Material replacement anti-corrosion system for nuclear science

An anti-corrosion and nuclear science technology, applied in containers, packaging, workpiece clamping devices, etc., can solve the problems of inconvenient replacement of the inner lining of the storage tank, affecting the replenishment of anti-corrosion coatings, and unfavorable material storage, so as to avoid coating failure. , Easy to replace, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

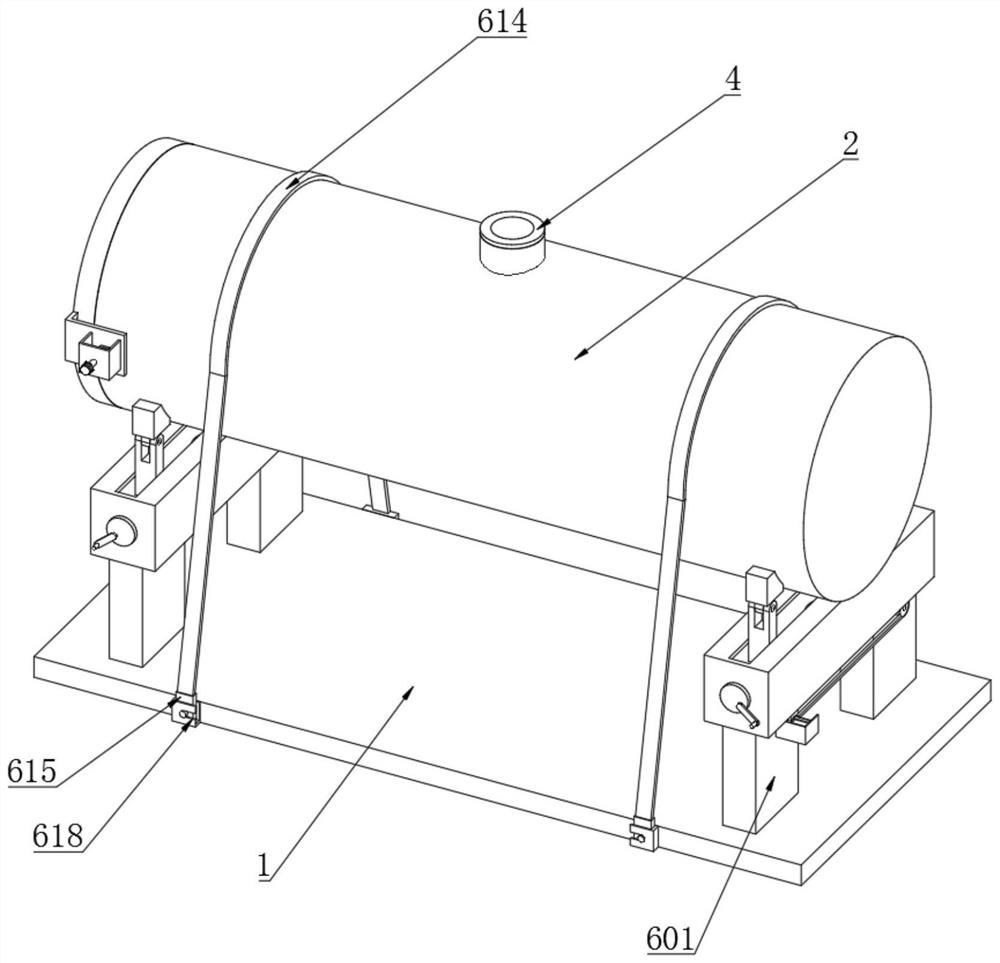

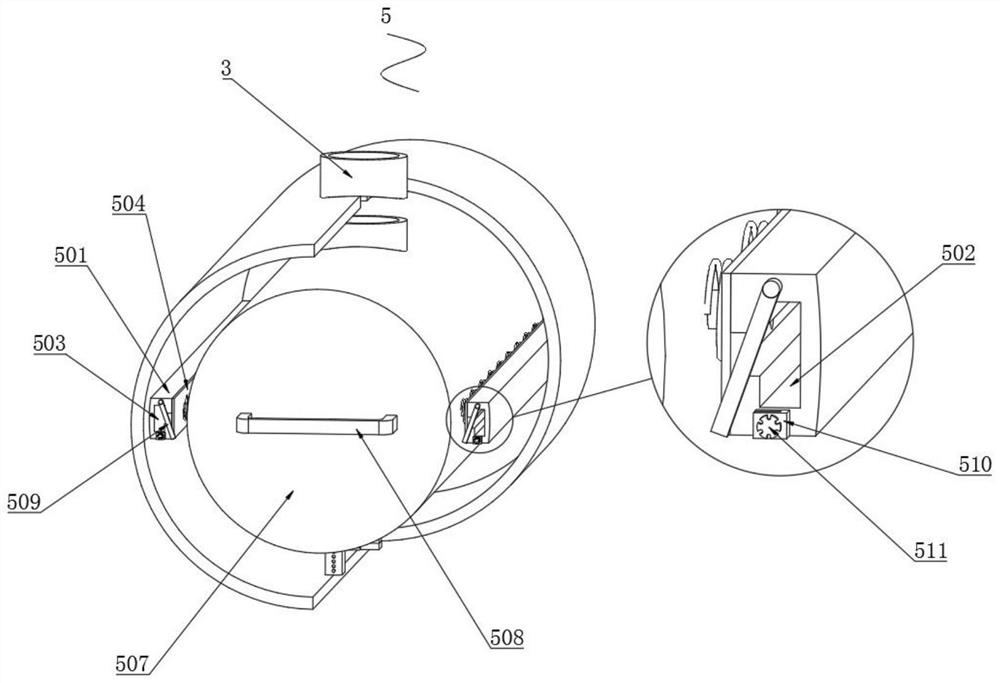

[0049] Example: such as Figure 1-9 As shown, the present invention provides a nuclear science material replacement anti-corrosion system, including a base 1, a storage tank 2 is installed on the top of the base 1 through an adjustment and fixing mechanism 6, and a