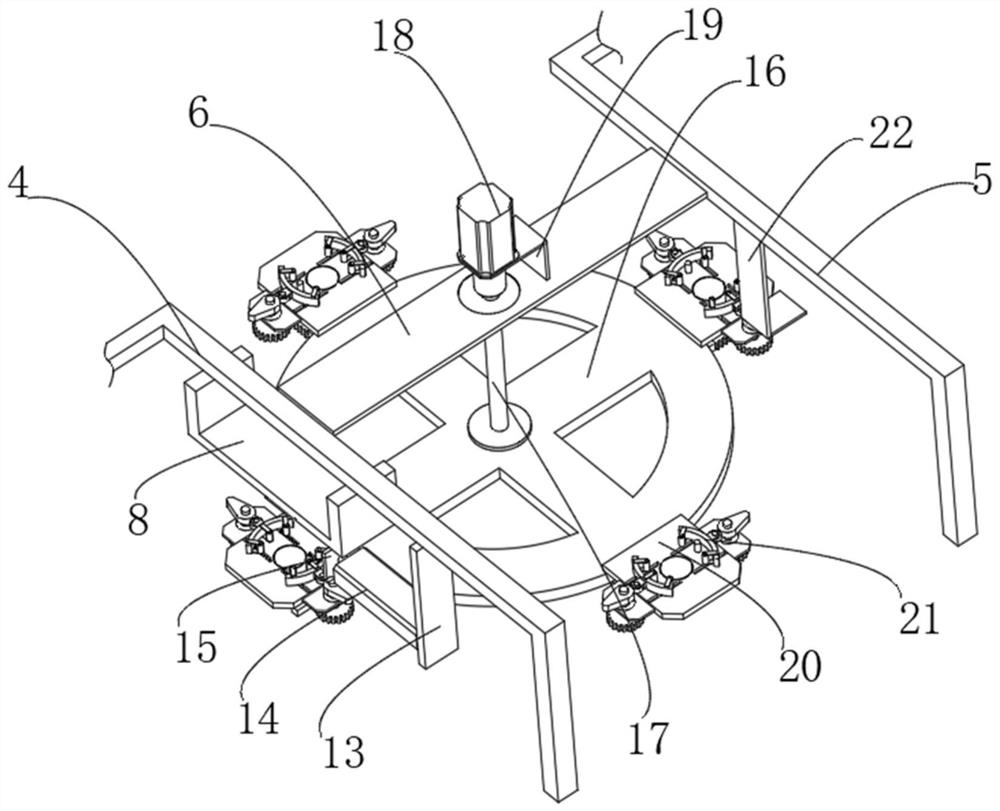

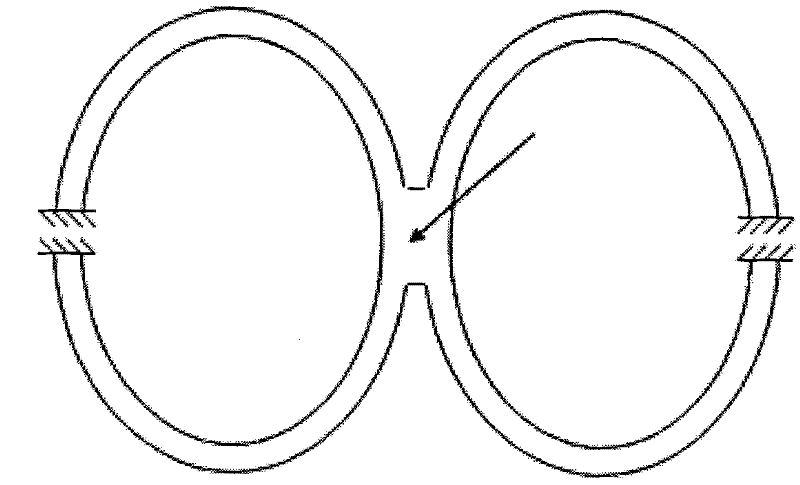

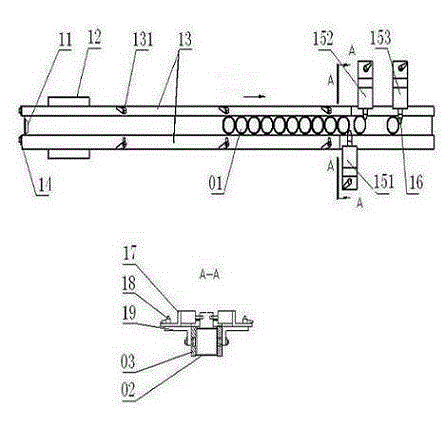

Inner and outer diameter measuring device for bearing quality detection

PendingCN114226272AImprove measurement efficiencySuitable for online measurementSortingCircular discMeasurement device

An internal and external diameter measuring device for bearing quality detection disclosed by the present invention comprises a first conveyor belt, a second conveyor belt and a third conveyor belt, the second conveyor belt and the third conveyor belt are symmetrically distributed, the first conveyor belt is located at a position close to the input end of the second conveyor belt, and a first support is fixed between the tops of the first conveyor belt and the second conveyor belt. According to the device, the three sections of conveying belts are designed, the inner and outer diameter online measuring instrument and the disc feeding mechanism are designed among the conveying belts, the disc feeding mechanism automatically conveys a clamped bearing to be measured to the position below the inner and outer diameter online measuring instrument, and whether the bearing is qualified or not is automatically measured through the instrument; after measurement, defective products and qualified products are classified, the automation degree is high, the bearing measurement efficiency is greatly improved, time and labor are saved, and the device is suitable for online measurement of batch bearings.

Owner:NINGBO PARAGON BEARING

A 3D online surface interferometry system with super lateral resolution based on spectral dispersion full field

ActiveCN105333816BFast measurementAccurate traceabilityUsing optical meansInterference fitData acquisition

The invention discloses a three-dimensional on-line interferometric measurement system for a surface with super lateral resolution based on spectral dispersion full field, belonging to the field of optical measurement. The system consists of broadband light source, isolator, optical fiber and optical fiber connector, spherical and cylindrical lens, beam splitter, rectangular prism, aperture, grating, reflector, area detector, photodetector, Fabry-Perot Filter, piezoelectric ceramics, signal processing, feedback control, data acquisition card, computer, translation stage and translation stage drive, result output, etc. The grating disperses the broadband spectrum into a light sheet with continuous distribution of wavelengths in the transverse direction, and the expanded beam is vertically incident on the surface to be measured for full-field measurement; two wavelengths are used to measure steps with a height difference greater than half the wavelength and grooves with a large aspect ratio Surface; Fabry-Perot filter is used to achieve super lateral resolution measurement; feedback control compensates environmental interference to make the system suitable for online measurement, and the measurement results are accurately traceable to the wavelength reference, and are not affected by the spectral drift of the light source.

Owner:BEIJING JIAOTONG UNIV

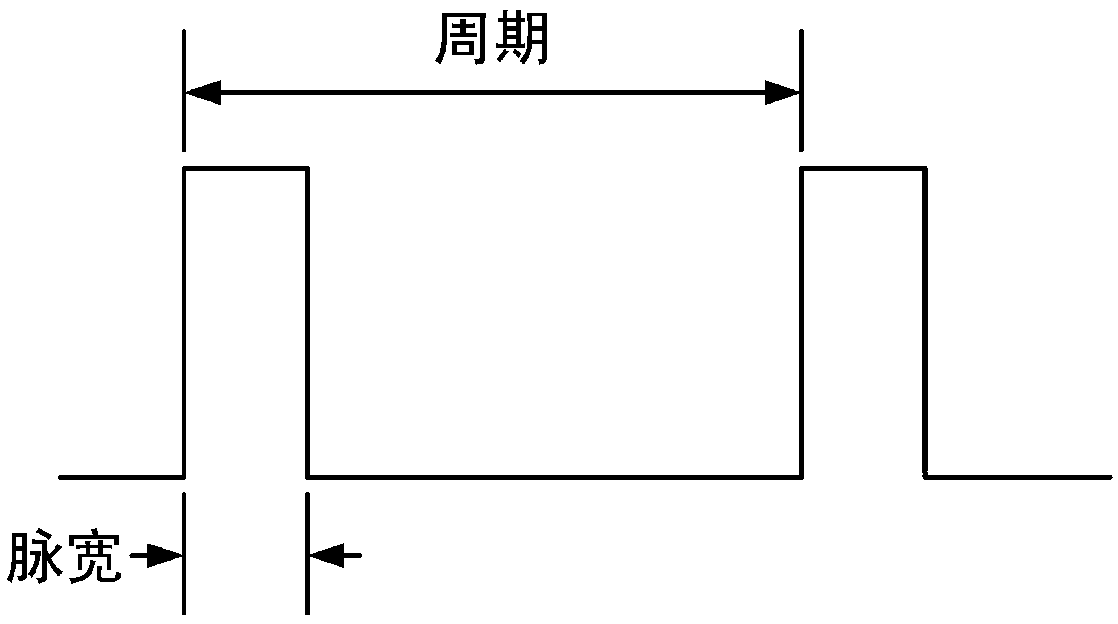

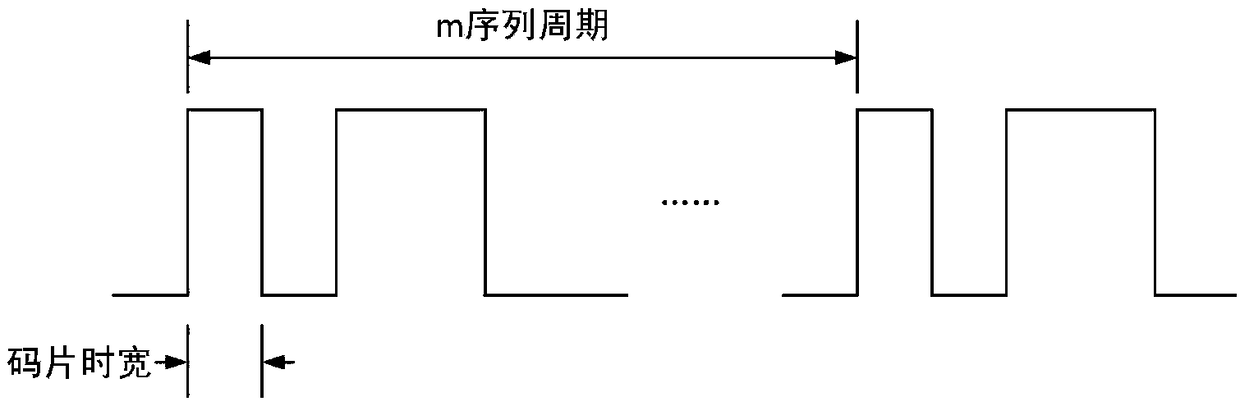

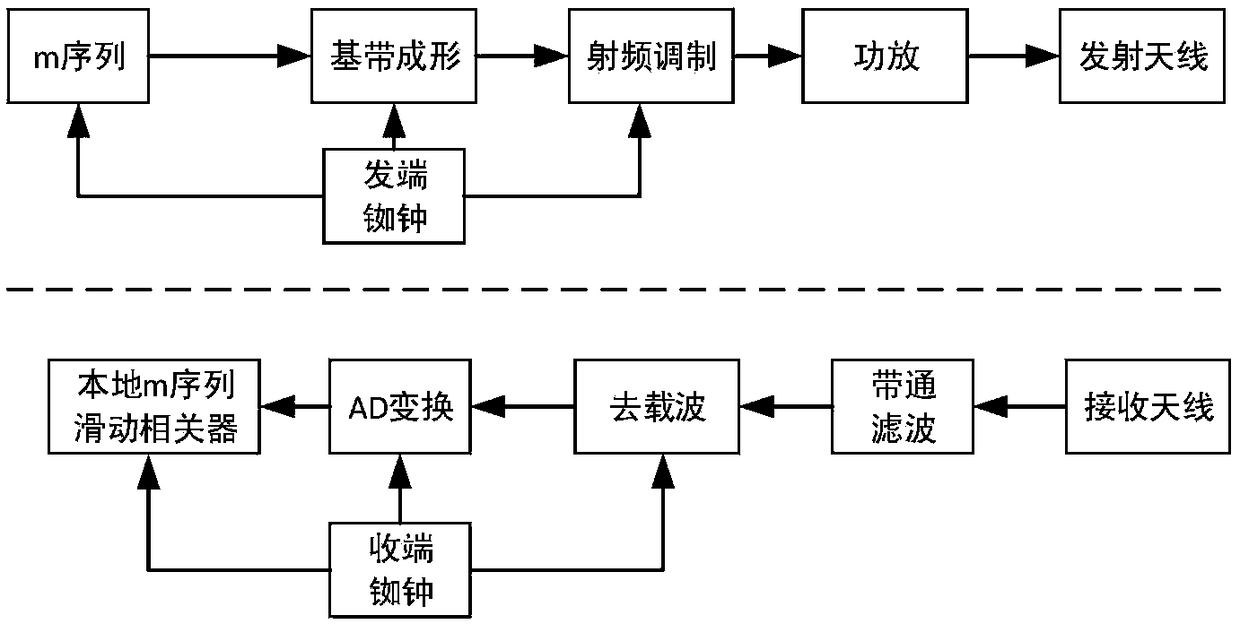

Signal waveform processing method for wireless channel parameter measurement

InactiveCN109309537ASuitable for online measurementSimple design methodTransmission monitoringChannel parameterMeasurement precision

The invention belongs to the technical field of wireless channel measurement and discloses a signal waveform processing method for wireless channel parameter measurement signals. A pulse signal and apseudorandom sequence are combined. A pulse random sequence signal is taken as a signal basic waveform. Framing and sending are carried out according to pulse per second timing information. At a receiving end, synchronous sliding correlation reception is carried out through utilization of second timing information. On the premise that delay measurement precision is not reduced, clock synchronization of a transmitter and a receiver is avoided before measurement each time, measurement delay precision and the maximum measurable delay in different scenes can be freely adjusted, the pseudorandom sequence does not need to be reelected, and the method is relatively applicable to online measurement. The method has the advantages that on the premise that the delay measurement precision is not reduced, the clock synchronization of the transmitter and the receiver is avoided before each time measurement, the measurement delay precision and the maximum measurable delay in different scenes can be freely adjusted, the pseudorandom sequence does not need to be reelected, and the method is applicable to the online measurement.

Owner:STATE KEY LAB OF COMPLEX ELECTROMAGNETIC ENVIRONMENTAL EFFECTS ON ELECTRONICS & INFORMATION SYST

Online measuring method of self clean glass contact angle

ActiveCN100533057CEasy to verify uniformityEasy to identifyUsing optical meansMaterial testing goodsEngineeringSelf-cleaning glass

The invention provides an on-line measurement method for the contact angle of self-cleaning glass, which adopts the actual use conditions closer to the self-cleaning glass film layer as the test condition, adopts the pendant drop method to test and the θ / 2 method to calculate, and can quickly and accurately measure on-line The contact angle of self-cleaning glass and related film layers, and can measure the contact angle of small angle more accurately.

Owner:FUYAO GLASS IND GROUP CO LTD

Synthetic wave interference nano surface tri-dimensional on-line measuring system and method

InactiveCN100491901CFast measurementLow costUsing optical meansOptical elementsSpectral widthGrating

The invention relates to a nano-surface interference 3D online measurement system with composite wave and the method thereof. The range depends on the wavelength of the composite wave, and the system has a common path interference structure. The beam with spectral width of 40 nm is color dispersed into two sectored lights with wavelength continuously and uniformly distributed in space by utilizing the double dispersion property of a dual-period grating, the two sectored lights are collimated to two parallel lights with transverse misplacement and partial overlapping, and the overlapped part forms a composite wave. The parallel lights of the composite wave passes through a plano-convex focusing lens with a cylindrical surface coated with a semi-transmitting and reflective film, then one half of the lights are reflected to become reference light and the other half of the lights are focused to become light, and then the light is reflected by different measuring points, interfered with the reference light and detected by an array CCD. If the phase variation of the interference signal of each pixel of CCD is measured, then the longitudinal variation at the measuring point can be obtained. The nano-surface 2D measurement is finished by once location; and the nano-surface 3D measurement is finished by transverse scanning of light. The measurement range is 600-1,000 micron, and the resolution is higher than 5 nm. The invention has the advantages of high measurement speed, and low cost; and is suitable for measurement of nano-surface with boss and deep groove.

