Centrifugal clutch assembly integrated structure and automatic speed change hub with large speed change ratio

A technology of centrifugal clutch and automatic transmission, which is applied in the direction of vehicle gearboxes, vehicle components, wheel transmissions, etc., can solve problems such as the need to improve the riding experience, affect reliability, and complex assembly, so as to optimize the riding experience and prolong the life of the vehicle. Effects of service life, reduced number of parts and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

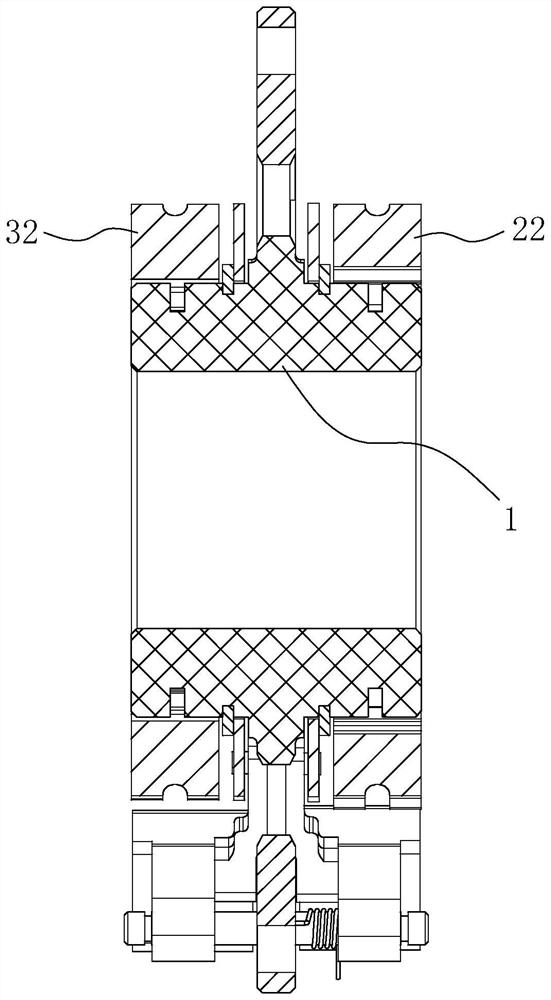

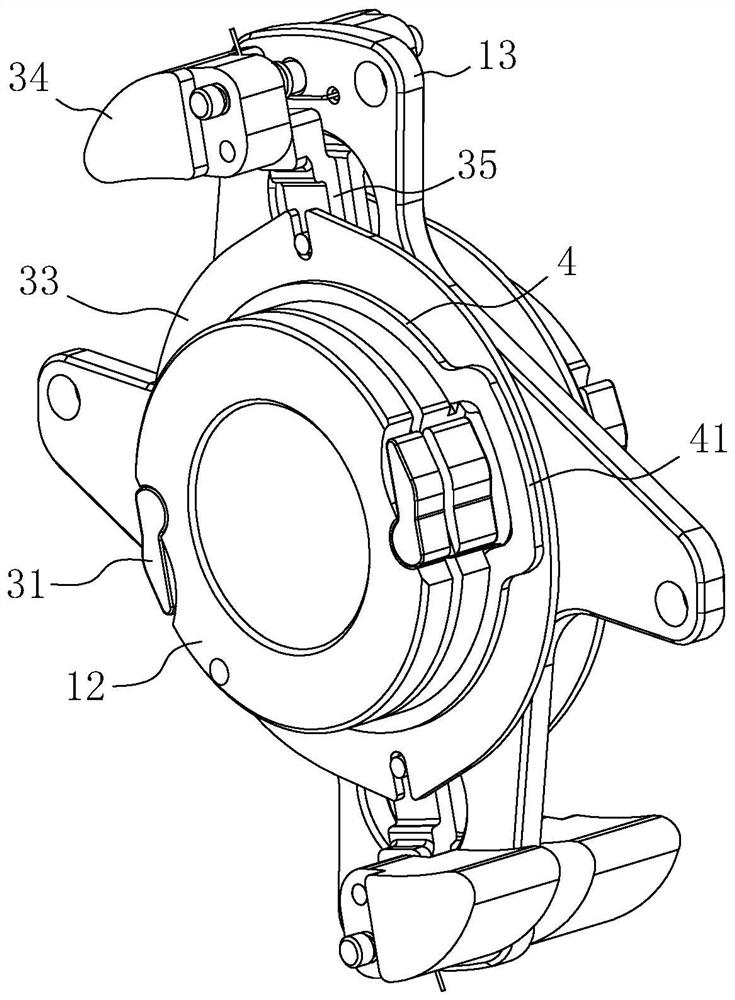

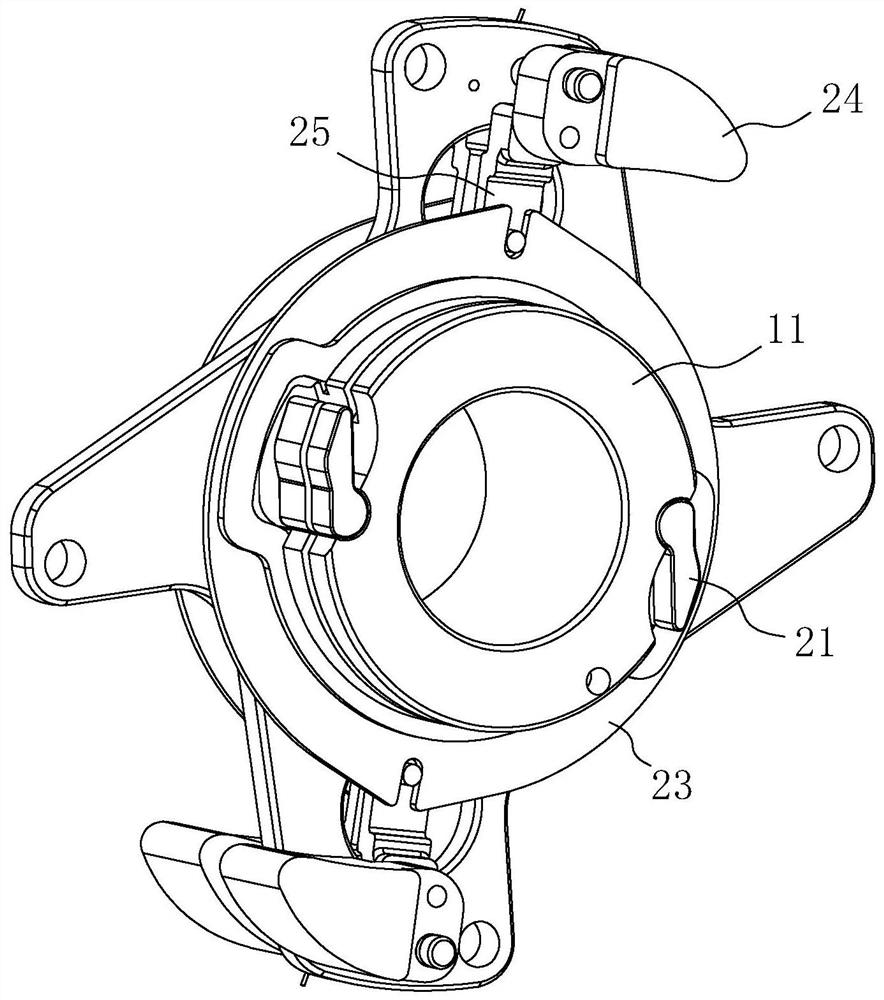

[0040] An integrated structure of centrifugal clutch components, refer to Figure 1 to Figure 3 , which includes the first clutch inner ring part 11, the first clutch driver 21 and the first buffer frame 22, and the second clutch inner ring part 12, the second clutch driver 31 and the second buffer frame 32; the first clutch inner The ring part 11 and the second clutch inner ring part 12 are fixedly connected or integrally formed to form an integrated inner ring 1; preferably, in this embodiment, the integrated inner ring 1 is integrally formed, so that the number of parts and the assembly process can be reduced, and the production cost and detection cost, and can improve the reliability and stability of the work, and can also simplify the structure and optimize the size, such as reducing the axial size; of course, in other optional embodiments, the first clutch inner ring part 11 and the second clutch inner ring part 12 can also be fixedly connected as a whole by means of wel...

Embodiment 2

[0044] An automatic transmission hub with a large transmission ratio, refer to Figure 1 to Figure 5 , including a hub tube 8, the hub tube 8 is respectively provided with the first planetary gear assembly, the second planetary gear assembly and the integrated structure of the centrifugal clutch assembly in Embodiment 1, and the integrated structure of the centrifugal clutch assembly is located between the first planetary gear assembly and the second planetary gear assembly Between the two planetary gear assemblies; the fixing plate 13 is pierced with fasteners connected to the inner end surface of the hub tube 8; in this embodiment, two sets of planetary gear assemblies are set to form three gears, and according to the speed of the power output unit To realize the automatic switching of the three gears, which can further improve the riding experience.

[0045] refer to Figure 1 to Figure 5 Specifically, in this embodiment, the first planetary gear assembly includes a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com