Precipitation-preventing printer ink cartridge

A printer and anti-precipitation technology, applied in printing and other directions, can solve the problems of ink precipitation, changes in the clarity of printing effects, and easy leakage of ink during ink filling, so as to avoid liquid leakage and static precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

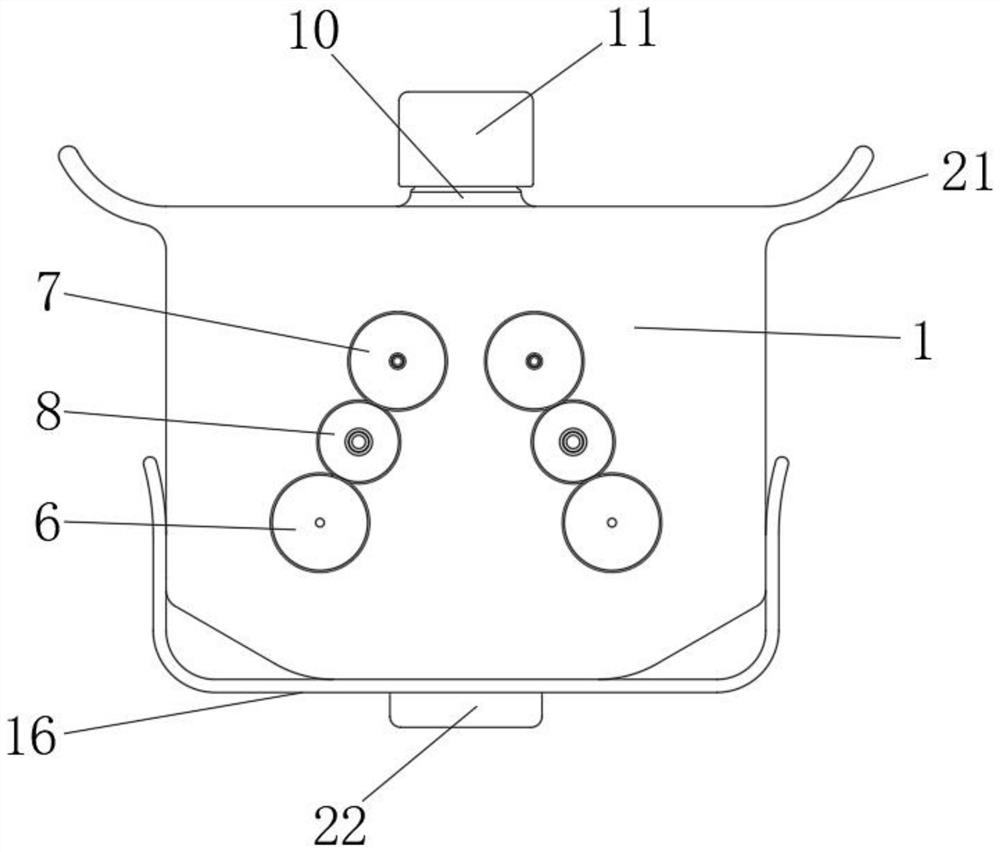

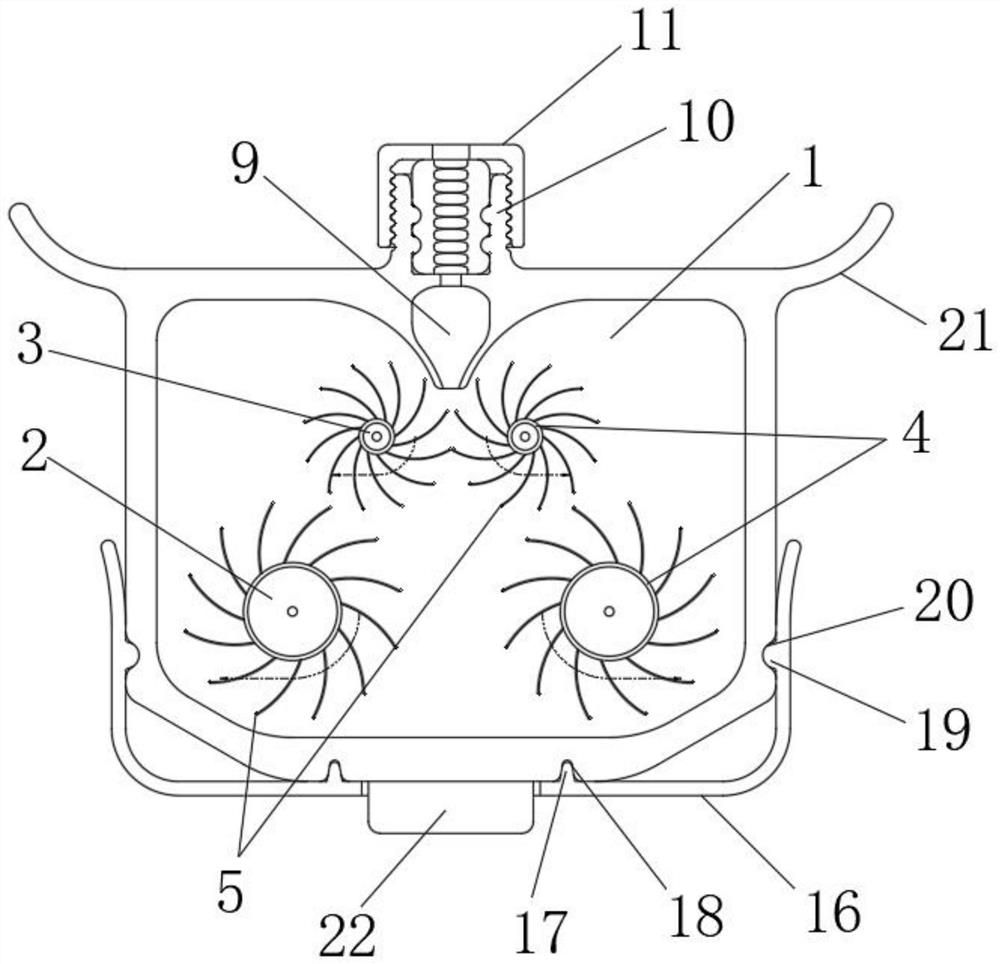

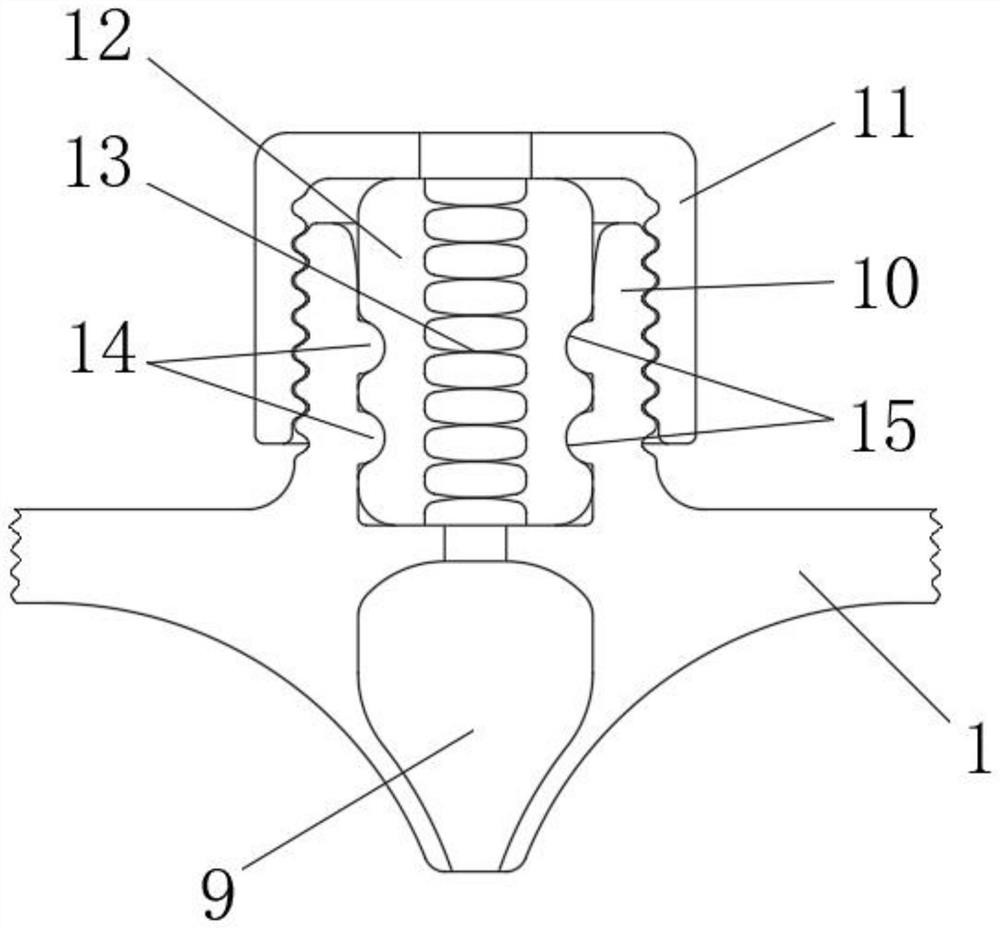

[0024] see Figure 1-4 , the present invention provides a technical solution: a sedimentation-proof printer ink cartridge, including an ink cartridge body 1, and a print head 22 installed at the lower end of the ink cartridge body 1, an electric roller 2 and a driven roller 3 are installed inside the ink cartridge body 1, and The output shaft at one end of the motorized roller 2 is fixed to the inner wall of the ink cartridge body 1, and the driven roller 3 is located above the motorized roller 2, and there are two motorized rollers 2 and driven rollers 3 installed inside the ink cartridge body 1, which are symmetrically arranged. The outer surfaces of the roller 2 and the driven roller 3 are fixed with a rubber sleeve 4, and the outer surface of the rubber sleeve 4 is integrally formed with a stirring plate 5. The center rod at the other end of the electric roller 2 is connected to the ink cartridge body 1 in rotation, and the electric roller 2 is separately The central rod a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com