Cotton filling machine for doll production and use method

A technology for toys and dolls, applied in the field of toy production equipment, can solve the problems of incomplete breaking up, inability to remove impurities, affecting production, etc., and achieve the effects of good detection function, good softness, and improved toy quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Feeding and removing impurities

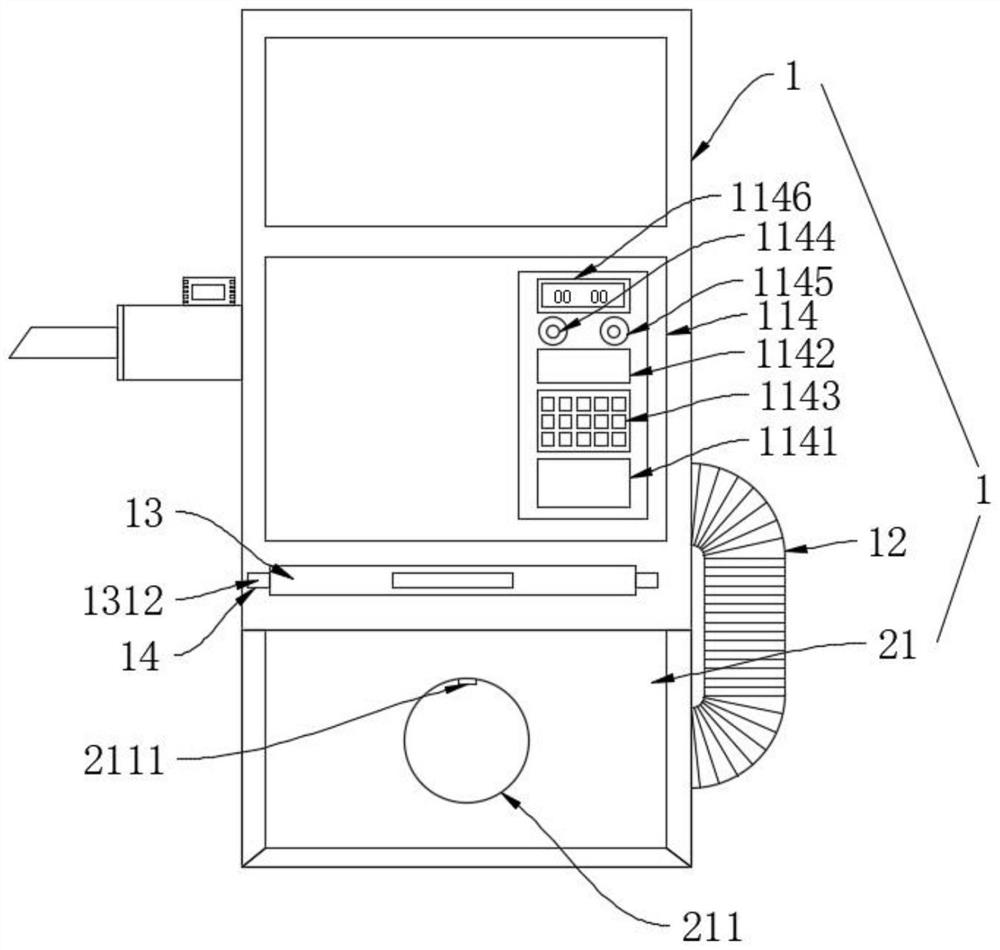

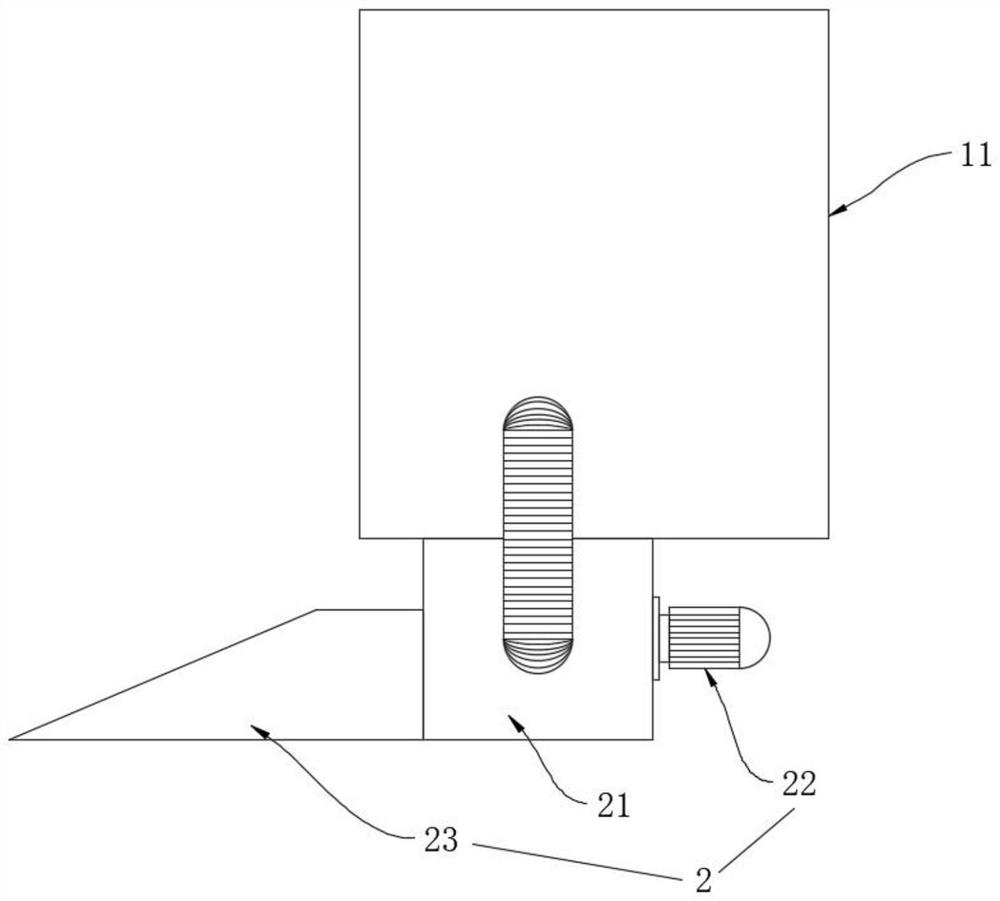

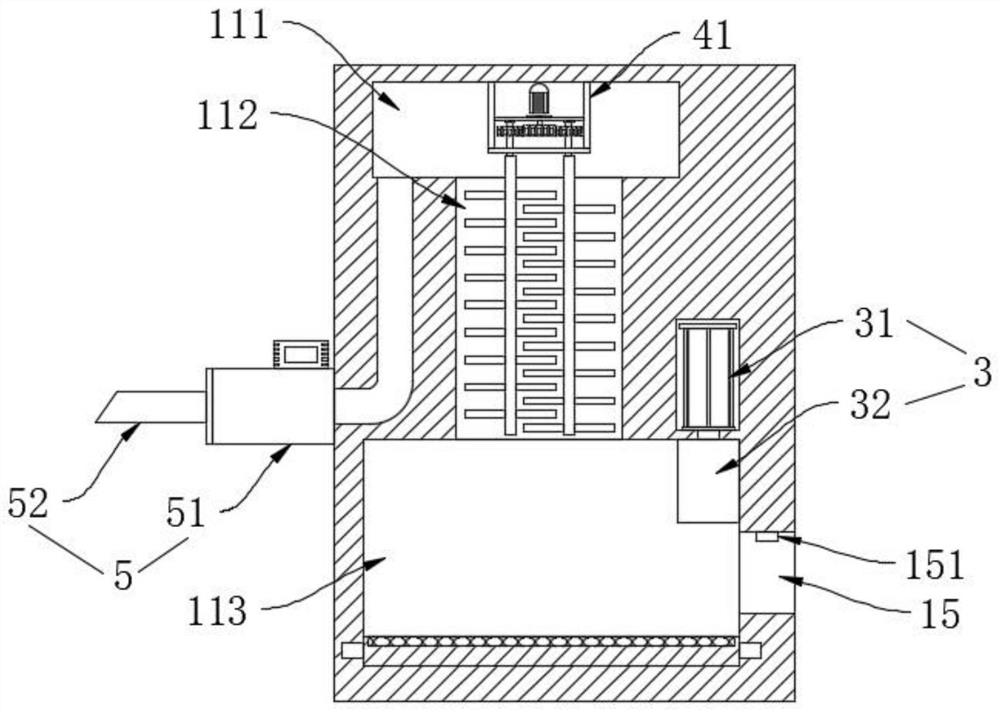

[0038]Including the main body assembly 1, the main body assembly 1 includes the cotton sending assembly 2 and the processing box 11, the cotton sending assembly 2 includes the casing 21, the induced draft fan 22 and the collecting bucket 23, the induced draft fan 22 is installed in the casing 21, and the collecting bucket 23 is welded on One side of the casing 21, the front side of the casing 21 is provided with a feed inlet 211, the processing box 11 is installed on the top of the casing 21 by bolts, and the processing box 11 is provided with a discharge chamber 111, a breaking chamber 112 and a transition chamber 113, and discharge Chamber 111, breaking chamber 112 and transition chamber 113 are arranged sequentially from top to bottom. One side of transition chamber 113 is provided with a port 15. Auxiliary assembly 3 and breaking assembly 4 are arranged, cotton filling assembly 5 is arranged on one side of processing b...

Embodiment 2

[0040] Embodiment 2: multi-stage fluffy processing

