Testing device for X-ray CT image cross-sectional matching and cross-sectional matching method

A technology of testing devices and matching methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve problems such as interference and maintaining consistent fault matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

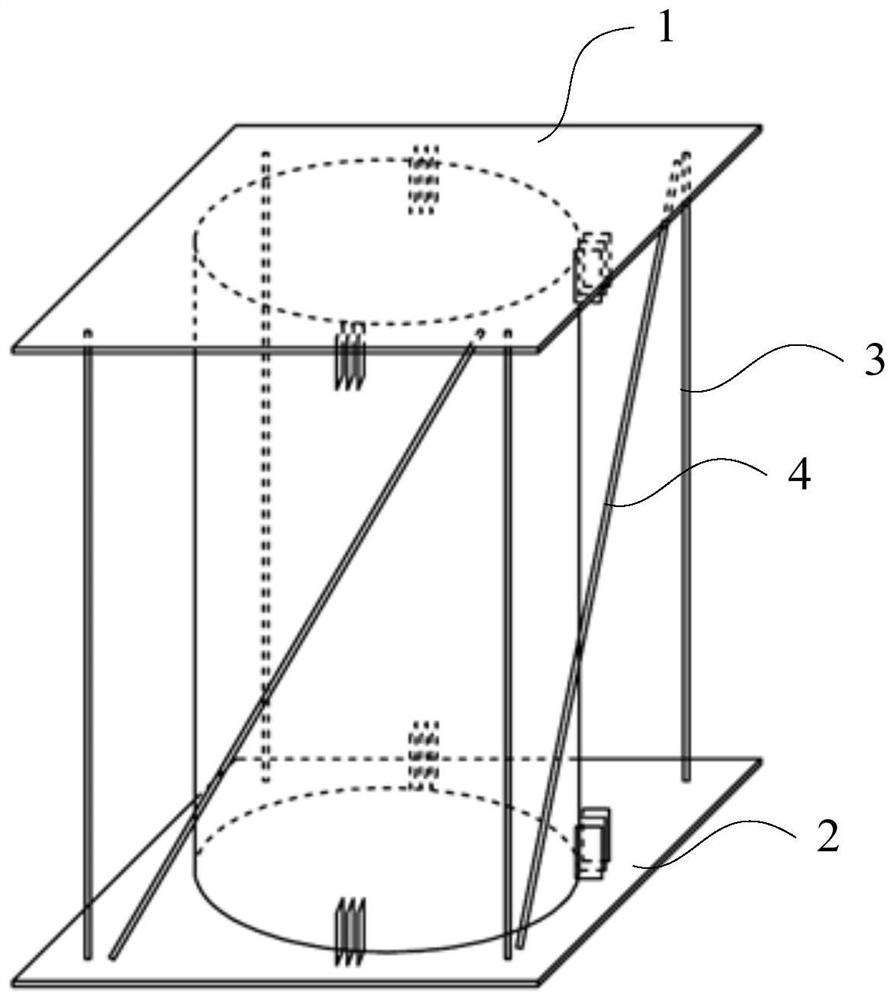

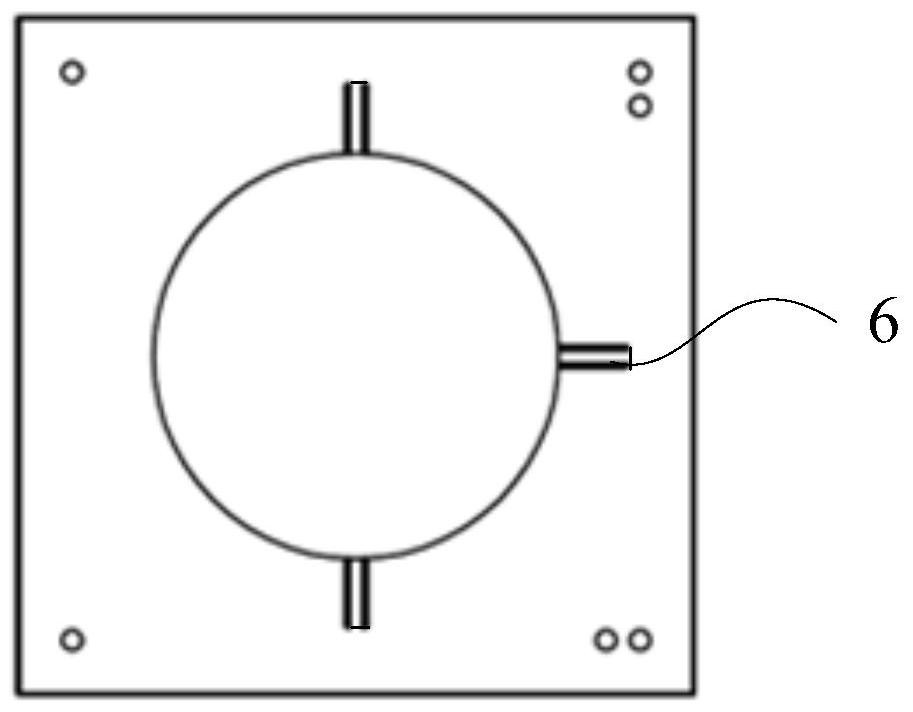

[0043] Specific implementation mode 1. Combination Figure 1 to Figure 3 As shown, the first aspect of the present invention provides a test device for tomographic matching of X-rayCT images, including an upper end plate 1, a lower end plate 2, four vertical support rods 3 and two oblique marker rods 4,

