Modified carbon nanocone functionalized needle tip and preparation method thereof

A carbon nanocone, nanocone technology, applied in nanotechnology, nanotechnology, nanotechnology for information processing, etc., can solve the problems of reducing the utilization rate of carbon nanocones, improve the field enhancement effect, and avoid the damage of the needle tip structure. Even failure, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

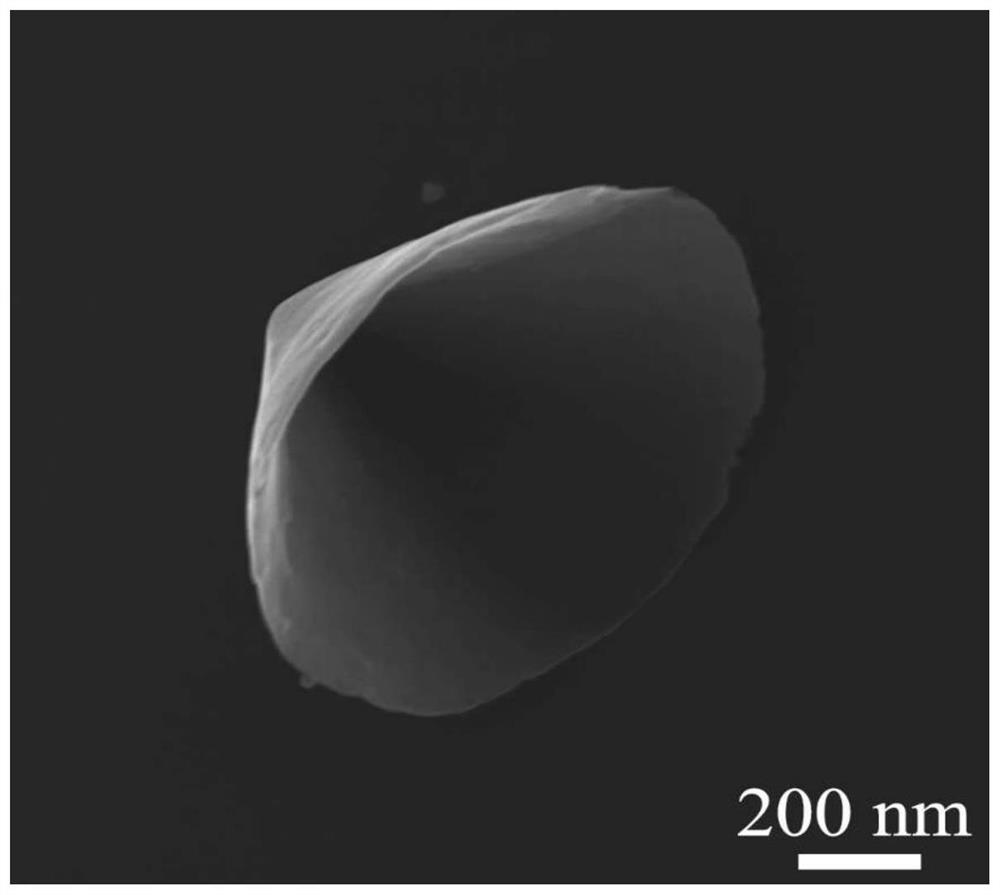

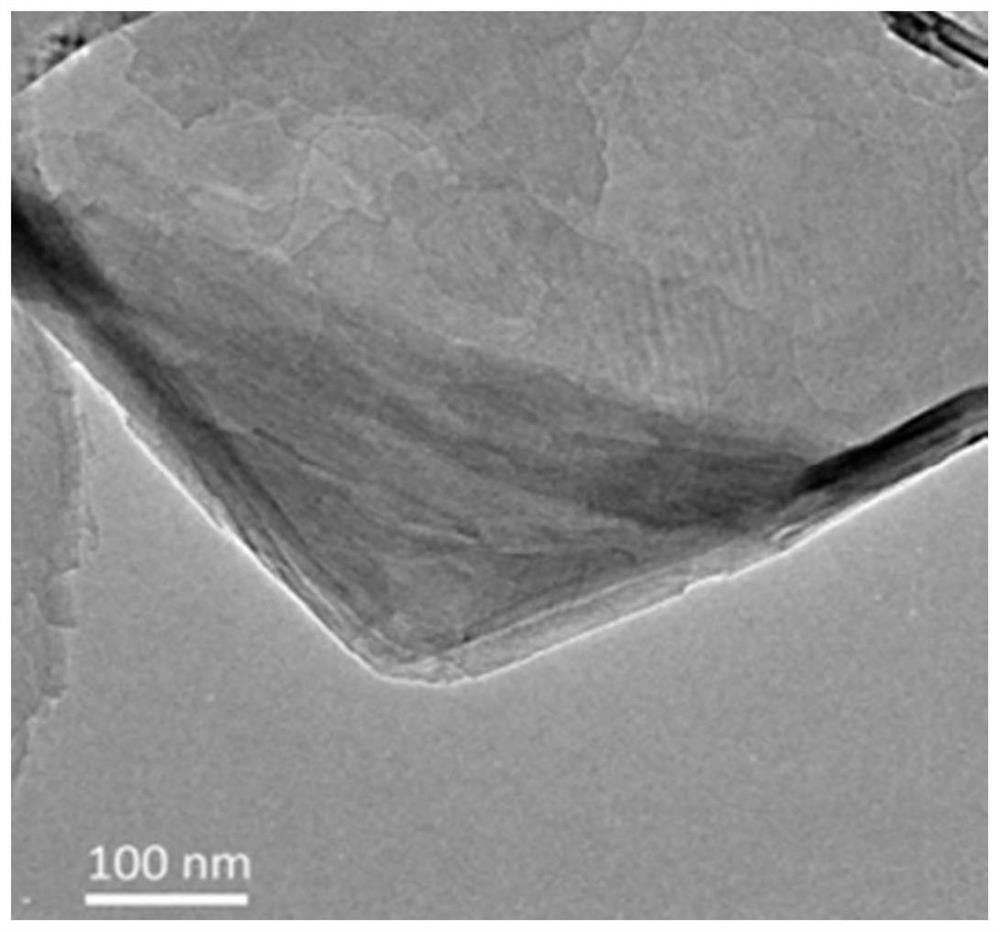

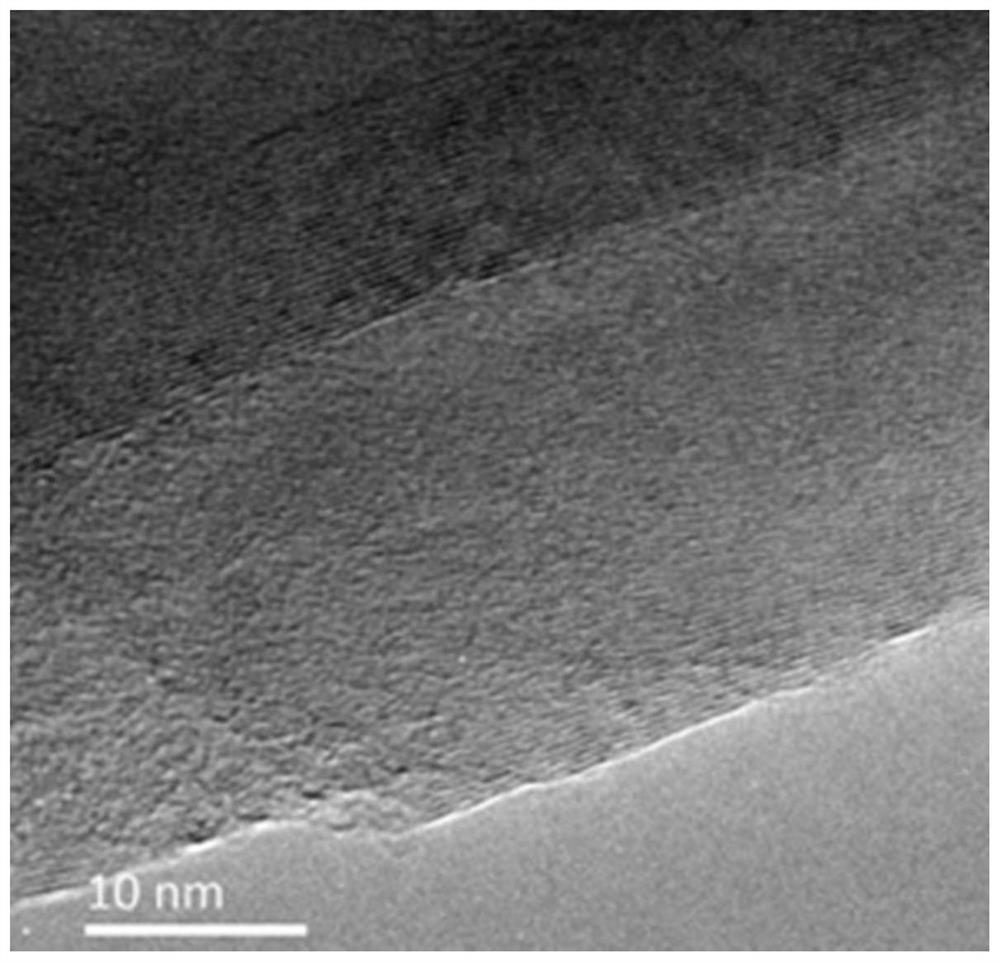

[0040] see Figure 1-4 , this embodiment provides a modified carbon nanocone functionalized tip, the base material of which is metal tungsten, and the front end is modified by the modified carbon nanocone. The modified carbon nanocone is a product obtained by etching the carbon nanocone. Its tip and tail are etched into a stepped shape, the tip is sharp, the surface is clean and free of impurities, and there are dangling bonds on the surface of the tip. The tail of the modified carbon nanocone forms a covalent bond interface connection with the base of the needle tip, and the orientation of the tip is consistent with the orientation