[0041] Including the main body assembly 1, the main body assembly 1 includes the cotton sending assembly 2 and the processing box 11, the cotton sending assembly 2 includes the casing 21, the induced draft fan 22 and the collecting bucket 23, the induced draft fan 22 is installed in the casing 21, and the collecting bucket 23 is welded on One side of the casing 21, the front side of the casing 21 is provided with a feed inlet 211, the processing box 11 is installed on the top of the casing 21 by bolts, and the processing box 11 is provided with a discharge chamber 111, a breaking chamber 112 and a transition chamber 113, and discharge Chamber 111, breaking chamber 112 and transition chamber 113 are arranged sequentially from top to bottom. One side of transition chamber 113 is provided with a port 15. Auxiliary assembly 3 and breaking assembly 4 are arranged, cotton filling assembly 5 is arranged on one side of processing bo...

Embodiment 3

[0043] Example 3: Blockage Detection

[0044] Including the main body assembly 1, the main body assembly 1 includes the cotton sending assembly 2 and the processing box 11, the cotton sending assembly 2 includes the casing 21, the induced draft fan 22 and the collecting bucket 23, the induced draft fan 22 is installed in the casing 21, and the collecting bucket 23 is welded on One side of the casing 21, the front side of the casing 21 is provided with a feed inlet 211, the processing box 11 is installed on the top of the casing 21 by bolts, and the processing box 11 is provided with a discharge chamber 111, a breaking chamber 112 and a transition chamber 113, and discharge Chamber 111, breaking chamber 112 and transition chamber 113 are arranged sequentially from top to bottom. One side of transition chamber 113 is provided with a port 15. Auxiliary assembly 3 and breaking assembly 4 are arranged, cotton filling assembly 5 is arranged on one side of processing box 11, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com