Owner:BEIJING JIAOTONG UNIV

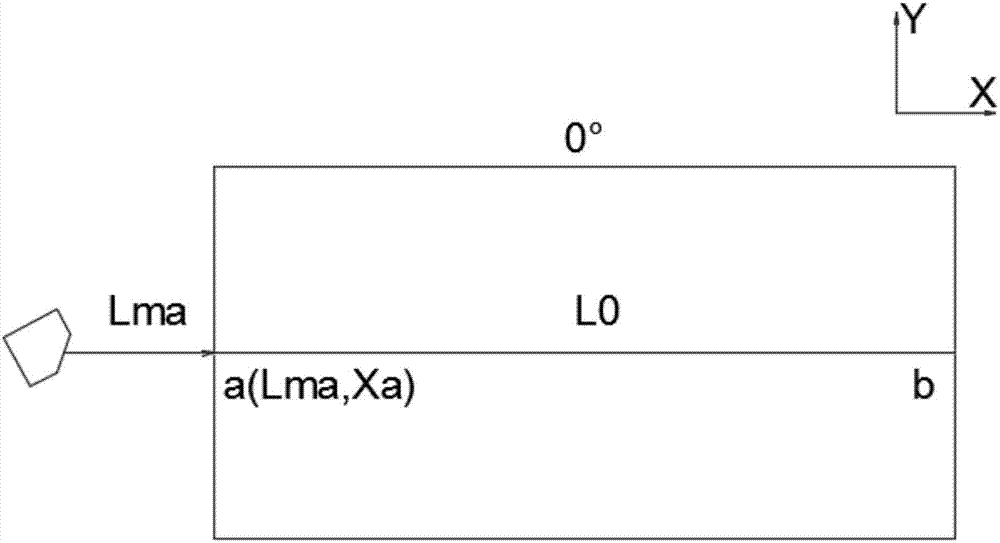

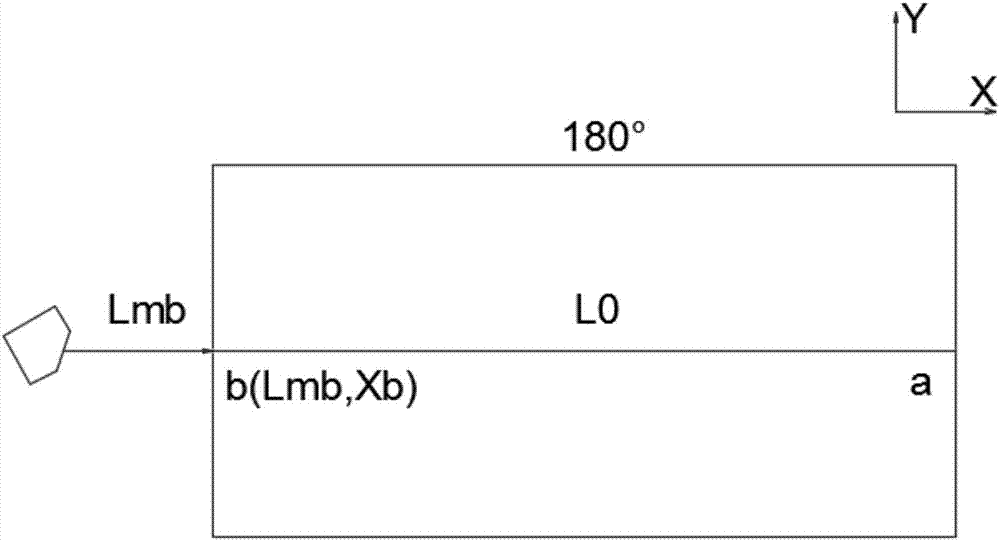

Length comparison difference value measurement method without accurate positioning

PendingCN107339940AAccurate measurementQuick measurementUsing optical meansLaser sensorMeasurement precision

The invention discloses a length comparison difference value measurement method without accurate positioning. The length comparison difference value measurement method without accurate positioning comprises steps of determining a standard workpiece, wherein the length of the workpiece is L0, also known as Lab, making a measurement reference plane perpendicular to a measured reference plane, making a laser sensor measure to an a point, obtaining reference data a point (Lma,Xa), rotating the standard workpiece for 180 degrees, making the laser sensor measure to b point (Lmb,Xb), using the above method to establish a relation between the standard workpiece, the length of which is L0, and the a point (Lma,Xa) and b point (Lmb,Xb), using the measurement method to measure data of two points a1, b1 that a workpiece having an unknown length chooses, obtaining data of the a1 point (Lma1,Xa1) and the b1 point (Lmb1,Xb1) through measurement, calculating a length of the workpiece through a following formula: a practical workpiece length La1b1=(Xa1-Xa)+(Lma1-Lma)+(Xb1-Xb)+(Lmb1-Lmb)+Lab. The length comparison difference value measurement method without accurate positioning uses a comparison difference value to calculate, reduces measurement conditions, improves measurement accuracy and improves a measurement speed.

Owner:浙江机电职业技术学院

Three-dimensional on-line measuring method and system using synthesis wave to interfere whole-field nano surface

InactiveCN100455987CFast measurementSimple structureUsing optical meansOptical elementsGratingWide beam

The invention discloses a nanometer surface 3D on-line measuring method by using composed wave to interfere the whole field and a system for the method. The measuring range is depending upon the composed wavelength and co-path interference structure. The double color scattering property of the double-period grating scatters the light beam of spectrum width 40 nm into two segment light pieces with wavelengths continuously and evenly distributed in the space, which are collimated into two parallel light pieces that are staggered in cross direction and are partially overlapped; the overlapped part forms the composed wave. The beam of the parallel light pieces of the composed wave is expanded by two co-focus plane cylinder lens, then through a parallel glass plate, one surface of which is coated with a semi-permeable and half-reflecting membrane, half light intensity is reflected as reference light, another half light intensity is reflected by different measured points, and is detected by a planar array CCD after being interfered by the reference light. Once the phase change of the interference signal for each pixel of CCD is measured, the longitudinal change of the measured point is got. 3D measurements for the surface is completed in one positioning. The measurement is of high speed and low cost. The measuring range is 600 swung dash 1000 Mu m, the resolution is better than 5 nm, is applicable for measuring nanometer surfaces with bosses and deep slots.

