Centering stacking method for stacking loaded sub-pallets onto mother pallets

A pallet and stacking technology, applied in the field of centering and stacking, can solve the problem of centering and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

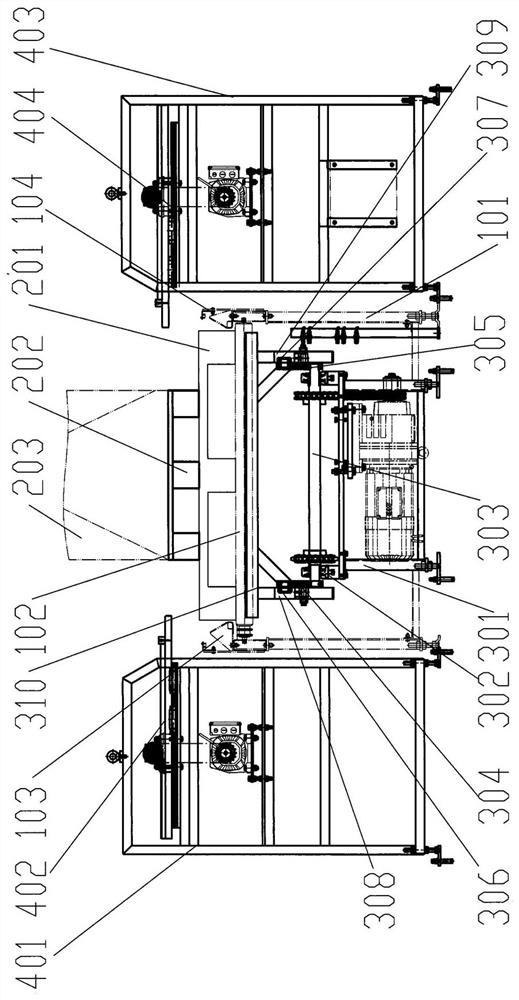

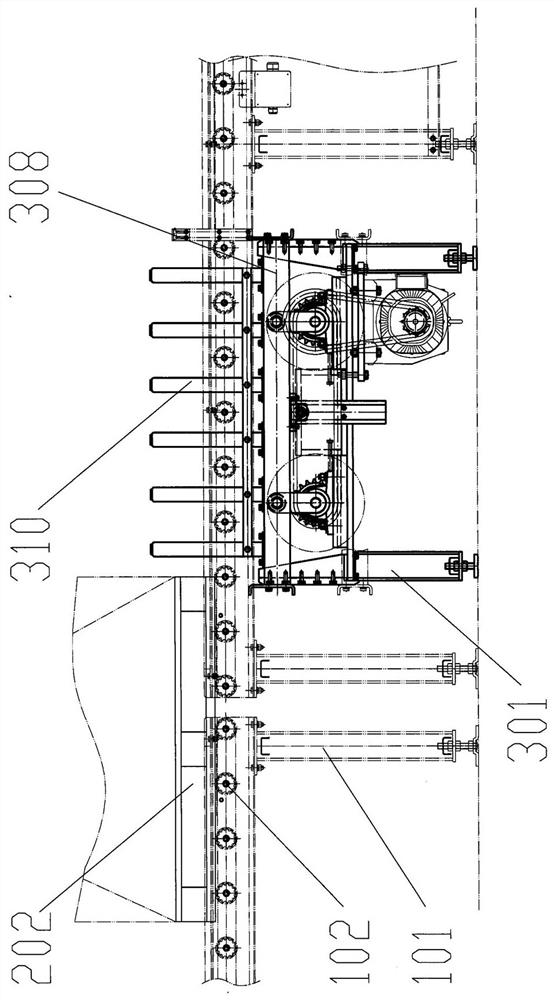

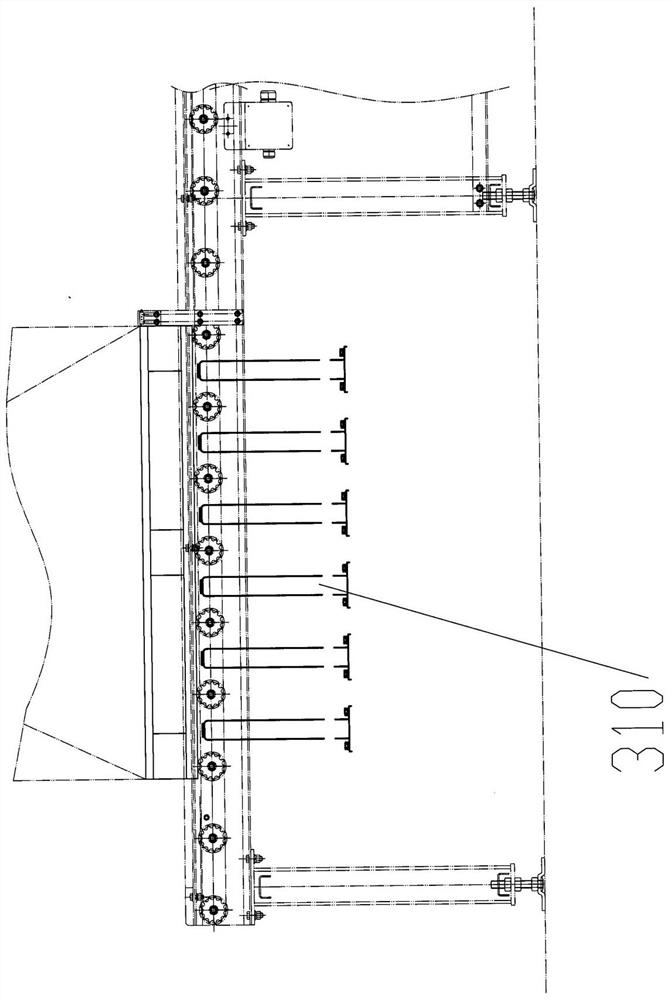

[0038] The present invention is described in detail below in conjunction with accompanying drawing:

[0039] A centering stacking device for stacking loaded sub-pallets onto a parent pallet, including a roller conveyor support 101, on which rollers 102 are arranged, and on the left and right sides of the rollers 102 Both sides are provided with a master tray limit guide plate 103, a sub-pallet 202 is conveyed on the roller 102, and the goods 203 are wound and fixed on the sub-pallet 202; In the stacking station, a pallet arrival detection switch 104 is provided on the roller conveyor bracket 101 of the mother-child pallet stacking station, and the pallet arrival detection switch 104 is electrically connected with the driving mechanism of the roller 102; Just below the roller 102 on the stacking station, a lifting device mounting frame 301 is provided, and a pallet lifting mechanism is arranged on the lifting device mounting frame 301. The lifting gantry 310 on the pallet lifti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap