Light guide optical system capable of saving space and achieving uniform lighting and automobile signal lamp thereof

A space-saving, optical system technology, applied to optical signals, light guides of lighting systems, optics, etc., can solve the problems of cost and light efficiency reduction, high space requirements, etc., to achieve good lighting uniformity, uniform lighting effect, and added diffusion effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

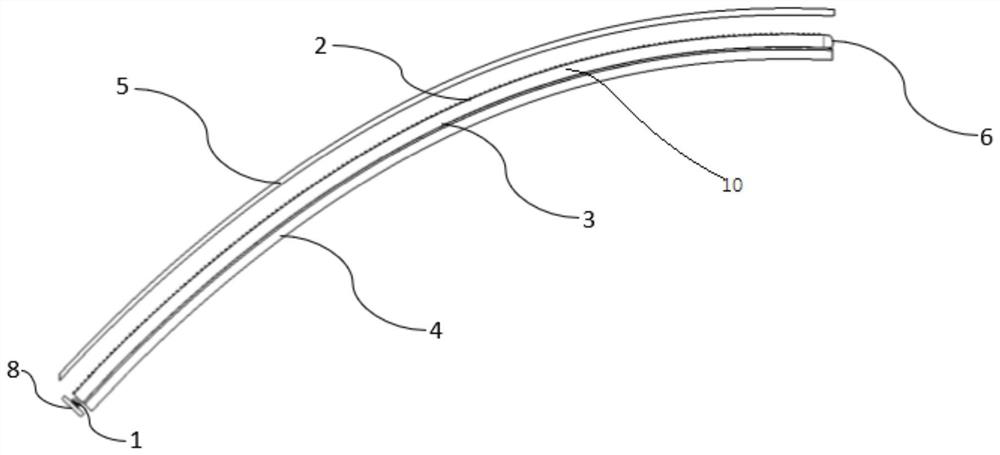

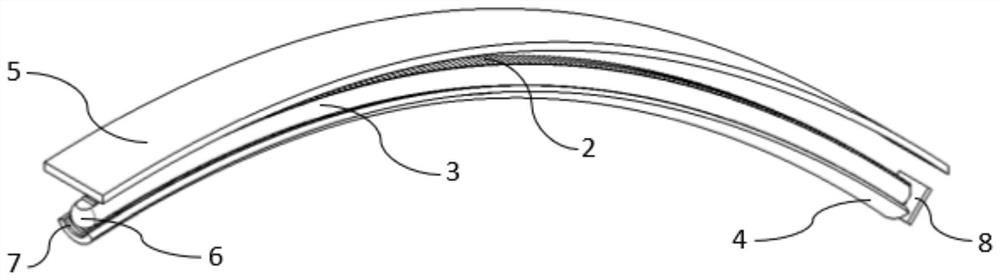

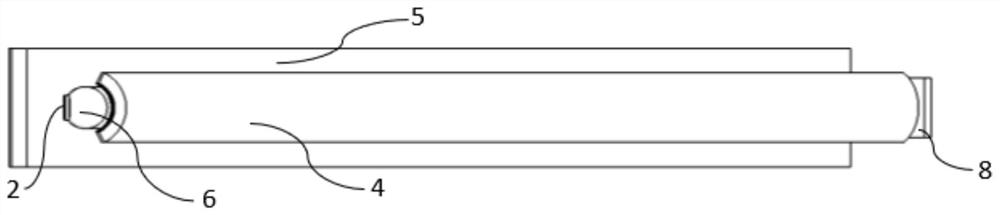

[0044] Such as figure 1 Shown is a structural schematic of a light guide optical system that saves space and achieves uniform lighting Figure 1 ,Such as figure 2 Shown is a structural schematic of a light guide optical system that saves space and achieves uniform lighting Figure II ,Such as image 3 Shown is a top-view diagram of a light guide optical system that saves space and achieves uniform lighting, such as Figure 4 Shown is a schematic top view of a light guide optical system that saves space and achieves uniform lighting, such as Figure 5 Shown is a partial enlargement of the space-saving light guide optics for uniform lighting Figure 1 ,Such as Image 6 Shown is a partial enlargement of the space-saving light guide optics for uniform lighting Figure II, including a light source 1, the light source 1 is fixedly arranged on a circuit board 8, and in this embodiment, the circuit board 8 is arranged on a PCB board. The light source 1 is correspondingly arran...

Embodiment 2

[0050] Embodiment 2 is formed on the basis of Embodiment 1, and the pattern opening direction of the second diffuse optical pattern 9 and the pattern opening direction of the light guide total reflection optical teeth 2 are arranged perpendicular to each other. The second diffusing optical pattern 9 can diffuse the outgoing light in the up and down direction, which can not only expand the lighting area, but also eliminate bright spots, so that the lighting uniformity is better.

Embodiment 3

[0052] Embodiment 3 is formed on the basis of Embodiment 1. The pattern opening direction of the first diffuse optical pattern 7 and the pattern opening direction of the light guide total reflection optical teeth 2 are arranged perpendicular to each other to improve uniformity.

[0053] Working principle: as Figure 7 Shown is a schematic of the optical path of the space-saving light guide optical system for uniform lighting Figure 1 ,Such as Figure 8 Shown is a schematic of the optical path of the space-saving light guide optical system for uniform lighting Figure II , the light guide total reflection optical tooth 2 is arranged on the side of the light guide 10 away from the upper surface of the light guide bracket 4, for this optical system, the effective optical path in the optical design is the distance between the light export light surface and the inner lens light incident surface, which is Figure 8 Middle distance b1+b2. Such as Figure 16 Shown is a schematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com