[0044] Four vertical support rods 3 are evenly arranged and supported between the upper end plate 1 and the lower end plate 2, the inner space formed by the upper end plate 1, the lower end plate 2 and the four vertical support rods 3 is used for installing the scanning specimen, scanning test piece Azimuths are fixed between the upper end plate 1 and the lower end plate 2 through the fixing parts respectively;

[0045]Among the three adjacent vertical support rods 3 , an oblique marking rod 4 is arranged between every two adjacent vertical supporting rods 3 , and the inclinations of the two oblique marking rods 4 are the same.

[0046] In this embodiment, the vertical suppo...

specific Embodiment approach 2

[0055] Specific embodiment two, combine Figure 1 to Figure 4 As shown, another aspect of the present invention also provides an X-rayCT image tomographic matching method, which is implemented based on the test device for X-rayCT image tomographic matching described in the first specific embodiment, including:

[0056] First, install the scanning specimen in the initial state in the test device, perform a reference tomographic scan, and obtain a reference tomographic image;

[0057] Then, take out the scanned specimen in the initial state for damage test;

[0058] Installing the scanned specimen after the damage test in the test device, performing a post-damage tomographic scan, and obtaining a post-damage tomographic image;

[0059] In the reference tomographic image, through the distance between each oblique marking rod 4 and two adjacent vertical support rods 3, calculate the reference height mark value of the reference tomographic image at the height position of the scann...

specific Embodiment

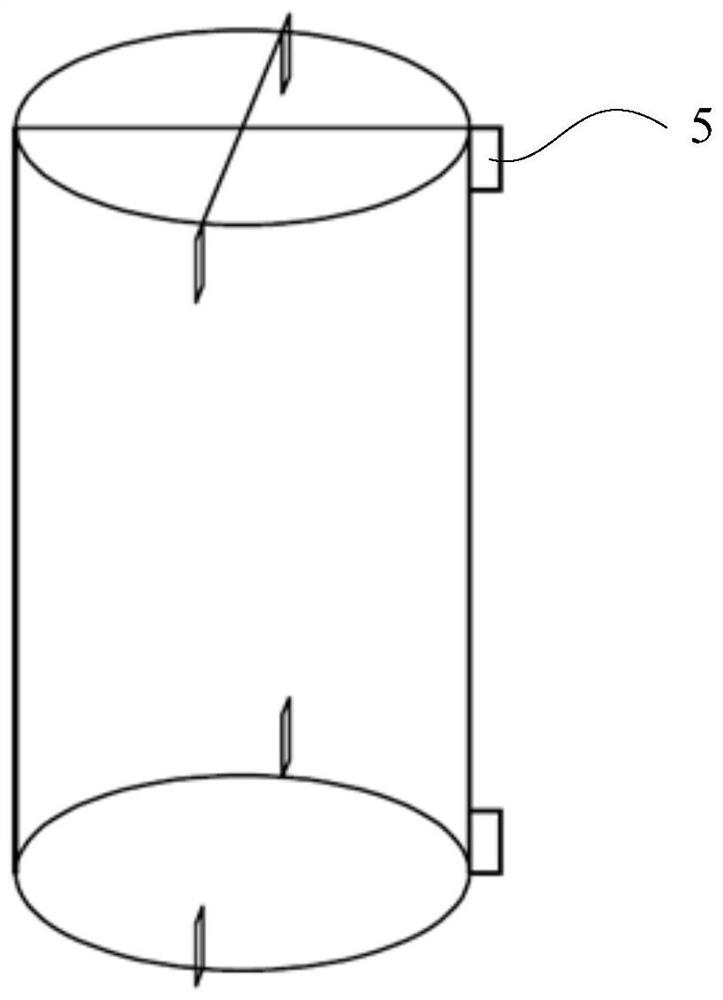

[0091] combine Figure 1 to Figure 4 , taking the tomographic image matching before and after freeze-thaw damage of asphalt mixture as an example, the specific implementation of the present invention is described in detail:

[0092] Step 1: Bonding of the fixed clip:

[0093] On the cylindrical asphalt mixture specimen, mark the cross line of the specimen through the center of the circle to determine the quartile position of the side wall of the specimen, see appendix figure 2 As shown: AB glue is used to bond the metal fixing clips and fix them on the side wall of the quarter position. A total of 6 fixing clips are bonded, and the upper and lower positions correspond to each other. After the AB glue is solidified, install the upper and lower end plates of the fixture on the upper and lower bottom surfaces of the specimen, and test whether the position of the fixing clip is appropriate. If the fixing clip cannot be placed in the clip groove, it needs to be bonded again until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com