Excavator control method and excavator

A control method and excavator technology, applied in engine control, electrical control, machine/engine, etc., can solve problems such as low work efficiency, delayed response action, high fuel consumption, etc., and achieve improved driving experience, stable and smooth operation, and improved The effect of response speed and motor coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

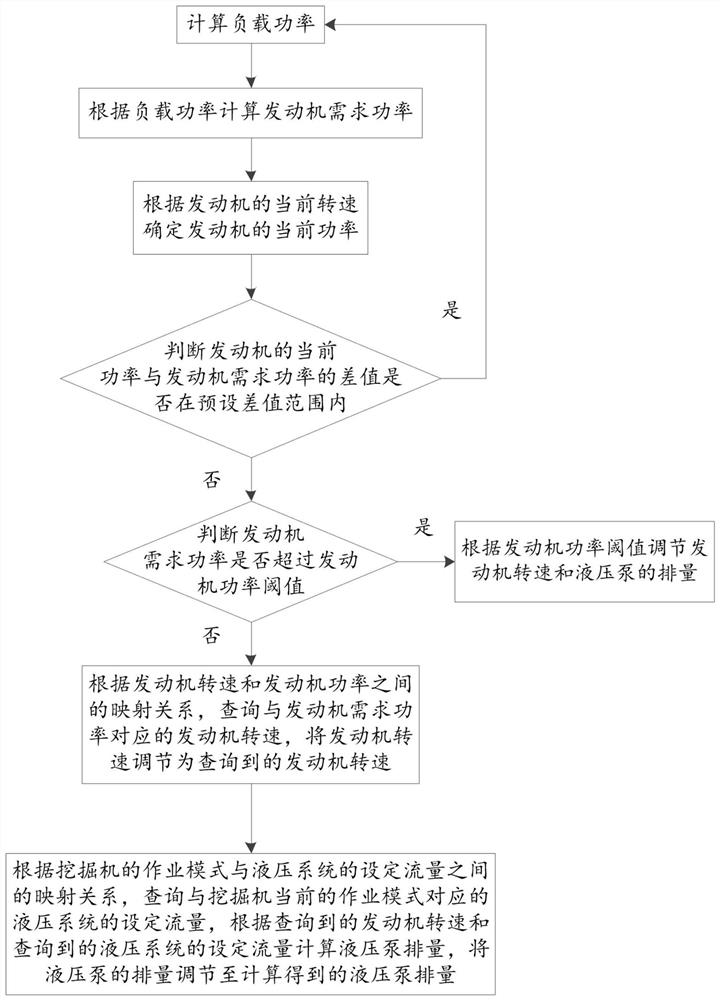

Examples

Embodiment 2

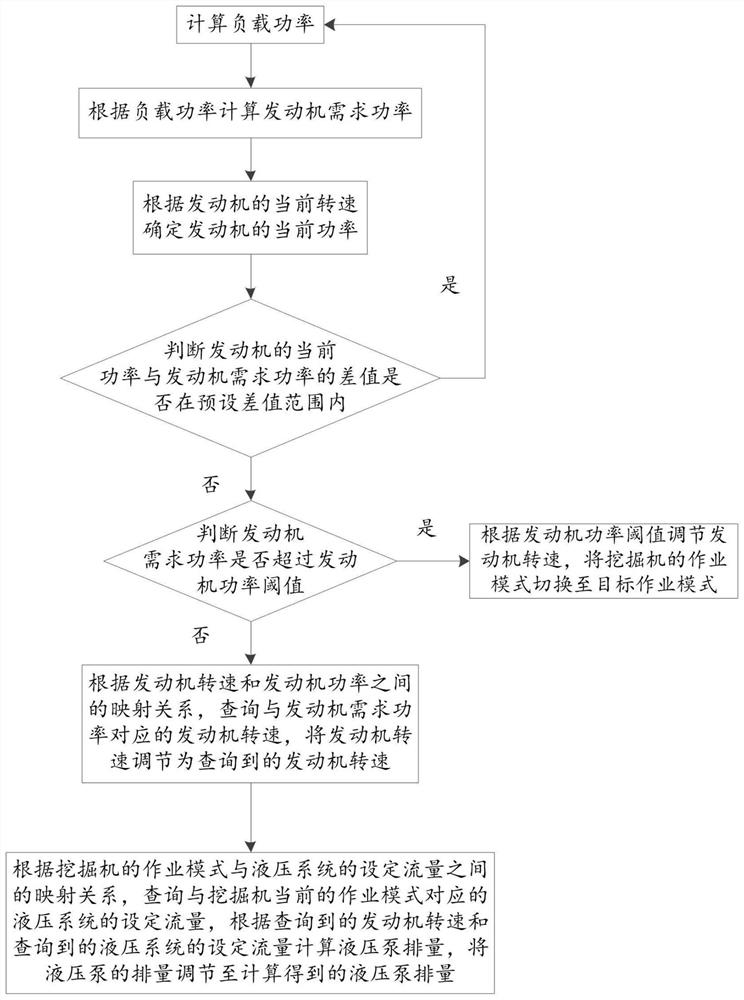

[0076] The difference between the embodiment and the embodiment is, such as figure 2 As shown, the difference between the current power of the engine and the engine demand power is not in the preset difference range, and when the engine demand power exceeds the engine power