Owner:BEIJING JIAOTONG UNIV

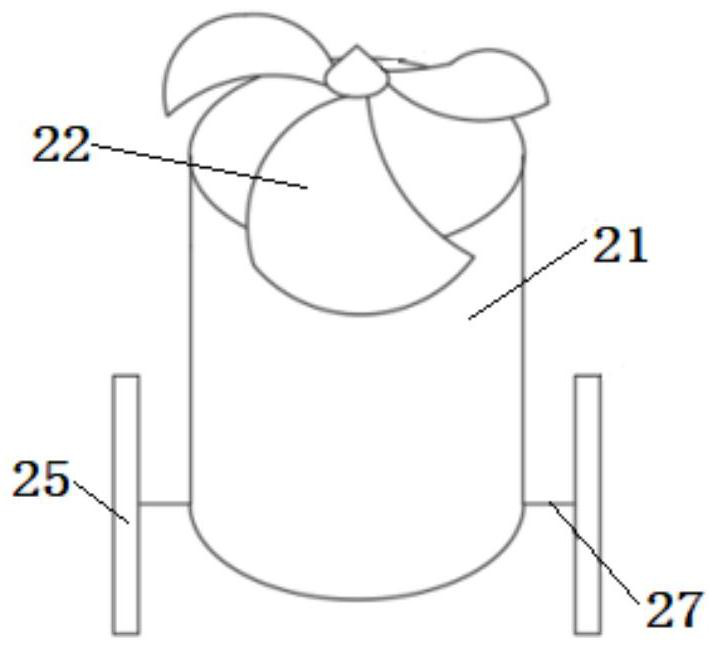

Flue gas flow velocity measuring device

PendingCN113917182AReal-time adjustment of measurement pointsAvoid easy cloggingFluid speed measurementThermodynamicsFlue gas

The invention relates to a flue gas flow velocity measuring device which comprises a bracket; a flow velocity conversion part which is used for acquiring a flue gas flow velocity signal and converting the flue gas flow velocity signal into an electric signal and is movably arranged on the bracket; a power conversion part which receives the electric signal and converts the electric signal into a power signal, and is electrically connected with the flow rate conversion part; a central control part which is used for receiving the power signal and calculating the flow velocity of the flue gas, and is electrically connected with the power conversion part; and a moving assembly which drives the flow velocity conversion part to move on the bracket and is connected with the flow velocity conversion part. According to the invention, continuous multi-point measurement in one direction can be realized, measurement point positions can be adjusted in real time, flue gas flow velocity can be recorded in real time, flue gas flow velocity distribution in the direction can be obtained, the problem of poor representativeness of existing online flue gas flow velocity measurement can be effectively solved, and the problem of easy ash clogging in an existing device can be avoided through conversion of a signal transmission mode. The structure is novel, the operation is simple, the production is easy, and the production and maintenance cost is saved.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

Device and method for measuring laser wavelength

ActiveCN111289124BHierarchical imaging facilitatesCompact structureOptical measurementsPhotomechanical apparatusLight beamInterferometric imaging

The invention discloses a laser wavelength measurement device and method. The laser wavelength measurement device includes: a first optical path assembly and a second optical path assembly; and the second optical path assembly and the first optical path assembly form a laser wavelength measurement optical path, wherein the second The optical path assembly includes: an FP etalon assembly and an optical classifier, the homogenized laser beam passes through the FP etalon assembly to generate interference fringes; and the optical classifier is arranged behind the FP etalon assembly in the laser wavelength measurement optical path, It is used to deflect the laser beam passing through the FP etalon assembly. The FP etalon assembly of the present invention enables two FP etalons to share the same optical path for interference imaging, has a compact structure, small volume, simple design, and high stability; with the cooperation of an optical classifier, accurate measurement of the laser wavelength can be realized at the same time, The wavelength measurement range is large, suitable for online measurement of laser wavelength and corresponding closed-loop control feedback.

Owner:RAINBOW SOURCE LASER RSLASER

A device and method for measuring coaxiality

ActiveCN104776816BHigh measurement accuracyThe effect of the surface shape of the objectUsing optical meansElectricityGrism

