Jig for accurately positioning upper lampshade of high-brightness backlight double-lampshade structure

A technology of backlight source and double lampshade is applied in the field of accurate lampshade positioning fixture on the structure of high brightness backlight source and double lampshade. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

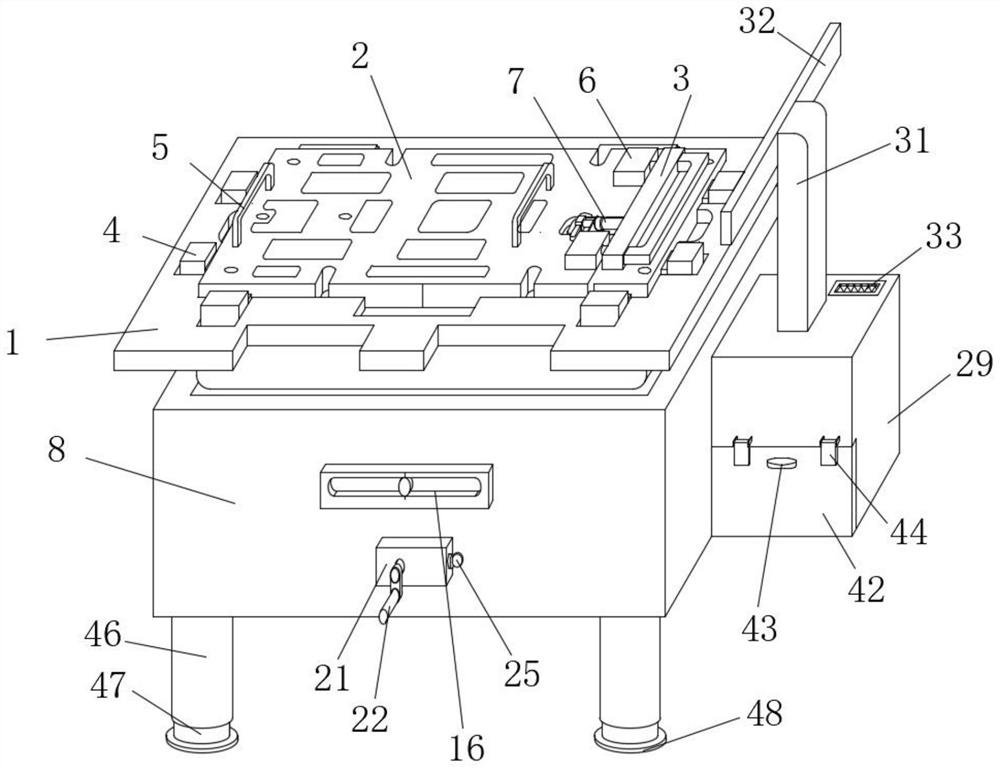

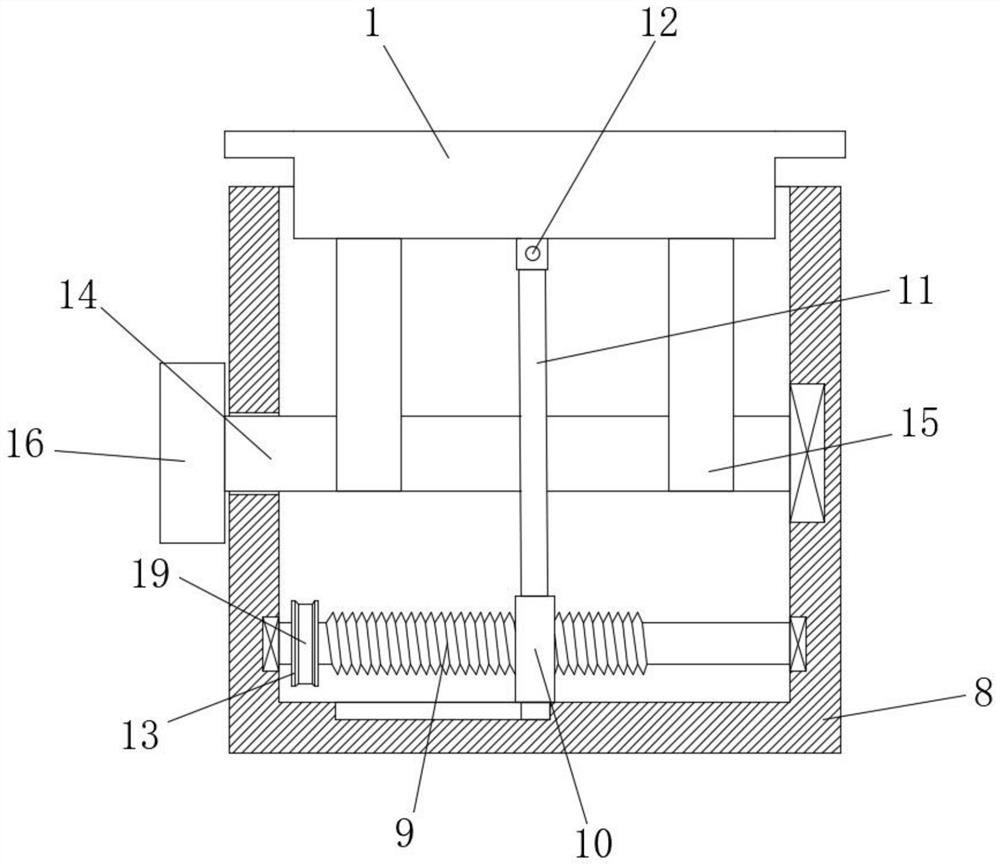

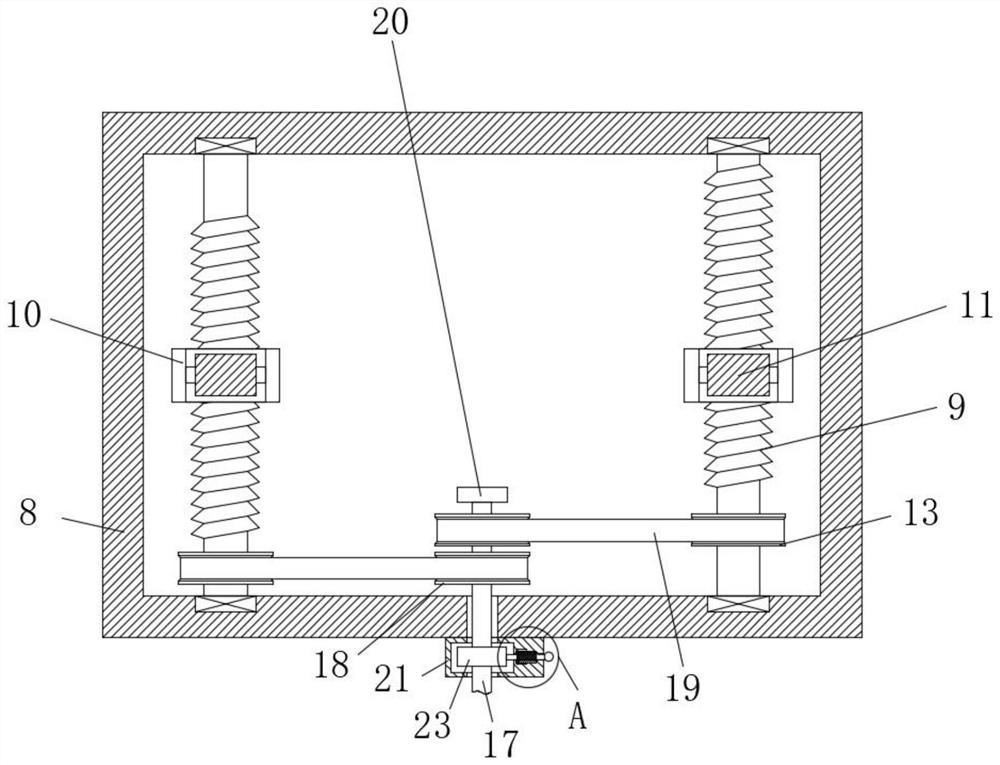

[0038] Embodiment 1: A high-brightness backlight double lampshade structure upper lampshade precise positioning jig, including a fixed seat 1, a positioning plate 2, a telescopic device, a limit block 3, a fixed block 4, a handle 5, a leveling device, a rotating device, a limiter Positioning device, dust suction device, air filter device, dust removal device, closing device and height adjustment device, the positioning plate 2 is set on the top of the fixed seat 1, and the telescopic device is configured to be connected with the positioning plate 2, and the telescopic device is installed on the right side of the top of the positioning plate 2, the limit block 3 is configured to be on the right side of the telescopic device, and the fixed block 4 is arranged on the fixed seat 1 around the top, the handle 5 is arranged on both sides of the top of the positioning plate 2, the rotating device is configured to cooperate with the leveling device, and the limiting device is configured...

Embodiment 2

[0039] Embodiment 2: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis of it. Specifically, a high-brightness backlight double lampshade structure upper lampshade precision fixture is provided, including Fixed seat 1, positioning plate 2, telescopic device, limit block 3, fixed block 4, handle 5, leveling device, rotating device, limit device, dust suction device, air filter device, dust discharge device, closing device and adjustment High device, the positioning plate 2 is set on the top of the fixed seat 1, the telescopic device is configured to cooperate with the positioning plate 2, and the telescopic device is installed on the right side of the top of the positioning plate 2 side, the limiting block 3 is configured to be on the right side of the telescopic device, the fixing block 4 is arranged around the top of the fixing seat 1, and the handle 5 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com