Automatic vibration-free self-compacting uniform blanking device for prestressed concrete cylinder pipe

A technology of concrete pipe and prestressed steel, applied in auxiliary forming equipment, supply device, ceramic forming machine, etc., can solve the problem of uneven blanking and achieve the effect of uniform blanking distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

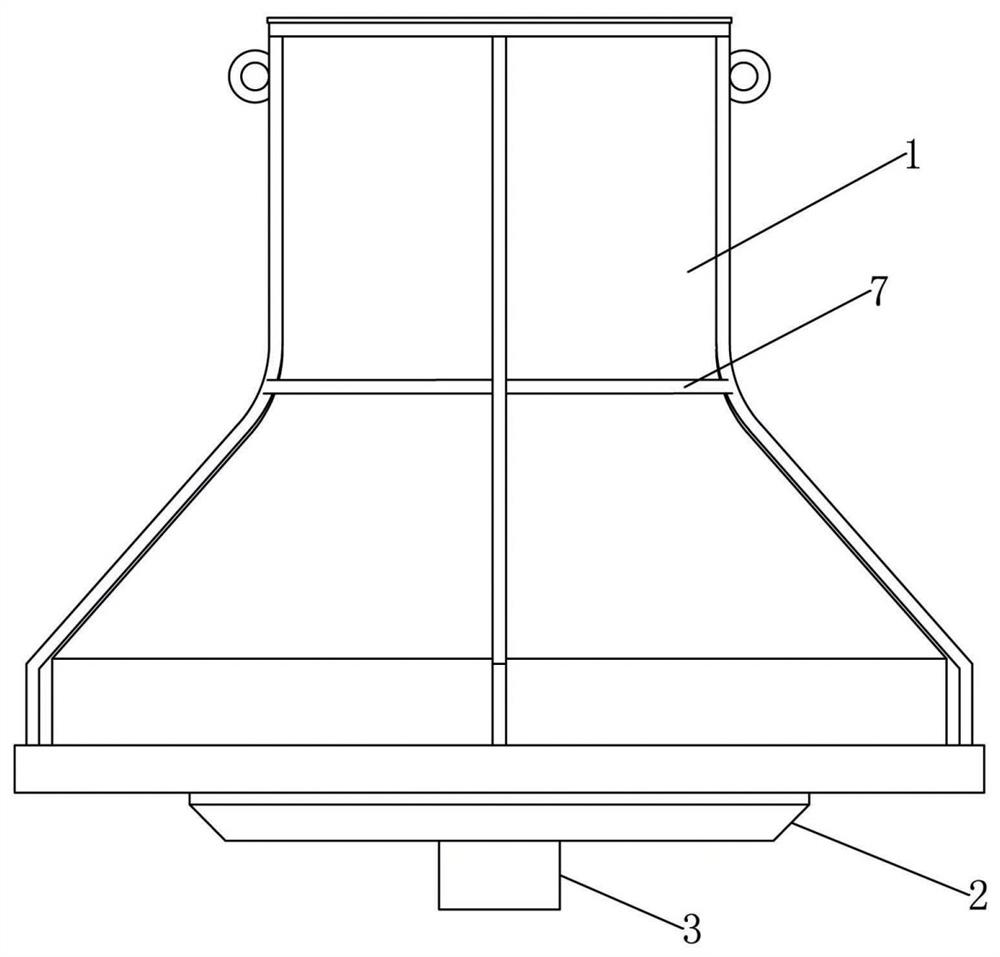

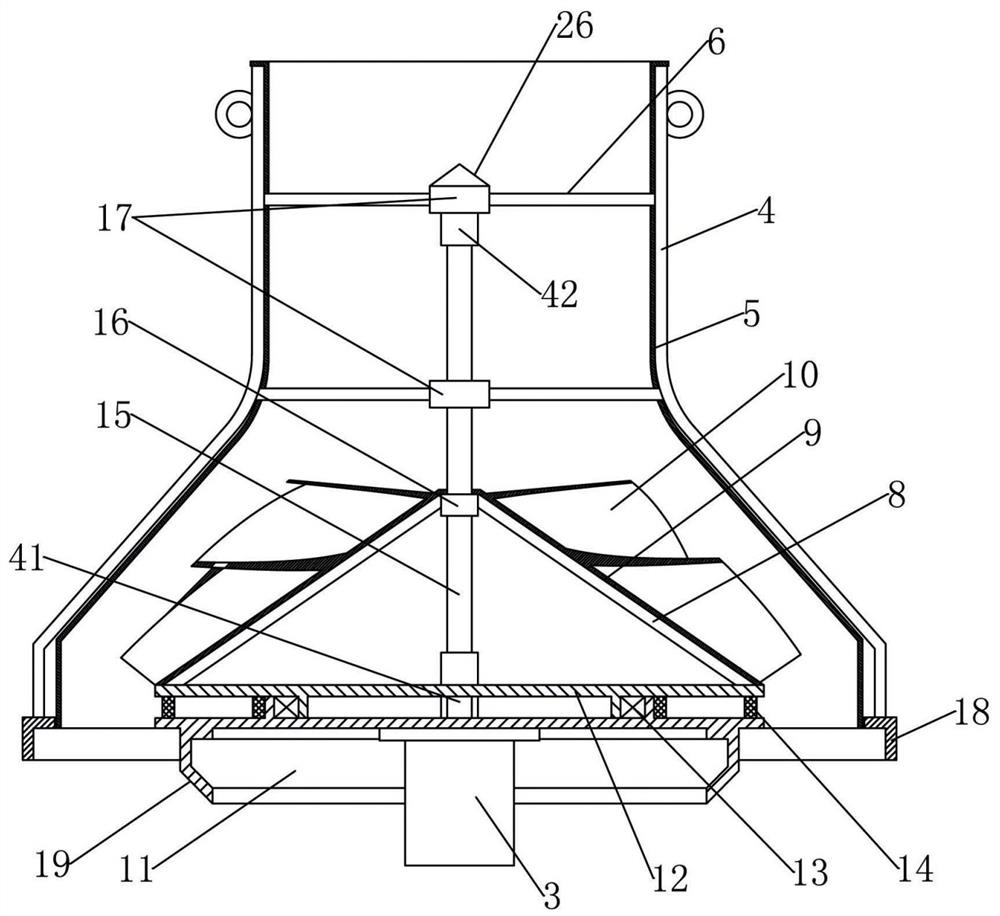

[0047] Embodiment 1: a kind of as figure 1 The device shown is used in the preparation process of prestressed steel cylinder concrete pipes to realize the uniform feeding of automatic vibration-free self-compacting concrete. This device is aimed at the current preparation process of prestressed steel cylinder concrete pipes. , but there are technical difficulties in the vibrating rod penetrating into the pipe mold gap, and the cost is high when using self-compacting concrete, and the self-compacting concrete must also consider the problem of uniform feeding. The existing feeding mechanism only uses the conical cover to disperse the concrete, relying on the concrete The self-weight falls naturally, and the reliability of the uniformity of the fall is not strong. This embodiment is designed to solve this problem.

[0048] One implementation of the device looks like figure 1 As shown, it can be seen that it includes two main components: an outer cone housing assembly 1 and an in...

Embodiment 2

[0056]In the application of this embodiment, the device is hoisted directly above the mold barrel by hoisting equipment, and then lowered down to connect with the inner and outer barrels of the mold respectively, that is, the bottom of the outer frame is supported on the upper edge of the outer mold barrel, and the base is supported on the inner mold The upper edge of the tube. There are converging chamfers 19 on the periphery of the base 11, which can be centered with the inner mold barrel and drop down, and then the annular seat 18 is sleeved on the upper side of the outer mold barrel.

[0057] A pressure sensor is arranged below the annular seat 18, the inner cone cover body assembly 2 falls first, and the outer cone cover body assembly 1 falls behind, and when the pressure sensor at the bottom of the outer cone cover body assembly 1 has a pressure signal, the pressure signal is sent to The signal input terminal of the controller is controlled by the controller to drive the...

