On-line measuring method of Poisson ratio of micro-electromechanical system (MEMS) film based on resonance frequency method

A technology of resonance frequency and measurement method, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of complex operation, need, and inapplicability to online measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

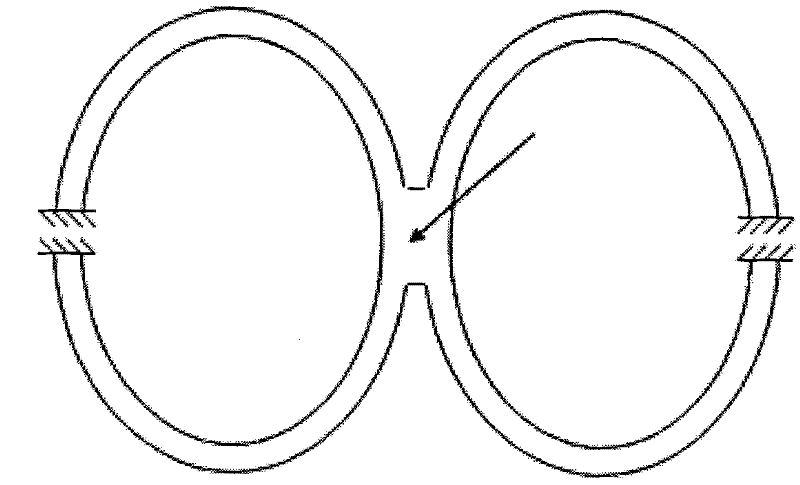

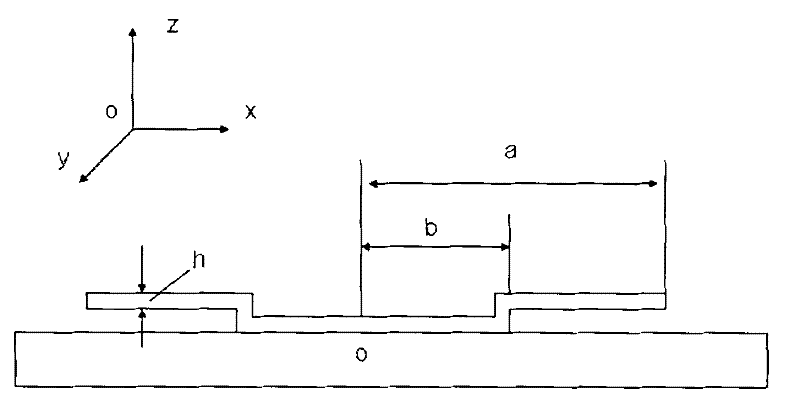

[0100] Such as( Figure 6-1 ), in the silicon sacrificial layer process, a layer of 0.3 μm thick silicon dioxide (sio 2 ) layer 2, and then deposited a layer of 0.2 μm thick silicon nitride layer 3 ( Figure 6-1 ), and then deposit a layer of phosphosilicate glass with a thickness of 2 μm as a sacrificial layer 4 ( Figure 6-2 ), after gluing, exposing and developing, etch a circular cavity 5 with a radius of 200 microns on the sacrificial layer 4 with HF solution ( Figure 6-3 ), and then deposit a layer of 2 μm thick polysilicon thin film as the structure layer 6 (6-4), on the structure layer with the anchor region as the center, etch a circular disc 7 with an outer radius of 400 μm ( Figure 6-5 ), remove the sacrificial layer with HF solution to get the desired structure ( Figure 6-6 ). Use the MSA-500 microscopic laser vibrometer to measure the resonant frequency f of radial vibration 1 = 1.0650E07 Hz and the resonant frequency f of the transverse vibration 2 = 6.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com