Spraying type circulating pickling equipment for maintaining steel wire rope

A cyclic pickling and spray type technology, which is applied in the field of spray type cyclic pickling equipment for wire rope maintenance, can solve the problem of inconvenient device automatic driving cycle washing, inconvenient pickling solution anti-splash treatment, and inconvenient device dustproof protection treatment and other problems, to achieve the effect of improving dustproof protection, convenient and efficient circulation cleaning, and simple and efficient device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

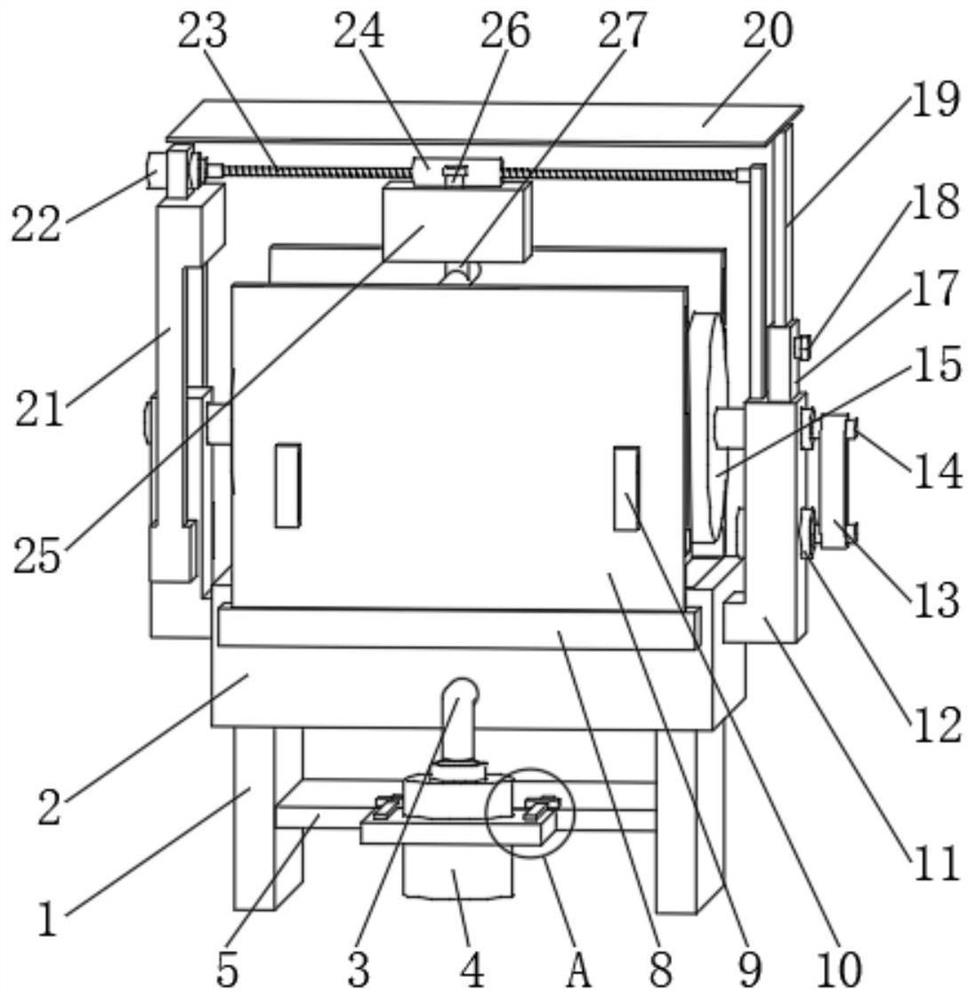

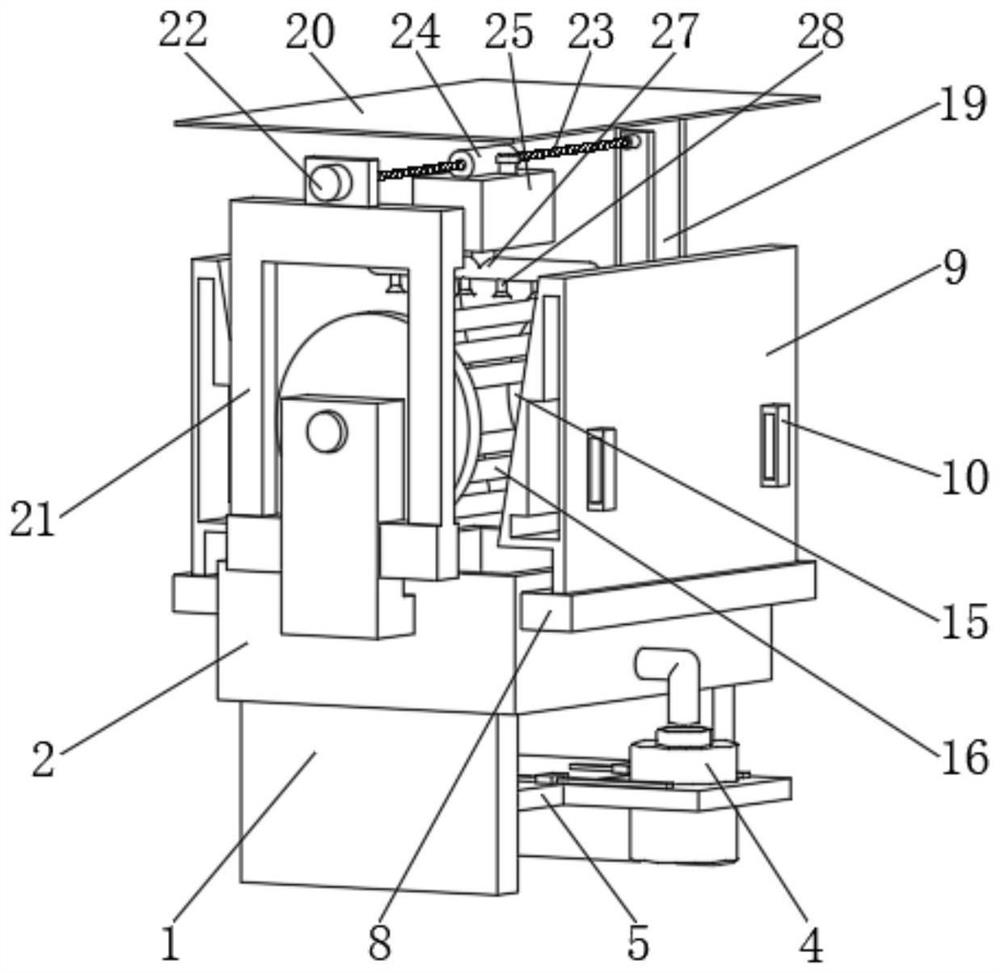

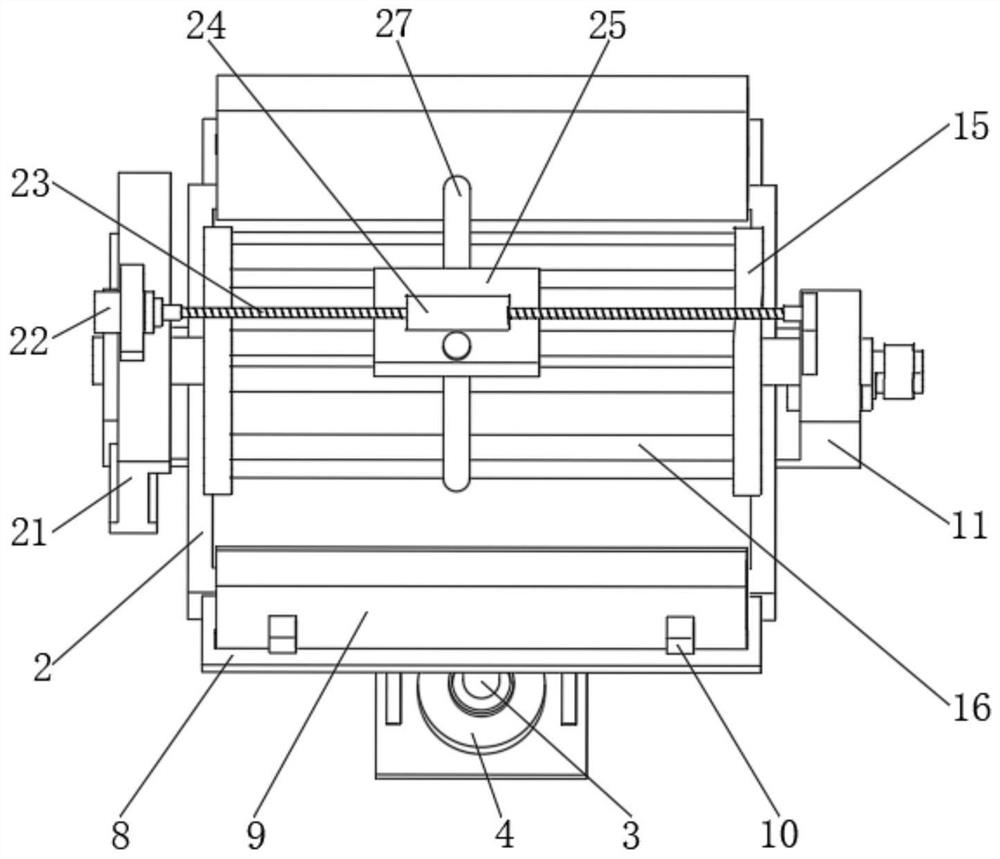

[0027] see Figure 1-5 As shown, a spray type circulating pickling equipment for steel wire rope maintenance includes a support foot 1, a first support frame 11 and a second support frame 21, a waste liquid tank 2 is arranged on the top of the support foot 1, and the waste liquid tank 2 The outer wall of the waste liquid pipe 3 is provided with a collection tank 4, and the end of the collection tank 4 is provided with a partition plate 5, and the side of the collection tank 4 is provided with a connecting plate 6, and the connecting plate 6 The outer side of the waste liquid tank 2 is provided with a fixed sleeve 7, the outer wall of the waste liquid tank 2 is provided with a fixed seat 8, and the inner side of the fixed seat 8 is provided with a splash guard 9, and the outer wall of the splash guard 9 is provided with a fixed handle 10.

[0028] The collection tank 4 forms a snap-fit structure through the connecting plate 6 and the fixed sleeve 7, and a pair of the fixed sl...

Embodiment 2

[0031] see Figure 1-4 As shown, compared with Example 1, as another embodiment of the present invention, the first support frame 11 is arranged on one side of the waste liquid tank 2, and the inner side of the first support frame 11 is equipped with a servo motor 12, and the servo motor 12 The end of the belt 13 is connected with a belt 13, and the end of the belt 13 is provided with a connecting shaft 14, the end of the connecting shaft 14 is provided with a connecting disc 15, and the side of the connecting disc 15 is provided with a limit rod 16, the first support frame 11 The top of the hollow cover 17 is provided with a hollow cover 17, and the outer wall of the hollow cover 17 is provided with a fixing nail 18, the inner side of the hollow cover 17 is provided with an inner panel 19, and the top of the inner panel 19 is provided with a dust shield 20, and the second support The frame 21 is arranged on the other side of the waste liquid tank 2, and a drive motor 22 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com