Drum paper assembling method

An assembly method and drum paper technology, applied in the direction of sensors, electrical components, diaphragm structures, etc., can solve the problems of automatic production line shutdown, affecting production progress, reducing product yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

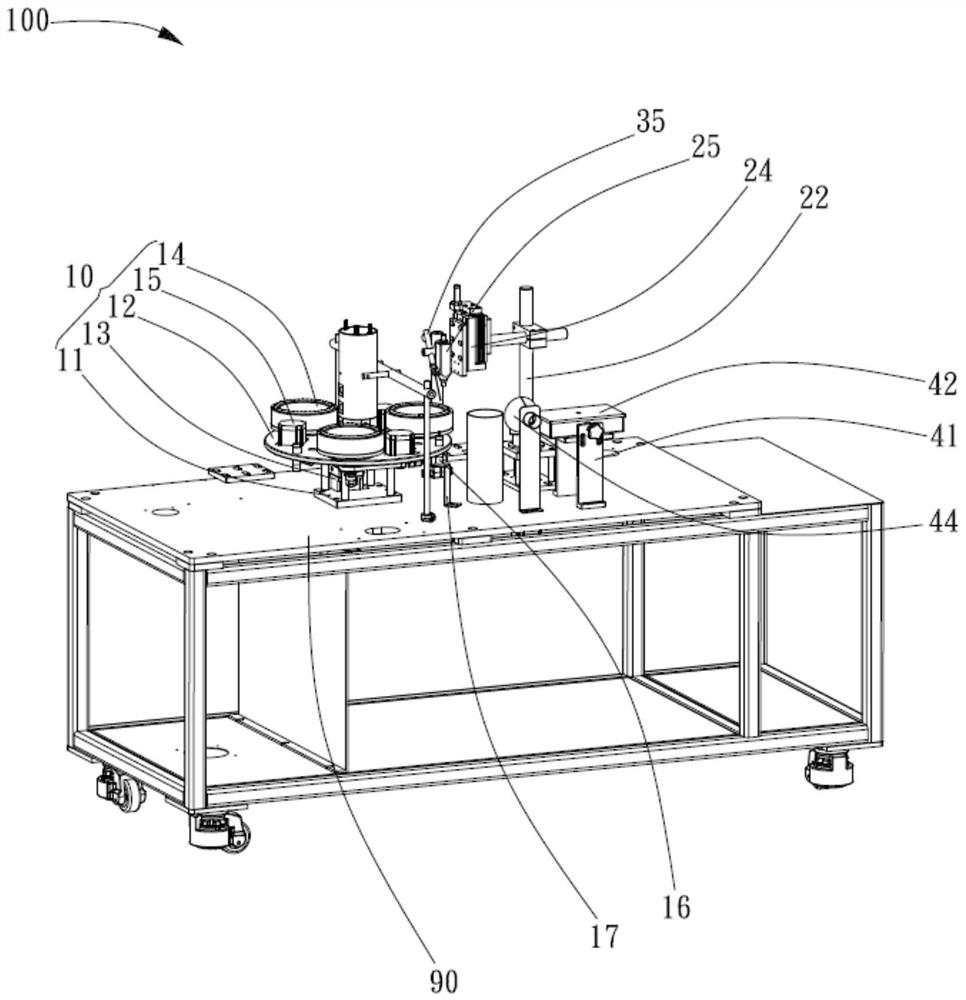

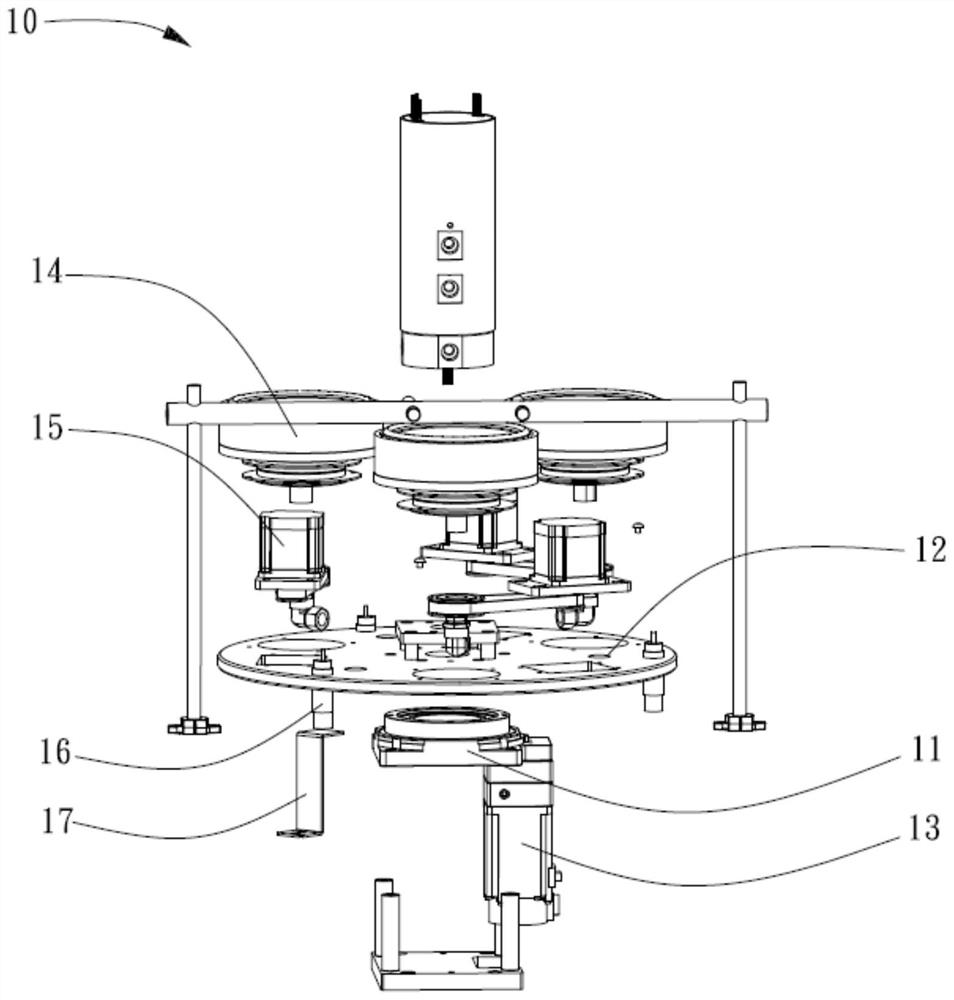

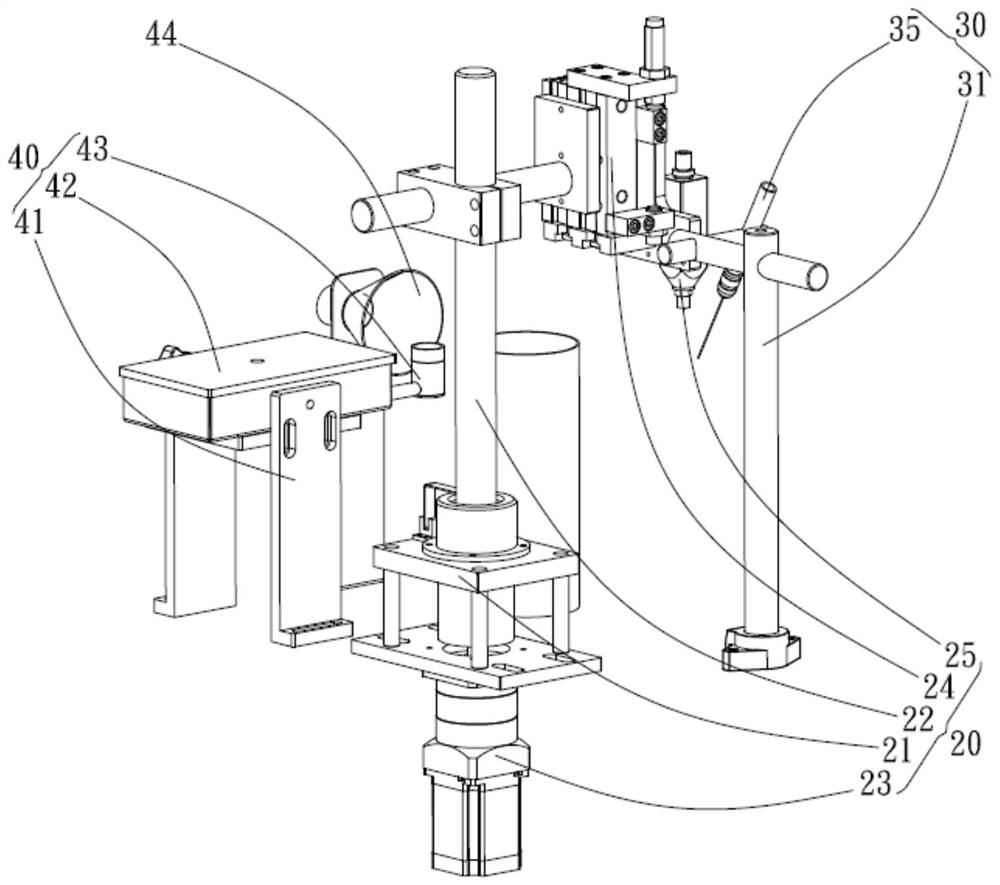

[0033] The drum paper assembly method described in the embodiment of the present invention comprises the following steps:

[0034] S1. Form the foam material, and cut off the middle part at the same time to form a semi-finished product of the vibrating ring;

[0035] S2, pasting the vibration ring semi-finished product on the outer edge of the drum paper carcass to obtain the assembly;

[0036] S3. The assembly is positioned at the center of the drum paper carcass, and the vibrating ring semi-finished product of the assembly is punched to remove the excess to obtain a finished product.

[0037] The foam material is formed first, and the middle part is cut off at the same time of forming, leaving the remaining material on the edge, and then it is combined with the drum carcass, and then the remaining material on the edge is cut off, so that the remaining material on the edge can be grasped when moving the semi-finished product of the vibrating ring , In this way, it will not t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap