Automatic separator for valve tappet and valve shim

A technology for automatic sorting and shims, applied in the field of valve shims automatic measurement, automatic sorting instrument, and valve tappet, which can solve the problems affecting engine power and emissions, poor reliability, and low efficiency, and achieve high repeatability. The effect of a wide range of properties and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] PLC program control system control components are:

[0035] ⑴The material distribution system 1 has three material distribution cylinders and one conveying motor.

[0036] ⑵The feeding system 2 has a manipulator (composed of two moving cylinders).

[0037] (3) Measuring system 3 has a measuring cylinder and a grating length meter.

[0038] ⑷Sorting system 4 has twelve sorting cylinders and a conveying motor with brake.

[0039] The control components of the PLC program control system also have 21 solenoid valves, 20 magnetic switches and a pressure switch.

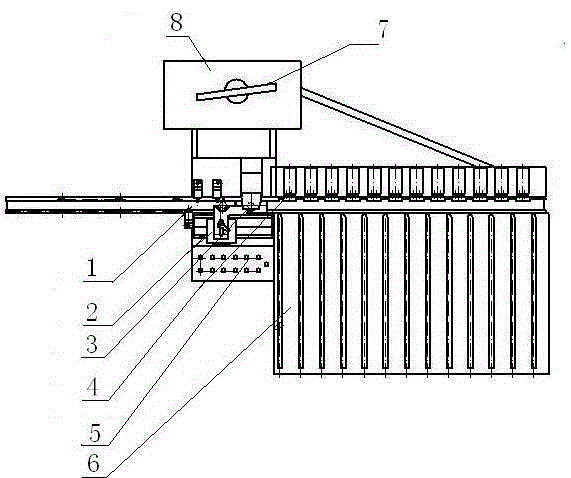

[0040] figure 1 for the overall schematic.

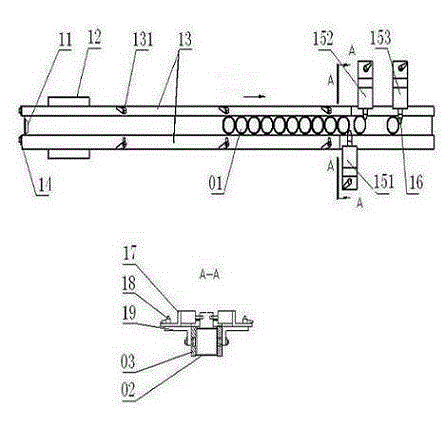

[0041] The structure of distribution system 1 is as follows: figure 2 As shown, the feeding conveyor belt 02 is installed on the conveying roller 11, and the conveying roller is installed on the conveying frame 03, and the conveying roller is driven by a continuously working conveying motor 12, and the feeding conveyor belt 02 is continuously working. Adjust the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com