Embodiment 3

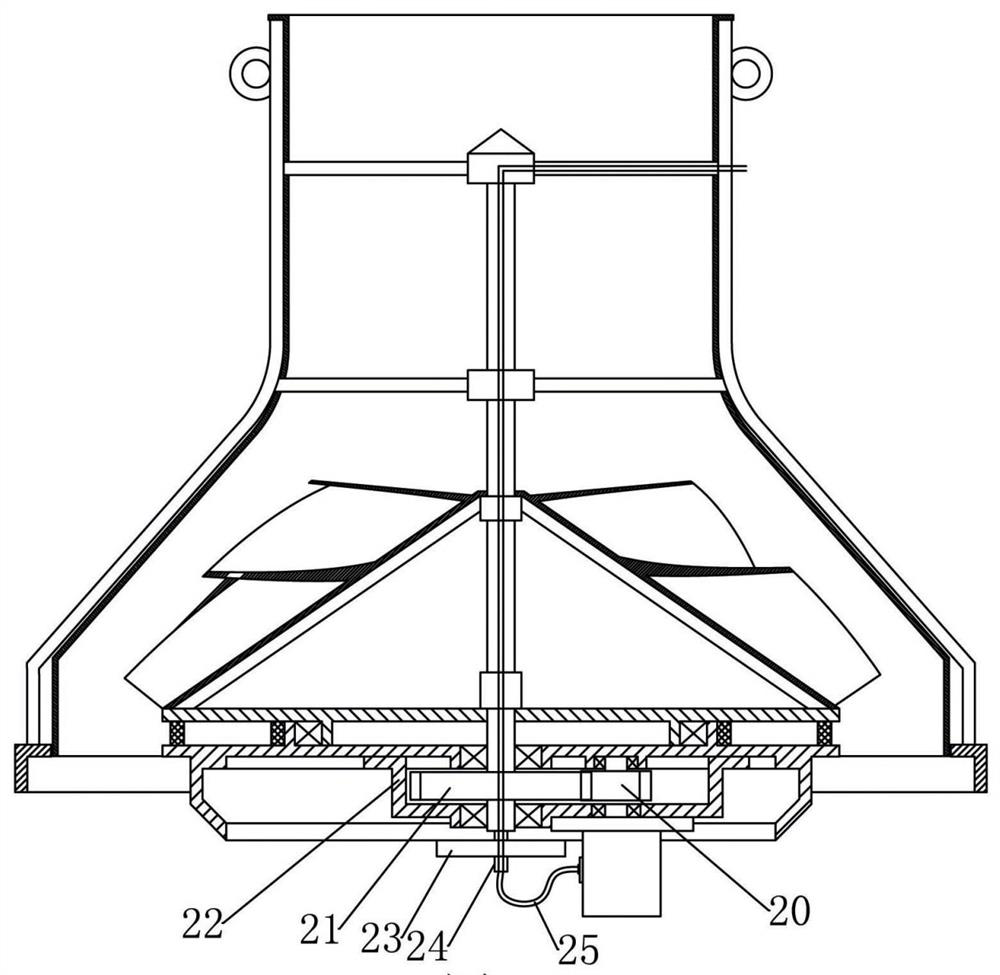

[0062] Embodiment 3: Another vibration-free self-compacting uniform feeding device for prestressed steel cylinder concrete pipes, such as Figure 9 shown (or refer to Figure 8 ), the two main components of the device are the outer cone cover assembly 1 and the inner cone cover assembly 2. from Figure 9 It can be seen that the outer cone housing assembly 1 and the inner cone housing assembly 2 are independent of each other, but are connected together through a central fixed shaft. Different from Embodiment 1, the drive motor 3 of this embodiment drives the outer cover to rotate at a uniform speed.

[0063] Figure 9 It can be seen from the figure that the outer cone cover assembly 1 includes an outer frame 4 and an inner outer cover body 5, both of which are fixed together, the outer cover body includes an upper cylindrical section and a lower conical section, the upper end of the outer cover body is an inlet, and the lower end is an outlet , the outer cover body is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com