Three-dimensional on-line measuring method and system using synthesis wave to interfere whole-field nano surface

A measurement method and measurement system technology, applied in the field of optical measurement, can solve the problems of complex scanning mechanism, high instrument cost, slow measurement speed, etc., and achieve the effects of simple system structure, high measurement accuracy, and fast measurement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

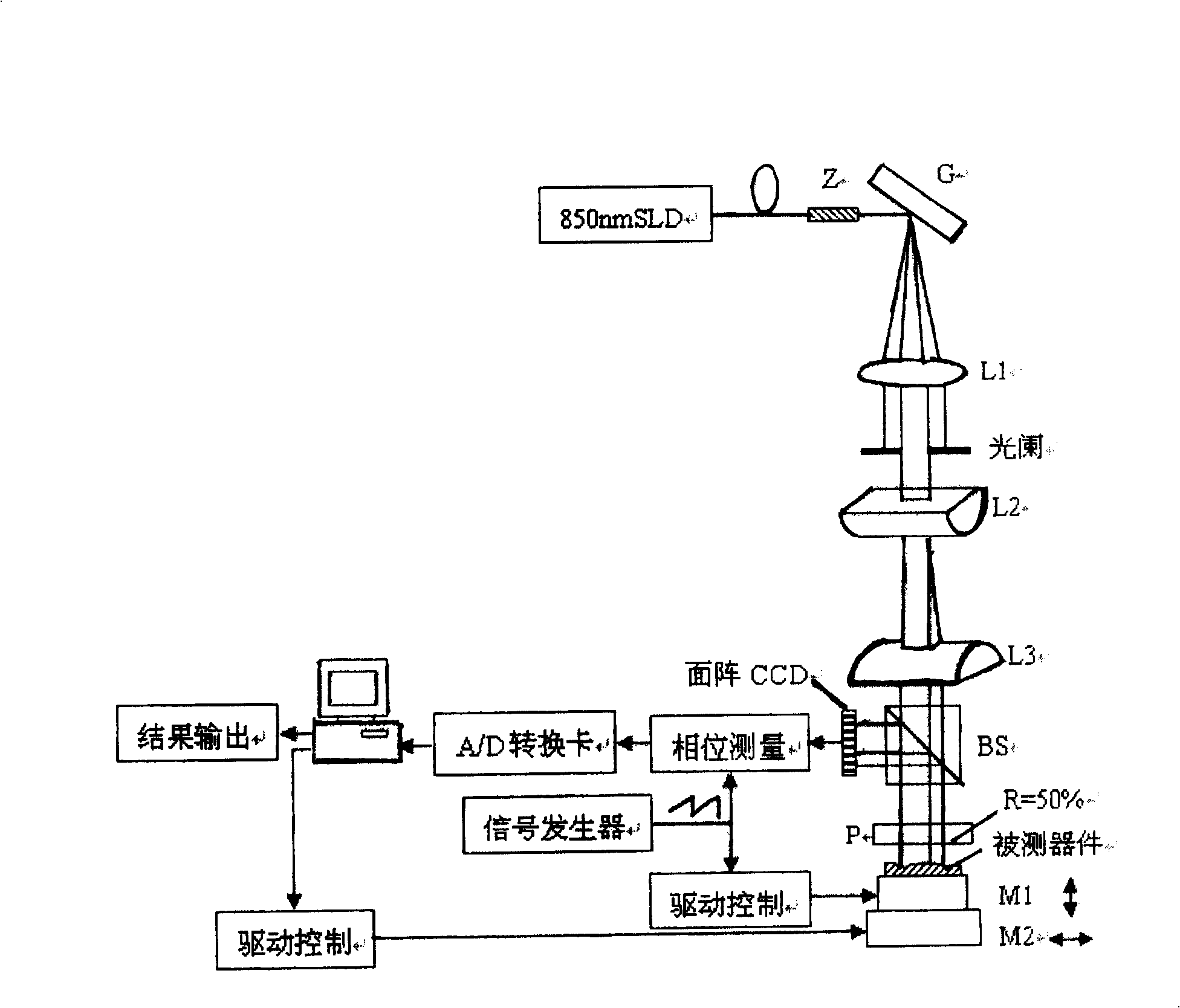

[0025] Such as image 3 As shown, the light with a spectral width of 40nm emitted by a superluminescent diode SLD with a central wavelength of 850nm is collimated into a parallel beam after passing through the fiber self-collimating lens Z. Uniformly distributed fan-shaped light sheets, the two fan-shaped light sheets are collimated by the collimator lens L1 to become parallel light sheets with continuous and uniform distribution of wavelengths in space, these two parallel light sheets are parallel to each other, laterally displaced, and partially overlapped in space. The wavelength λ of the two parallel light sheets corresponding to different points in the transverse direction of the overlapping part of the two parallel light sheets 1 and lambda 2 Different, these two different wavelengths meet to form a composite wave, and the composite wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com