of the central axis of the needle tip. figure 1 It is the scanning electron microscope (SEM) photo of the modified carbon nanocone obtained in the present embodiment, and it can be observed that there is a slight etching phenomenon in the tip and tail of the modified carbon nanocone by scanning data; figure 2 It is the transmission electron micro...

Embodiment 2

[0046] see Figure 5-9 , this embodiment provides a modified carbon nanocone functionalized tip, the base material of which is metal cobalt, and the front end is modified by modified carbon nanocone. The modified carbon nanocone is a product obtained by etching the carbon nanocone. Its tip and tail are etched into a stepped shape, the tip is sharp, the surface is clean and free of impurities, and there are dangling bonds on the surface of the tip. The tail of the modified carbon nanocone forms a covalent bond interface connection with the base of the needle tip, and the orientation of the tip is consistent with the orientation of the central axis of the needle tip.

[0047] Figure 5 It is the SEM photo of the modified carbon nanocone obtained in this embodiment. It can be visually observed through the scanning data that there is an etching phenomenon at the tip and tail of the modified carbon nanocone. Image 6 It is a TEM photo of the modified carbon nanocone tip obtained ...

Embodiment 3

[0053] see Figure 10-11 , this embodiment provides a modified carbon nanocone functionalized needle tip, the base material of which is metal nickel, and the front end is modified by the modified carbon nanocone. The modified carbon nanocone is a product obtained by etching the carbon nanocone. Its tip and tail are etched into a stepped shape, the tip is sharp, the surface is clean and free of impurities, and there are dangling bonds on the surface of the tip. The tail of the modified carbon nanocone forms a covalent bond interface connection with the base of the needle tip, and the orientation of the tip is consistent with the orientation of the central axis of the needle tip.

[0054] Figure 10 It is the SEM photo of the modified carbon nanocone obtained in the present embodiment, and it can be visually observed that the tip of the modified carbon nanocone is completely etched by scanning data, which is open, and the tail is also severely etched; Figure 11 It is an HRTEM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com