Turnover film pasting device and film pasting system

A film sticking device and film sticking technology are applied in the field of flip film sticking device and film sticking system, which can solve the problems of cumbersome process, large overall size of the device, affecting the film sticking efficiency, etc., and achieve the effect of reducing the overall volume and improving the film sticking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

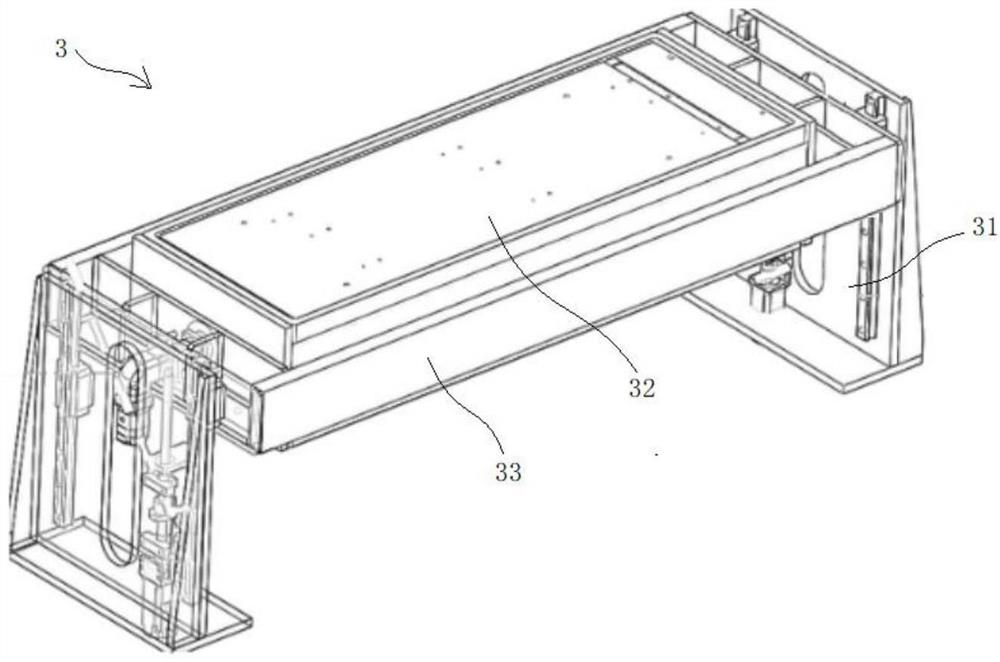

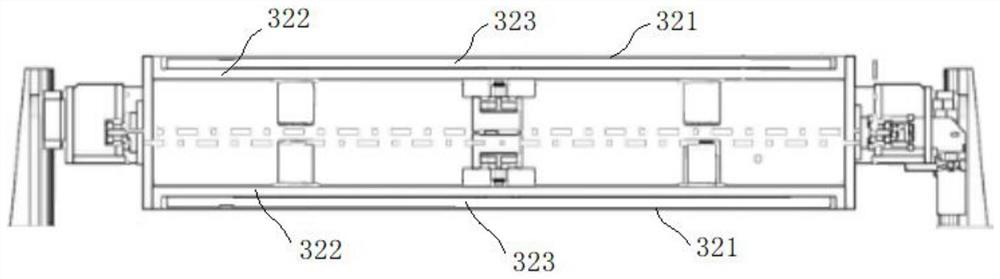

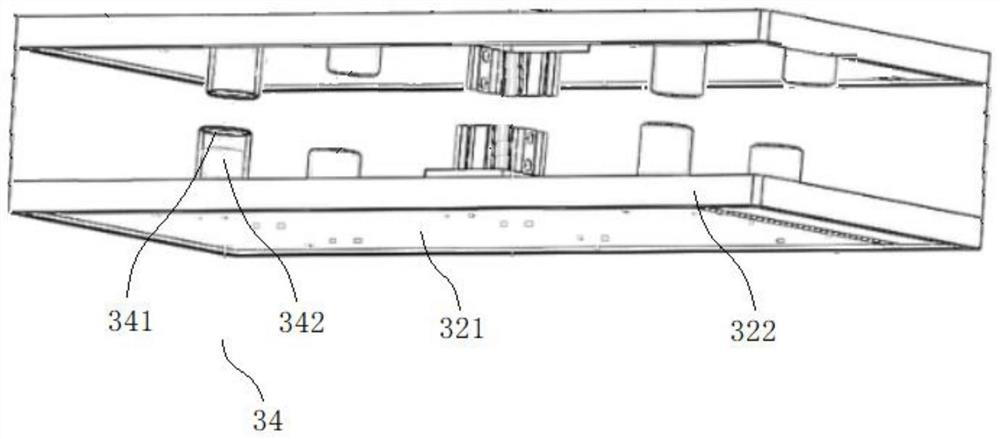

[0051] The embodiment of the present invention provides a flipping film sticking device 3 and a film sticking system, which will be described in detail below with reference to the accompanying drawings. For simplicity, only those elements relevant to the subject matter of the text are shown. The overall vacuum suction assembly can have many other configurations and many other types of equipment can be used.

[0052] Specifically, such as Figure 1 to Figure 4As shown, a flipping film sticking device 3 is disclosed. The flipping film sticking device 3 includes a support frame 31, a frame 33, a flipping film sticking fixture 32 and a driving member. The support frame 31 is supported on the base of the film sticking system; the frame 33 is slidably mounted on the support frame 31, and the sliding frame 33 slides along the support frame 31 toward or away from the base The overturning film sticking fixture 32 is rotatably installed in the frame 33, the turning over film sticking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com