feed pipe 3 is installed on the outside of the storage tank 2, and the feed pipe 3 A connecting pipe 4 is slidingly installed inside, and a tank cover 9 is installed at one end of the storage tank 2 through a capping mechanism 8. In order to facilitate the replacement of the inner lining 507, it is convenient to supplement the anti-corrosion coating of the inner lining 507 and improve the anti-corrosion of the inner lining 507 As a result, a repair mechanism 5 is arranged inside the storage tank 2;

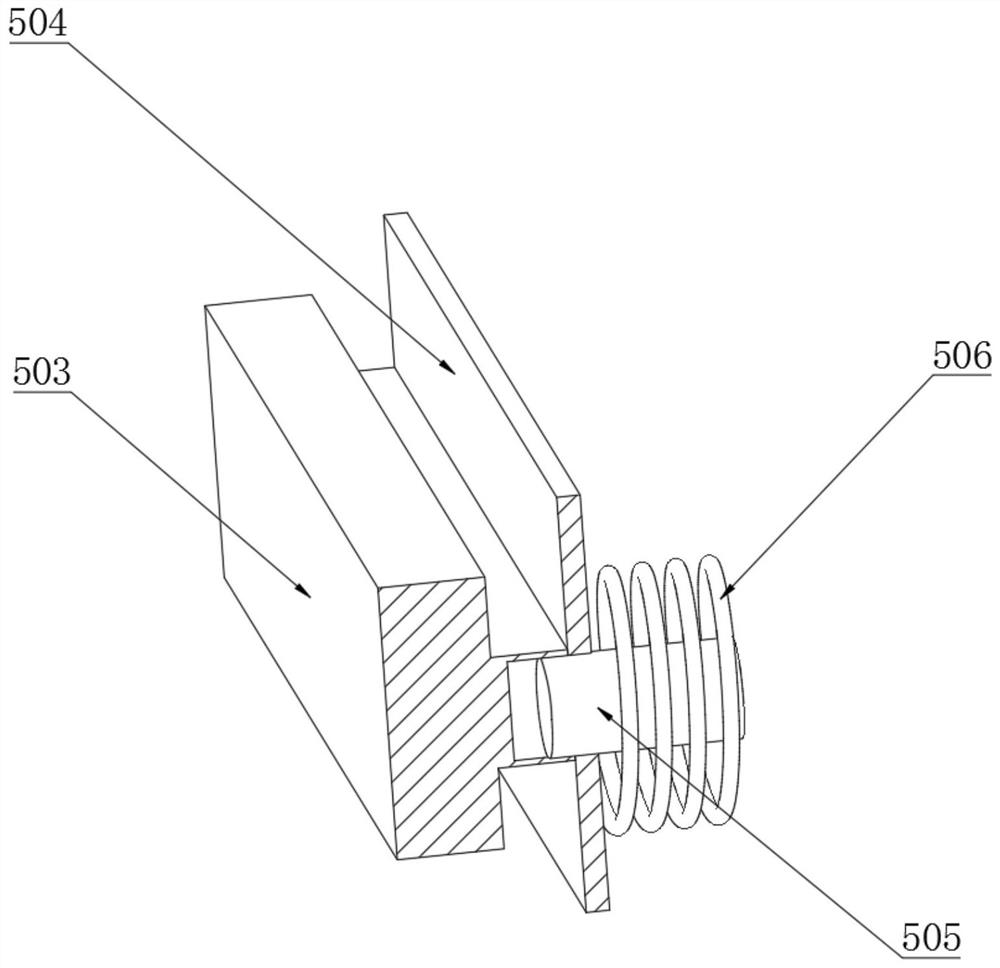

[0050] The repairing mechanism 5 comprises a fixed block 501, a T-shaped groove 502, a T-shaped block 503, a mounting plate 504, a sliding column 505, a connecting spring 506, an inner lining 507, a pull bar 508, a rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com