threshold, the current operation of the excavator is obtained according to the engine speed, and the current job of the excavator is acquired while the engine speed is adjusted. Mode, switch the excavator's job mode to the target job mode.

[0077] The above objective operation mode is a job mode that is not exceeding the engine power threshold and the gear position difference with the current job mode.

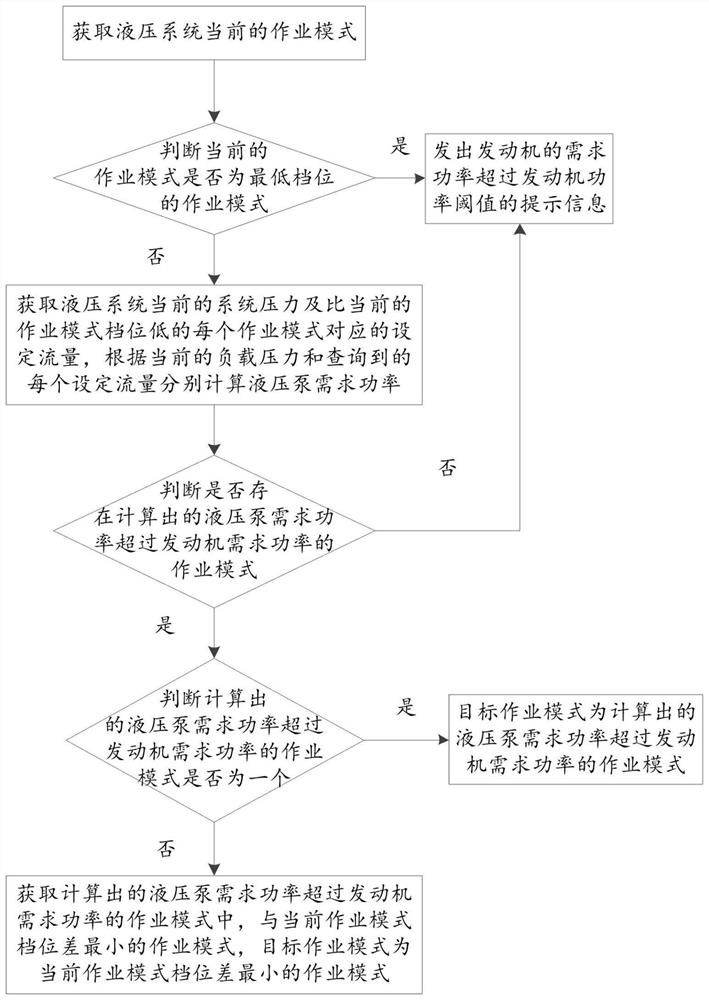

[0078] Specifically, such as image 3 As shown, the target job mode is obtained as follows:

[0079] S110, get the current operating mode of the hydraulic system;

[0080] S120, determine if the current job mode is a job mode of the minimum gear position. If so, the demand power of the engine exceeds the prompt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com