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

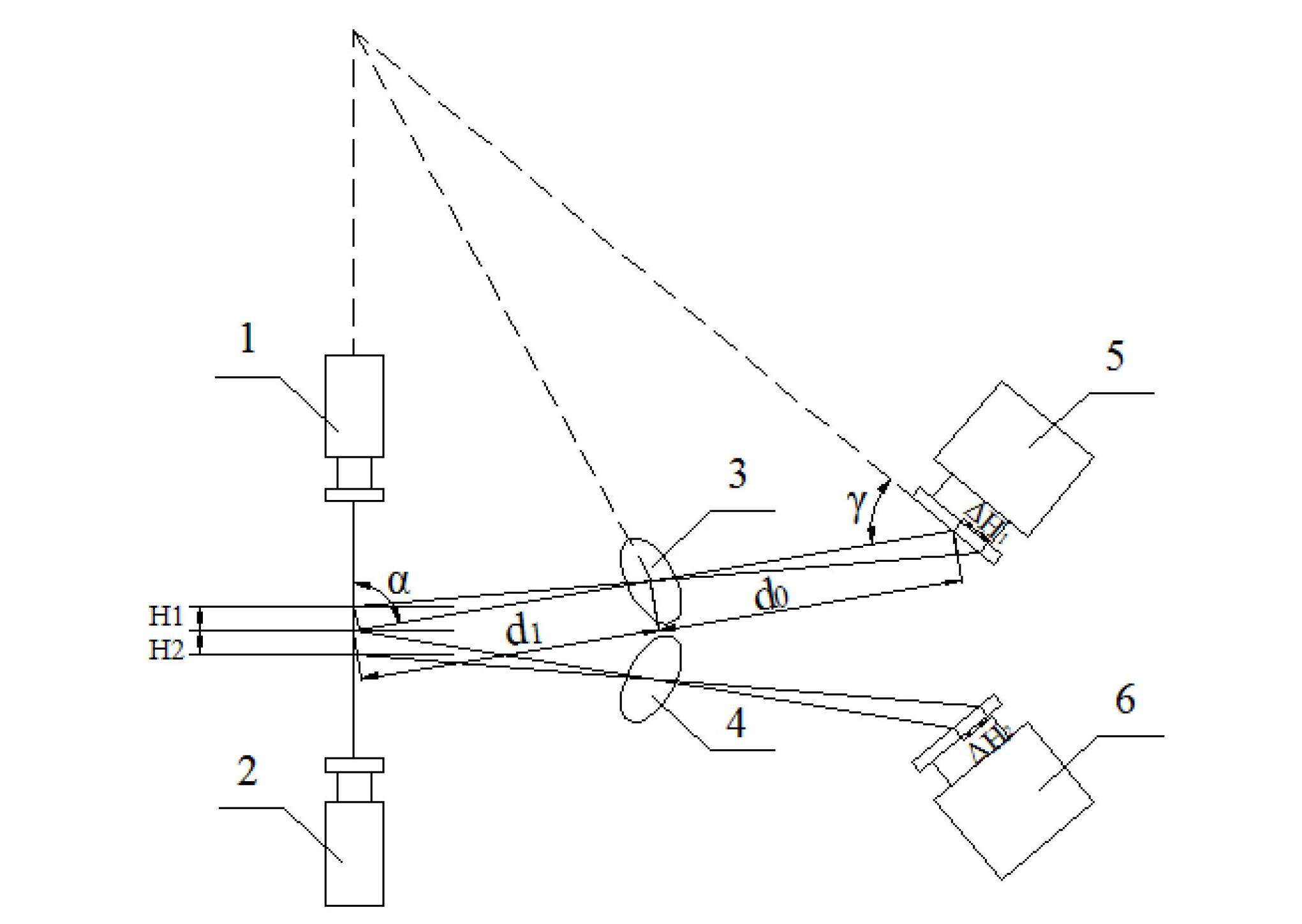

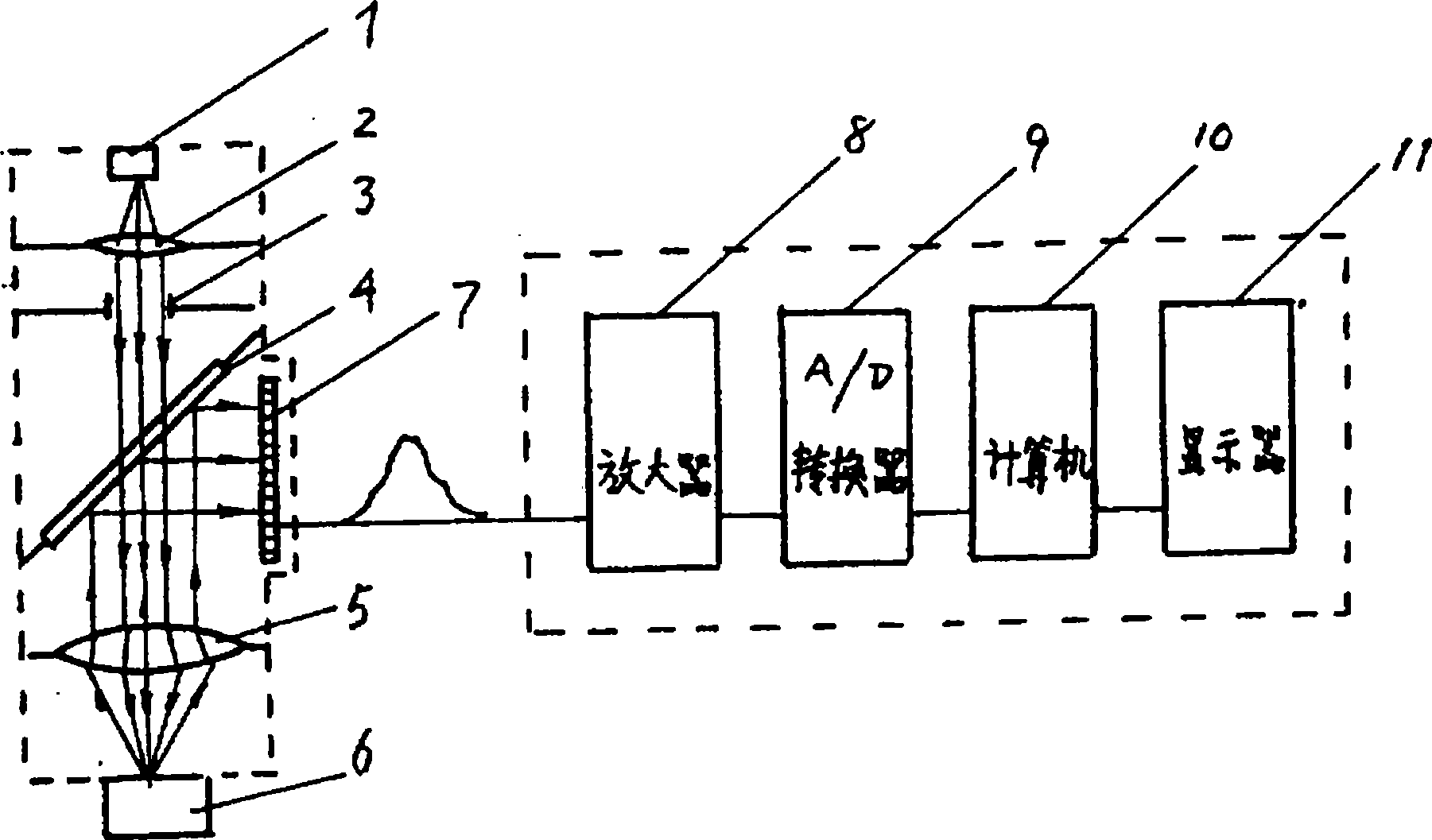

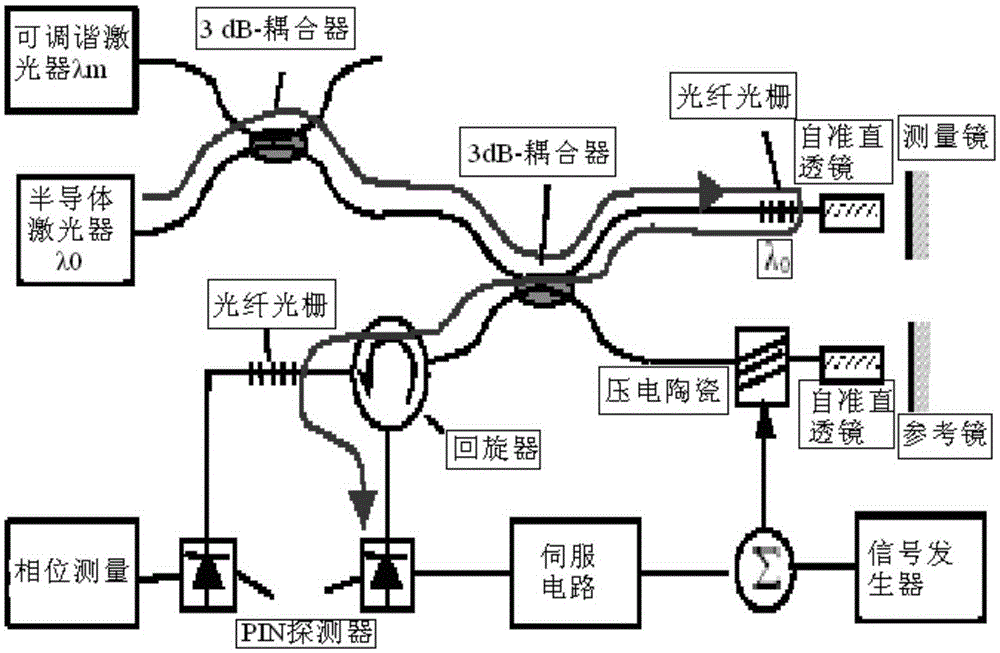

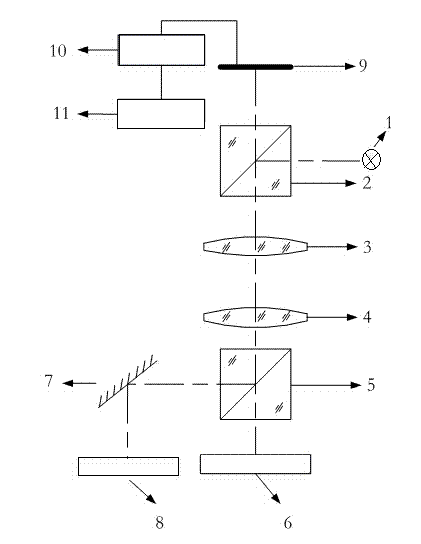

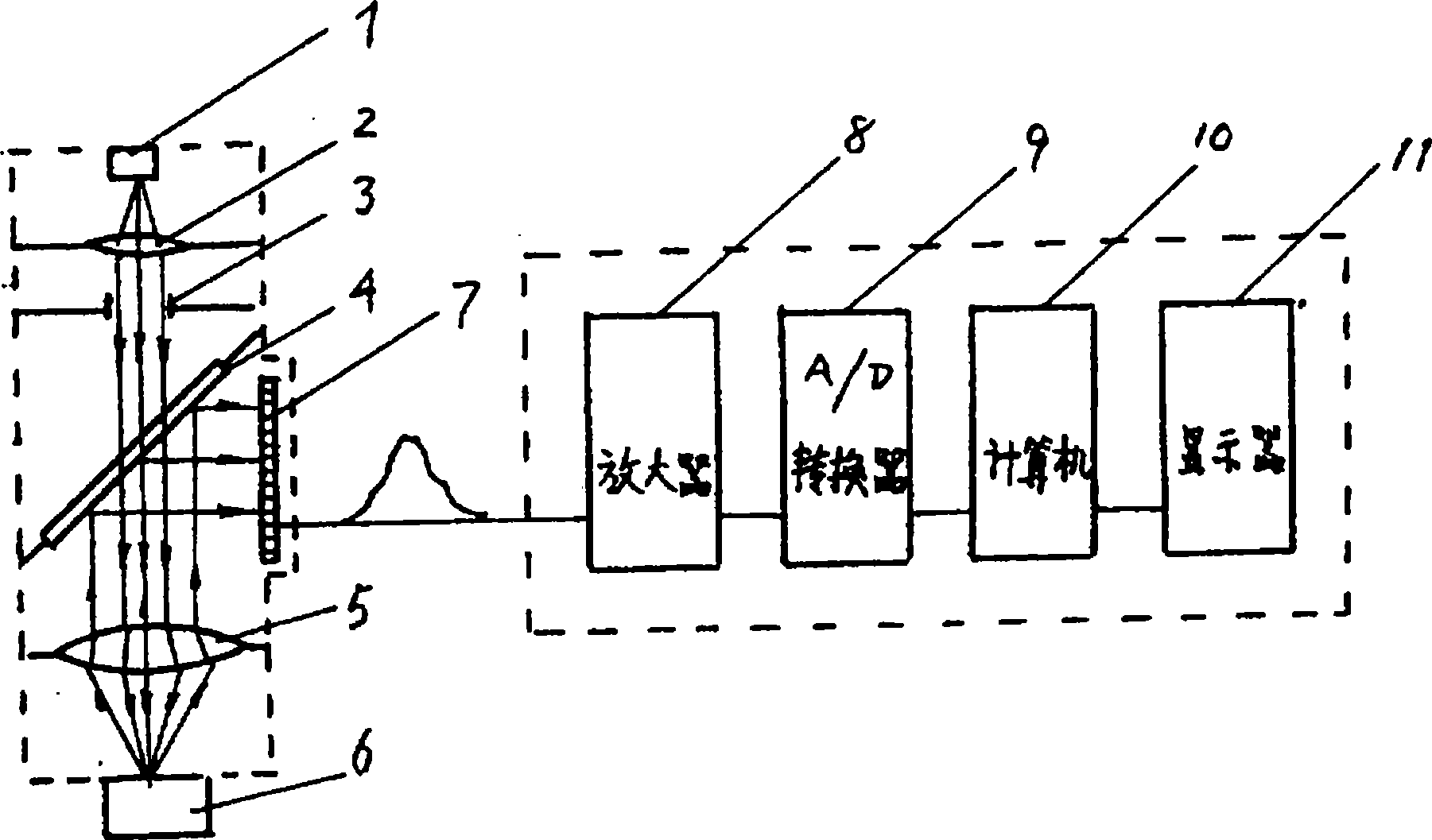

Beam-scanning interference type nano surface tri-dimensional on-line measuring system and method

Interference type nano-surface three-dimensional online measurement system and method using light beam scanning with common path interference structure can suppress environmental disturbance, including a grating for dispersing a light beam with a spectrum of 40nm to the light with spatial continuous distributed wavelength which is collimated to be parallel light by a plane-cylinder lens coated with semitransparent half-reflective film, therefore a half of light is reflected back as reference light, while another part is focused to light beam with different wavelengths reflected back to the system by different detected points and then dispersed to the light with spatial continuous distributed wavelength after interference with the reference light, so as to be detected by linear CCD. Different pixel of the CCD detect interference signal with different wavelength, and obtain interference signal phase change of each pixel, namely obtain longitudinal value change of corresponding detected point. The two-dimensional surface measurement can be realized by one location, and the three-dimensional surface measurement can be realized by light horizontal scanning, thereby improving greatly the measurement speed, reducing costs, extending measuring range to 300 um with resolution superior than 0.1nm using optical path tracking.

Owner:BEIJING JIAOTONG UNIV

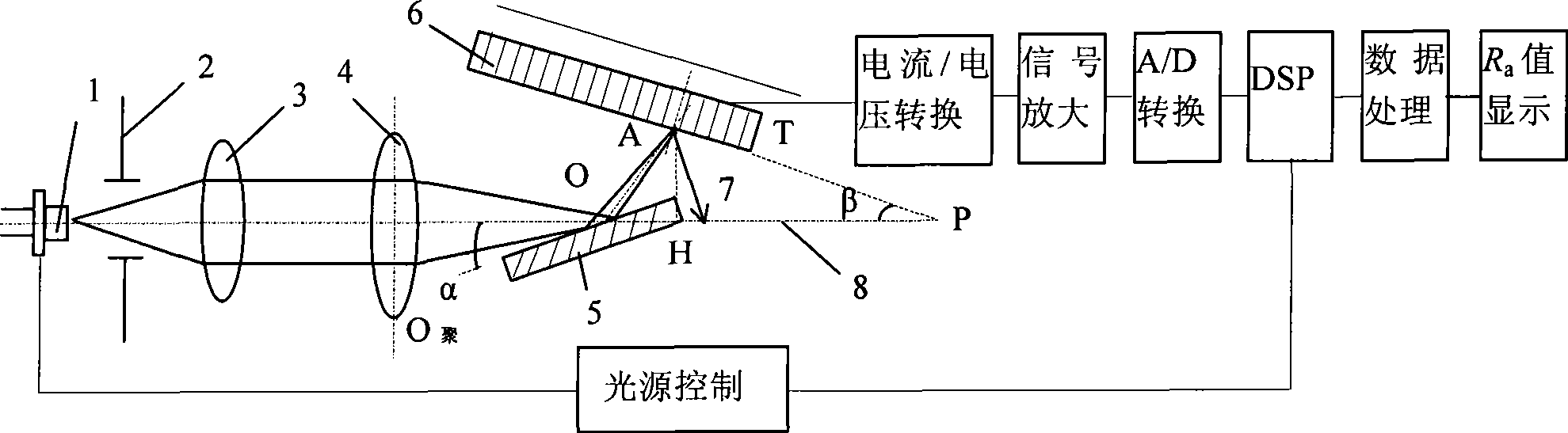

Detection device for roughness of surface

The invention provides a detection device for surface roughness, which comprises a light source unit and a photoelectric detector. Light which is emitted by the light source unit is radiated on the measured surface; the photoelectric detector detects a detection signal which is obtained by the light which is reflected by the measured surface; the measured surface, a light shaft of the detection device and the photoelectric detector are positioned in a same plane; the measured surface is arranged by forming a first angle with the light shaft; and the photoelectric detector is arranged by forming a second angle with the light shaft, thereby preventing the light from being reflected back to the measured surface from the photoelectric detector. The detection device of surface roughness can not only avoid the impacts of the reflected light on the measurement result, but can also reduce an absorption device and further reduce the costs.

Owner:北京时代之峰佳亿科技有限责任公司

A seamless table tennis bounce performance detection and sorting method

ActiveCN106500935BRealize real-time online detectionSimple structureElasticity measurementCollision detectionComputer science

Owner:TIANJIN UNIV

On-line measuring method of Poisson ratio of micro-electromechanical system (MEMS) film based on resonance frequency method

ActiveCN101769898BAvoid errorsHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesElectrical conductorFilm base

Owner:常熟紫金知识产权服务有限公司

Automatic separator for valve tappet and valve shim

InactiveCN102133573BGood repeatabilityImprove stabilitySortingControl systemProgrammable logic controller

The invention relates to an automatic separator for a valve tappet and a valve shim, which is controlled by a PLC (Programmable Logic Controller) control system. The automatic separator is characterized in that a material distributing system is arranged, a feeding system is arranged one side of one end of the material distributing system, a measuring system is arranged at the opposite side of one end of the material distributing system, and positioned behind the feeding system. A separating system is arranged behind the measuring system; the material distributing system and the separating system are respectively provided with a feeding conveyer belt and a separating conveyer belt which are arranged on the same plane; and the material distributing system, the feeding system, the measuring system and the separating system are connected into a whole. The automatic separator has higher repeatability, stability, measuring precision and measuring speed, is large in application range of a tested workpiece, can achieve the accurate and precise measurement and grouping on height of platform in the valve tappet and the valve shim, and is also suitable for on-line measurement.

Owner:邹国庆

Mechanism for rapidly measuring radial difference of outer wall of casing and its use method

ActiveCN108020137BAvoid measurement interference problemsEasy to measureMechanical measuring arrangementsEngineeringMeasurement precision

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Synthetic wave interference nano surface tri-dimensional on-line measuring system and method

InactiveCN100491902CFast measurementLow costUsing optical meansOptical elementsPhase variationGrating

Owner:BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com