Pumping system quality control system and method

A technology of pumping system and control system, applied in special data processing applications, geometric CAD and other directions, can solve problems such as affecting the performance and life of concrete pump trucks, pumping system jitter, pumping system coaxiality out of tolerance, etc. Achieve the effect of realizing quality traceability, improving assembly quality and efficiency, and reducing unqualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

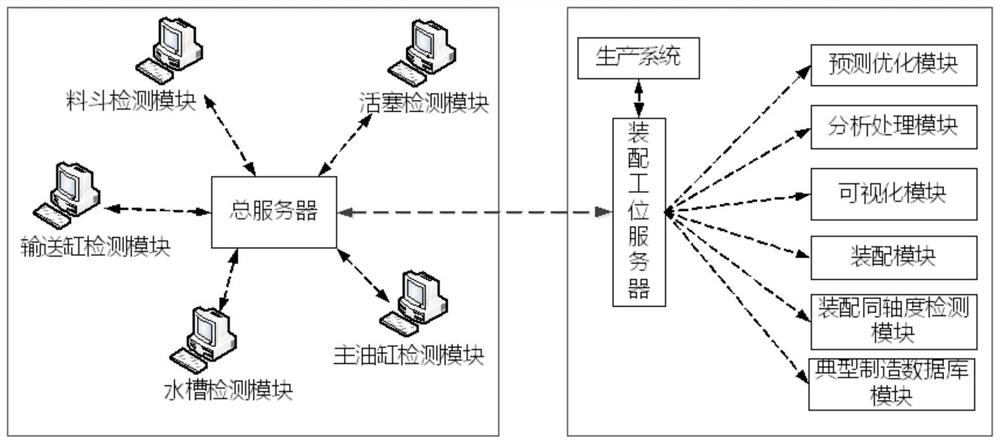

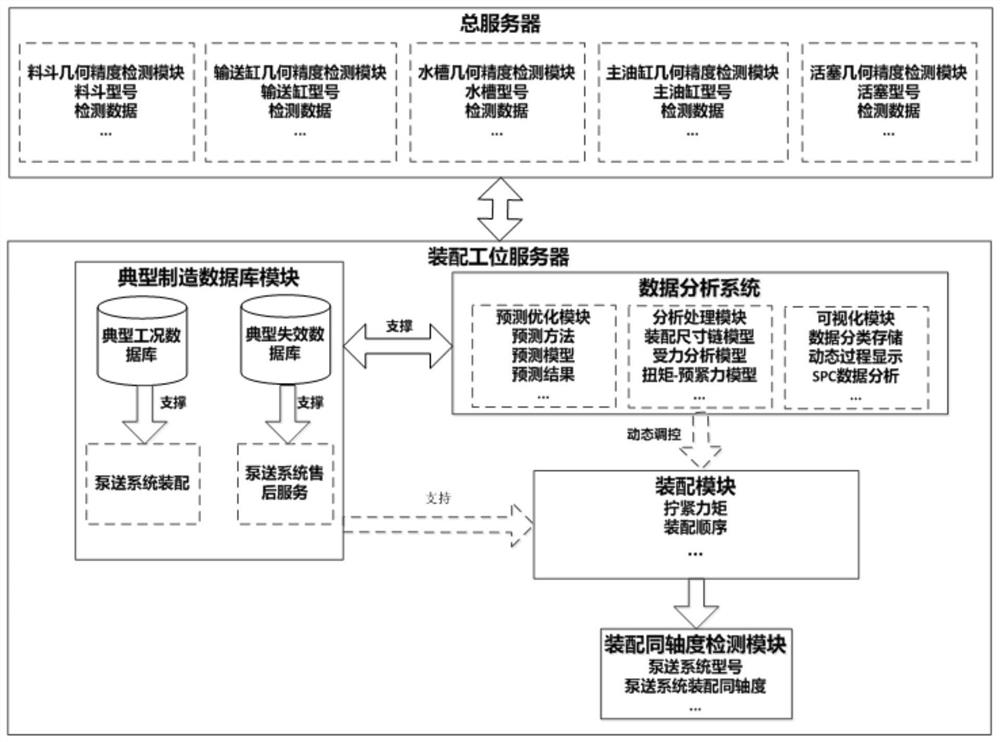

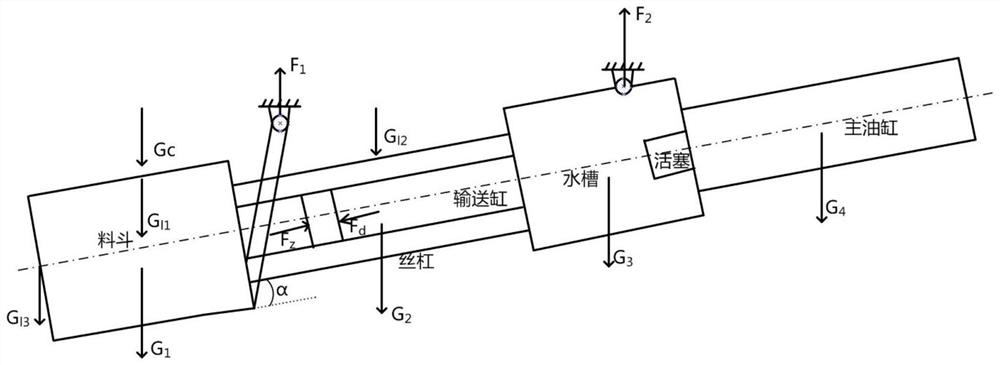

[0055] An embodiment of the present invention provides a pumping system quality control system, the pumping system includes a hopper, a delivery cylinder, a water tank, a main oil cylinder and a piston, the two ends of the delivery cylinder are respectively connected to the hopper and the water tank, the The hopper and the water tank are fixed by a screw, the main oil cylinder and the water tank are connected by bolts, and the piston is installed on the main oil cylinder. For details, please refer to image 3 , the pumping system quality control system specifically includes: a data acquisition module, a general server and an assembly station server, see for details figure 1 .

[0056] The data acquisition module is used to collect the production data and geometric accuracy data of each component in the pumping system; in the specific implementation process, the data acquisition module includes a hopper geometric accuracy detection module, a conveying cylinder geometric accurac...

Embodiment 2

[0099] A method for quality control of a concrete pumping system is provided in an embodiment of the present invention, comprising the following steps:

[0100] Step (1) Utilize the data acquisition module to collect the production data and geometric accuracy data of each component in the pumping system;

[0101] Step (2) Utilize the main server connected to the data acquisition module, based on the production data and geometric accuracy data of each component, identify the geometric accuracy data that affects the assembly coaxiality, and define it as key geometric accuracy data;

[0102] Step (3) Using the assembly station server connected to the main server, based on the key geometric accuracy data, calculate the torque required by the key connection parts to form an optimal assembly plan, and based on the optimal assembly plan , to assemble the pumping system.

[0103] In a specific implementation of the embodiment of the present invention, the data acquisition module incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com