Automatic punching detection equipment for shaft tube products

A technology for testing equipment and products, applied in metal processing equipment, perforating tools, chemical instruments and methods, etc., can solve problems such as low detection efficiency, achieve the effect of saving labor costs, improving overall efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

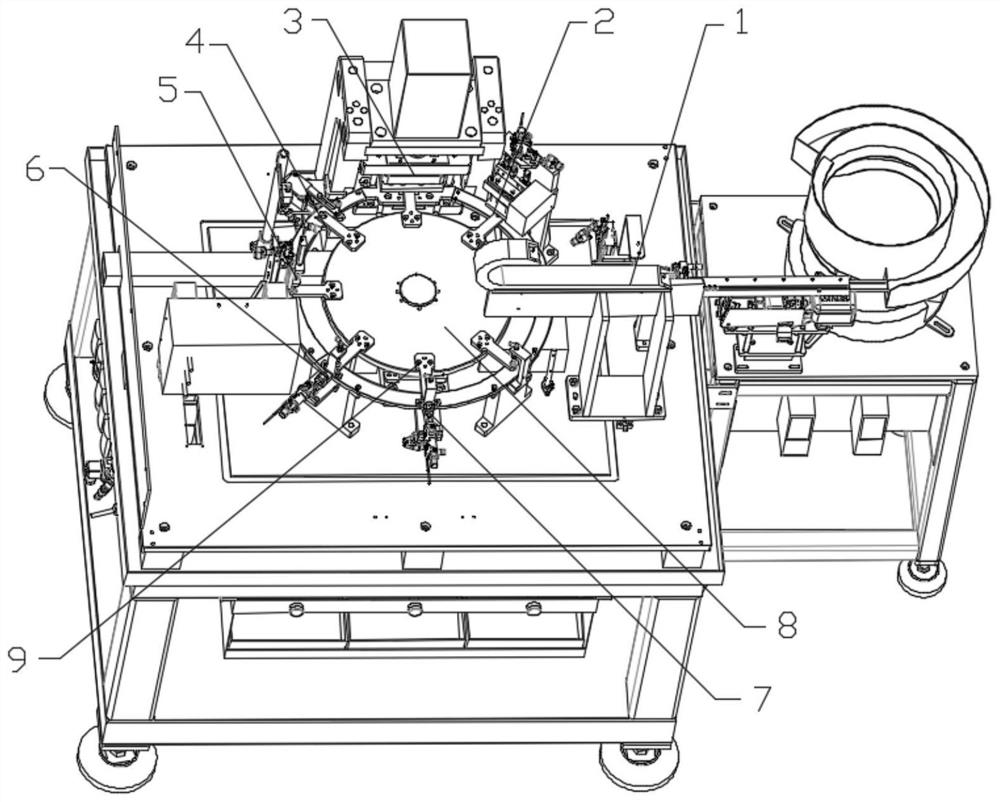

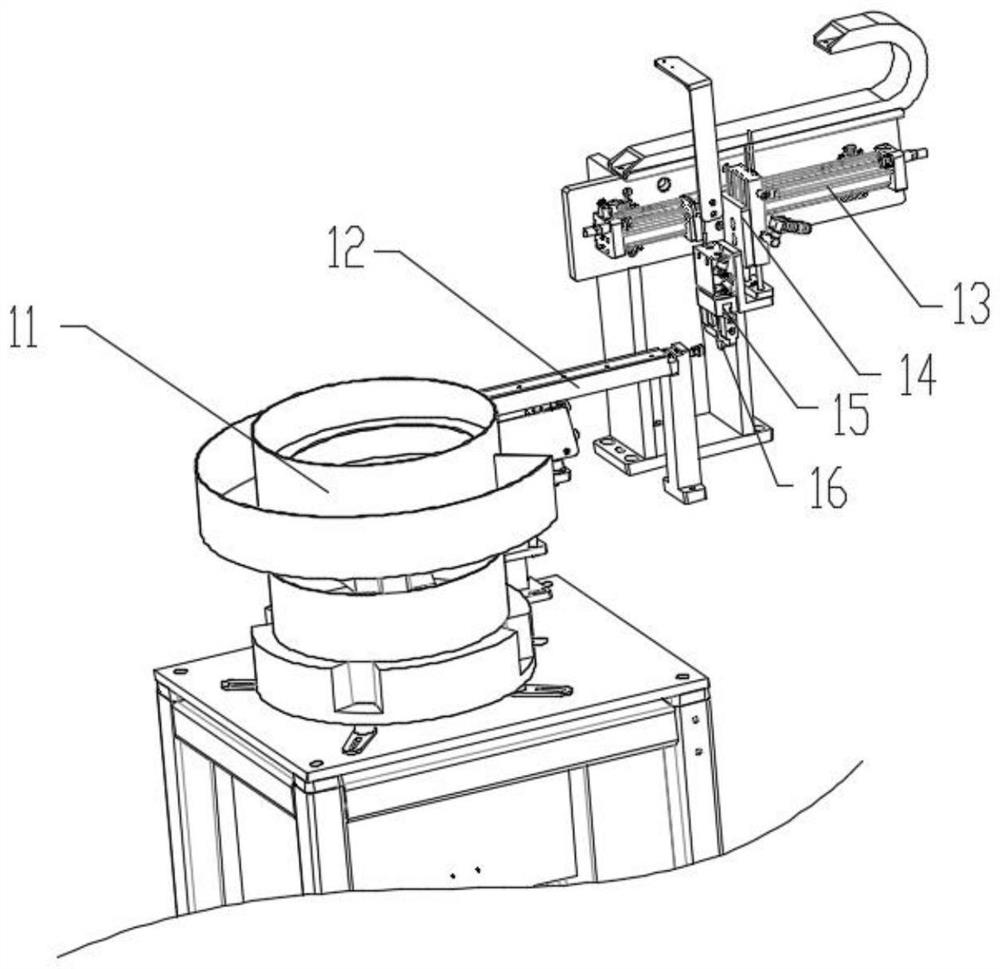

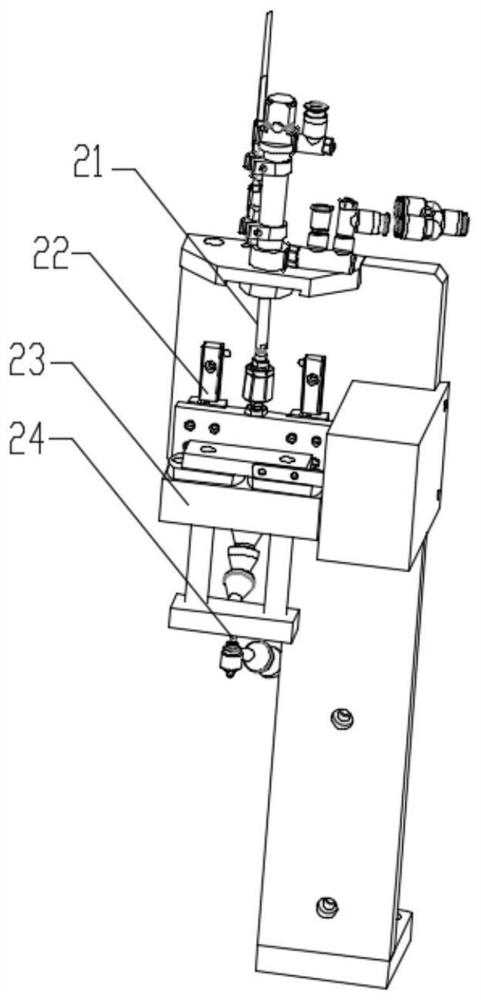

[0024] Such as figure 1 As shown, an automatic punching detection equipment for shaft tube products includes: an indexing plate 8, where a feeding mechanism 1, a positive and negative detection mechanism 2, a punching mechanism 3, a blowing Gas mechanism 4, detection mechanism 5, first blanking mechanism 6, second blanking mechanism 7, a circle of baffles 10 are arranged on the periphery of said indexing plate 8, said baffles 10 are arranged on the punching mechanism 3, the second The first feeding mechanism 6 and the second feeding mechanism 7 are respectively provided with a through hole, the index plate 8 rotates, and the baffle plate 10 does not rotate. When the product arrives at these several mechanisms with the jig, the product falls into the corresponding Station;

[0025] Among them, the feeding mechanism 1 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com