Air energy curing barn capable of being remotely monitored and monitoring method thereof

A technology of remote monitoring and air energy, which is applied in the field of barns, can solve problems such as troublesome use of air barns, achieve the effects of enhancing heat insulation, preventing backflow, and improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

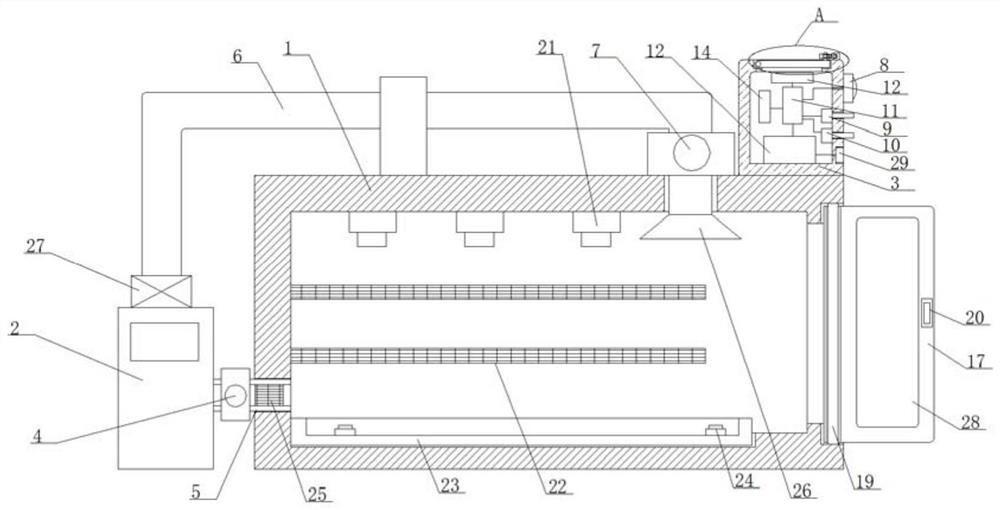

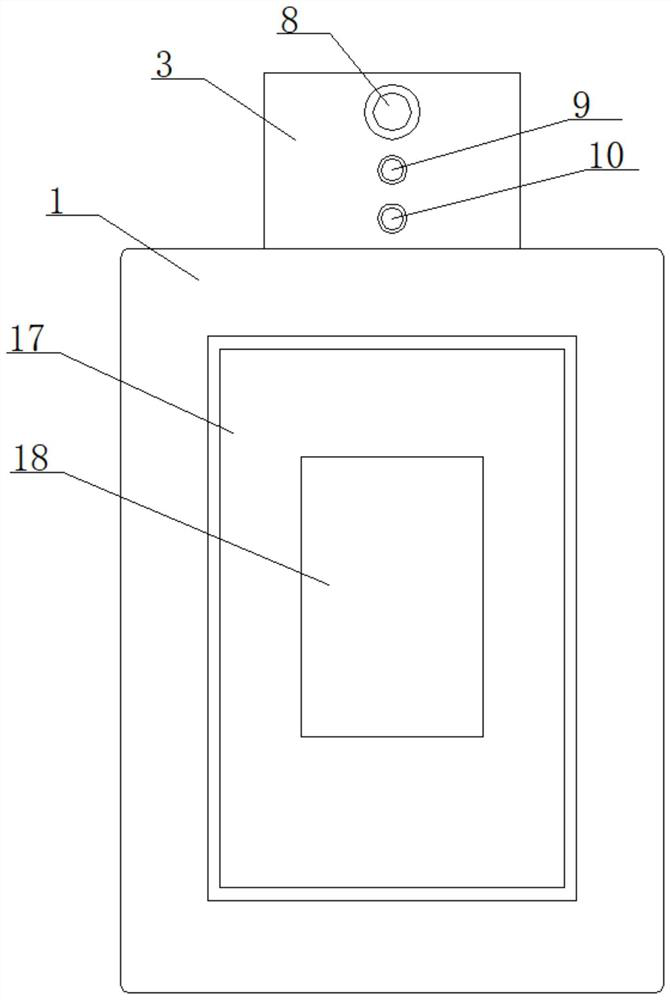

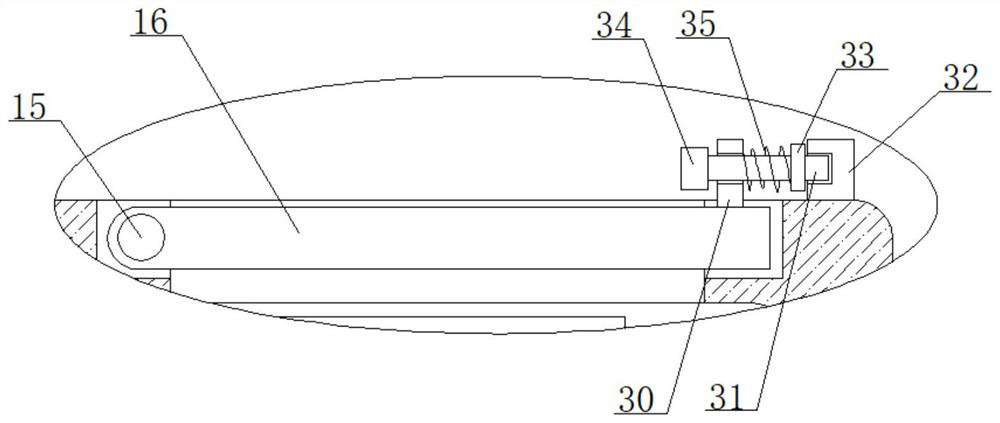

[0038] refer to Figure 1-4 , an air energy barn that can be remotely monitored, including barn body 1, heat pump host 2 and control box 3, the output end of heat pump host 2 is fixedly connected with circulation fan 4, which facilitates the circulation of hot air, and the output end of circulation fan 4 is connected to the oven The room body 1 is connected through the air inlet pipe 5, and a filter screen 25 is fixedly inserted in the air inlet pipe 5 to filter the hot air. The top of the barn body 1 is fixedly inserted with an air outlet pipe 6 for introducing hot air into the barn In the main body 1 , the air outlet pipe 6 is fixedly sleeved with a shroud 26 at one end located in the barn body 1 , so as to facilitate the introduction of hot air into the air outlet pipe 6 .

[0039] In the present invention, a self-priming pump 7 is threaded on the air outlet pipe 6 for introducing air into the air outlet pipe 6, and a check valve 27 is threaded on the end of the air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com