Root cause positioning method and device for abnormal production, equipment, medium and product

A positioning method and root cause technology, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as low accuracy of root cause positioning, and achieve the effect of solving low accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

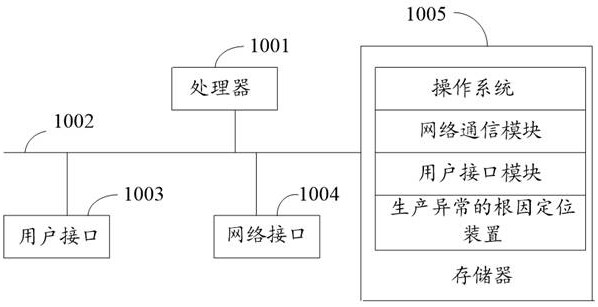

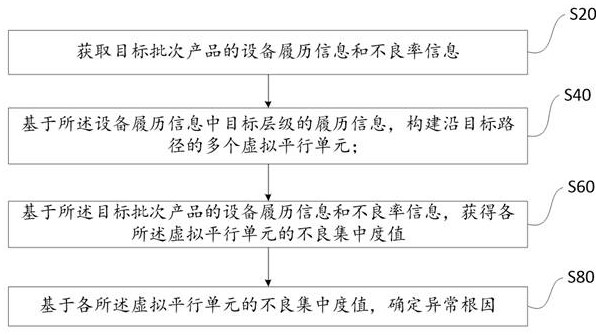

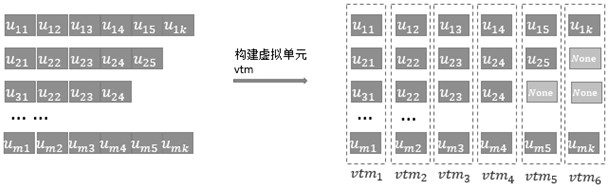

[0059] The main solution of the embodiment of the present application is to provide a root cause location method, device, equipment, medium, and product for production abnormalities. The method obtains equipment history information and defect rate information of the target batch of products; wherein, the The equipment history information includes the history information of the root cause unit of the target batch of products at different levels; based on the history information of the target level in the equipment history information, a plurality of virtual parallel units along the target path are constructed; wherein, the target The path is the path of the target batch of products at the target level; the virtual parallel unit includes virtual units generated by the products in the target batch of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com