Modular manual ball valve

A manual ball valve, modular technology, applied in the direction of valve details, valve devices, engine components, etc., can solve problems such as troublesome operation, blockage of connection holes, etc., to reduce the difficulty of cleaning, facilitate multiple use, and improve smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

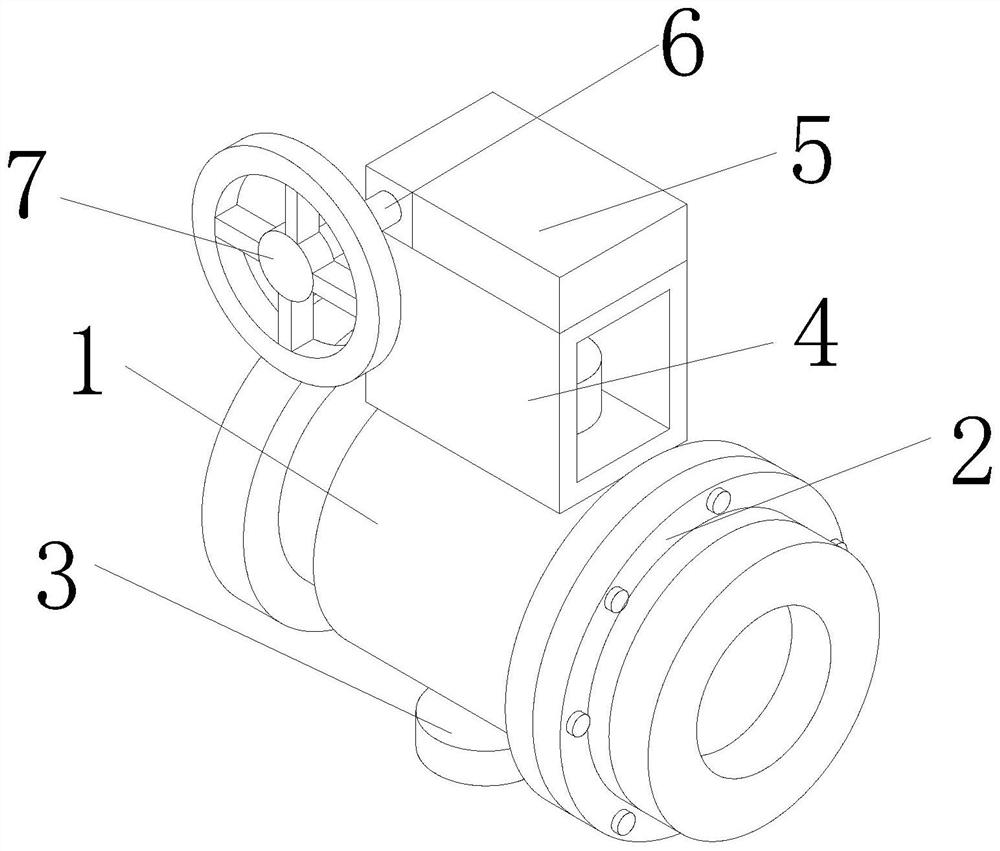

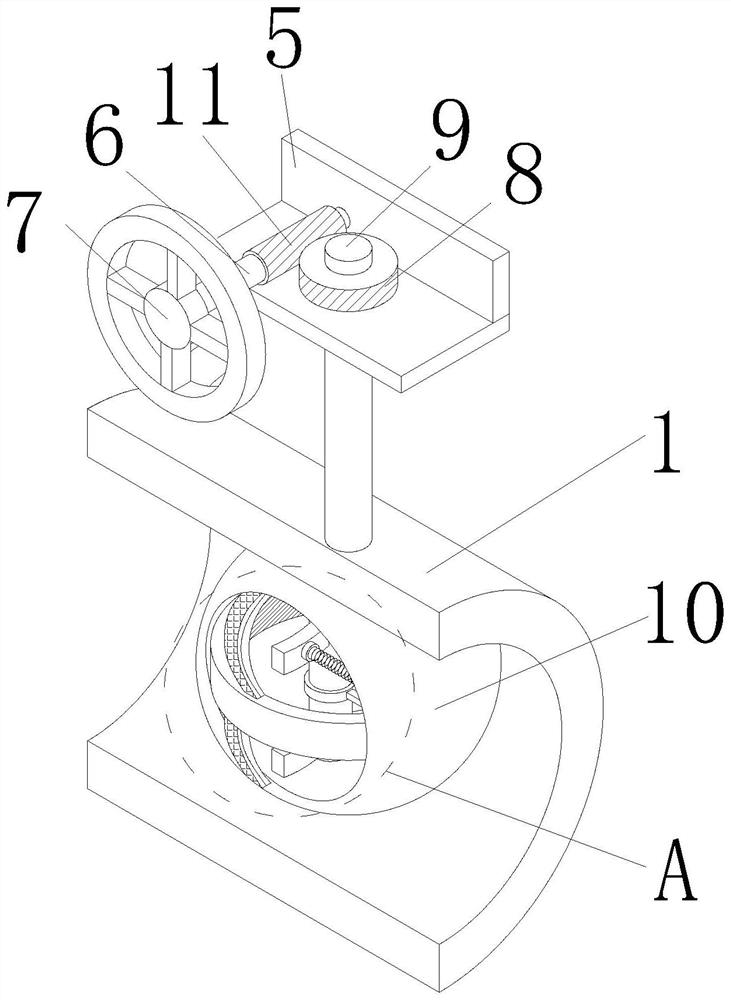

[0028] see Figure 1-6 , the present invention provides a technical solution: a modular manual ball valve includes a valve body 1, the left and right ends of the valve body 1 are provided with connecting flanges 2, when the device is used, it is connected to the water pipe through the connecting flange 2 , the bottom surface of the valve body 1 is fixedly connected with a bottom support 3, the top surface of the valve body 1 is fixedly connected with an internal hollow protective cover 4, the top surface of the protective cover 4 is fixedly connected with an internal hollow machine cover 5, the front of the machine cover 5 The surface is rotatably connected with a transmission rod 6, the rear end of the transmission rod 6 runs through the hood 5 and extends to the inside of the hood 5, the front end of the transmission rod 6 is fixedly connected with a hand wheel 7, when using the device, by turning the hand wheel 7 drives the transmission rod 6 to rotate.

[0029] Further, t...

Embodiment 2

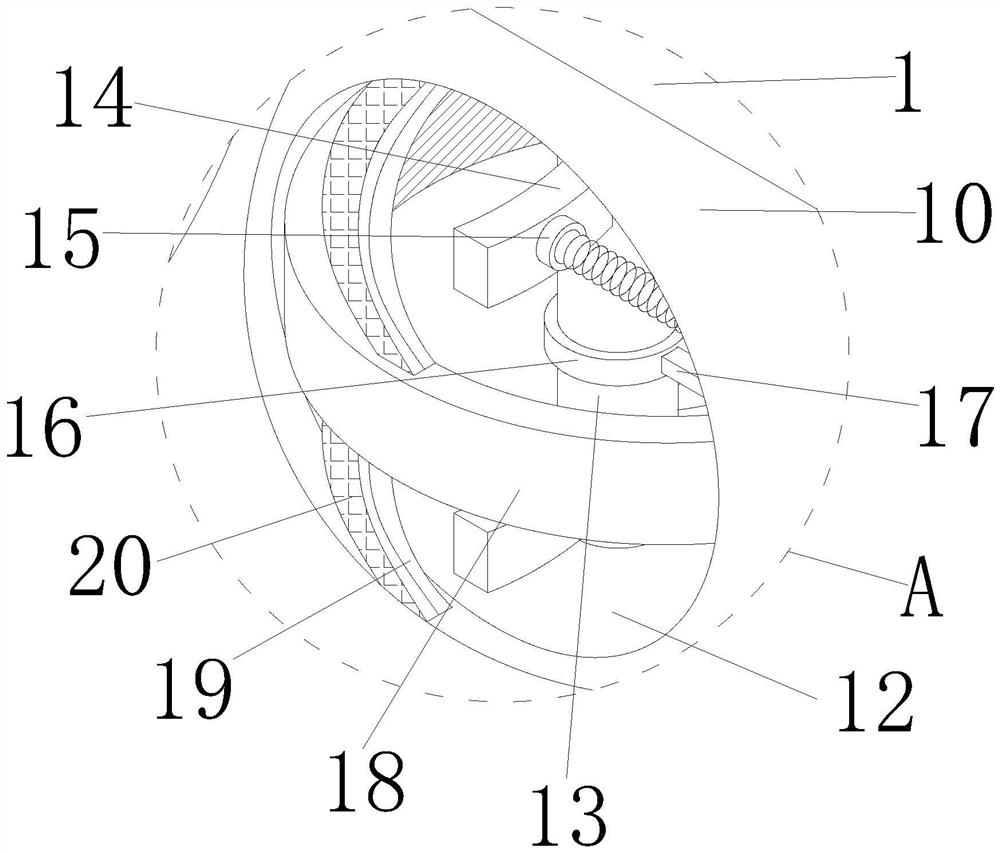

[0033] see Figure 1-6 , on the basis of Embodiment 1, the inside of the valve body 1 is provided with a swing device, the swing device includes a rotating shaft 13, the rotating shaft 13 is connected to the bottom surface of the inner wall of the water hole 12 in rotation, and the front surface of the rotating shaft 13 is fixedly connected with a guide The deflector 14 is fixedly connected with a spring 15 on the left surface of the deflector 14 , and the end of the spring 15 away from the deflector 14 is fixedly connected with the inner wall of the water hole 12 .

[0034] Further, when the device is used, when the water flow passes through the water hole 12, the driving force of the water flow is used to push the deflector 14 to rotate, and the rotation of the deflector 14 drives the rotation shaft 13 to rotate, and the deflector 14 is supported by the spring when it rotates. The limitation of 15 makes the deflector 14 unable to rotate substantially. After the water flow pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com