Opening and closing device of cone crusher

A technology of cone crusher and opening and closing device, which is applied in grain processing and other directions, can solve the problems of inability to guarantee product grain shape, easy wear of seals, loose adjustment ring, etc., so as to maintain production effect, reduce looseness and maintain high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] The embodiment of the invention discloses an opening and closing device for a cone crusher.

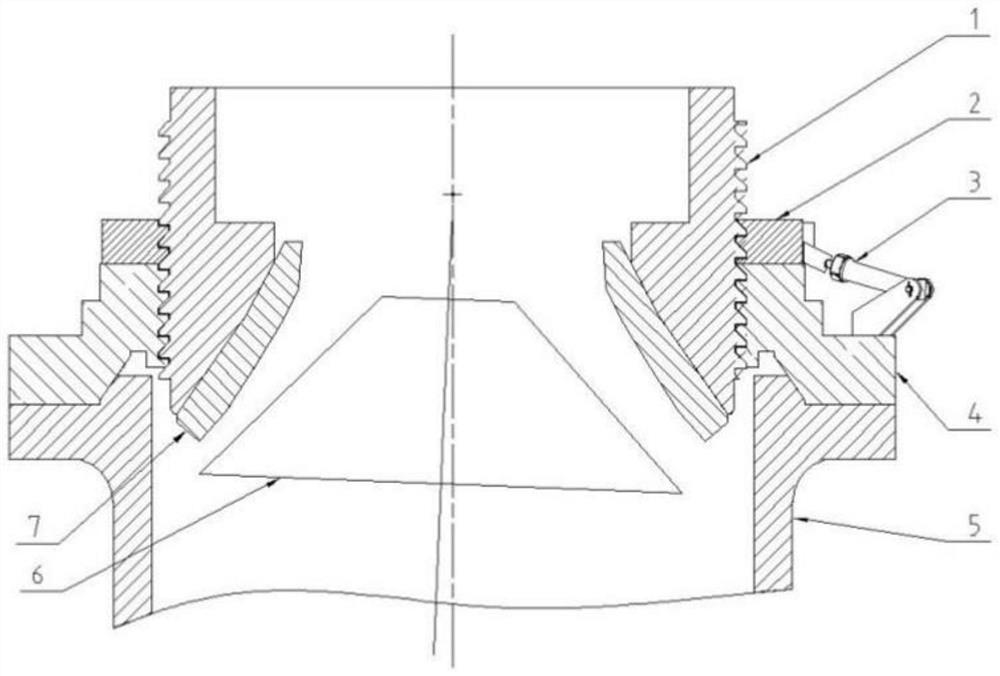

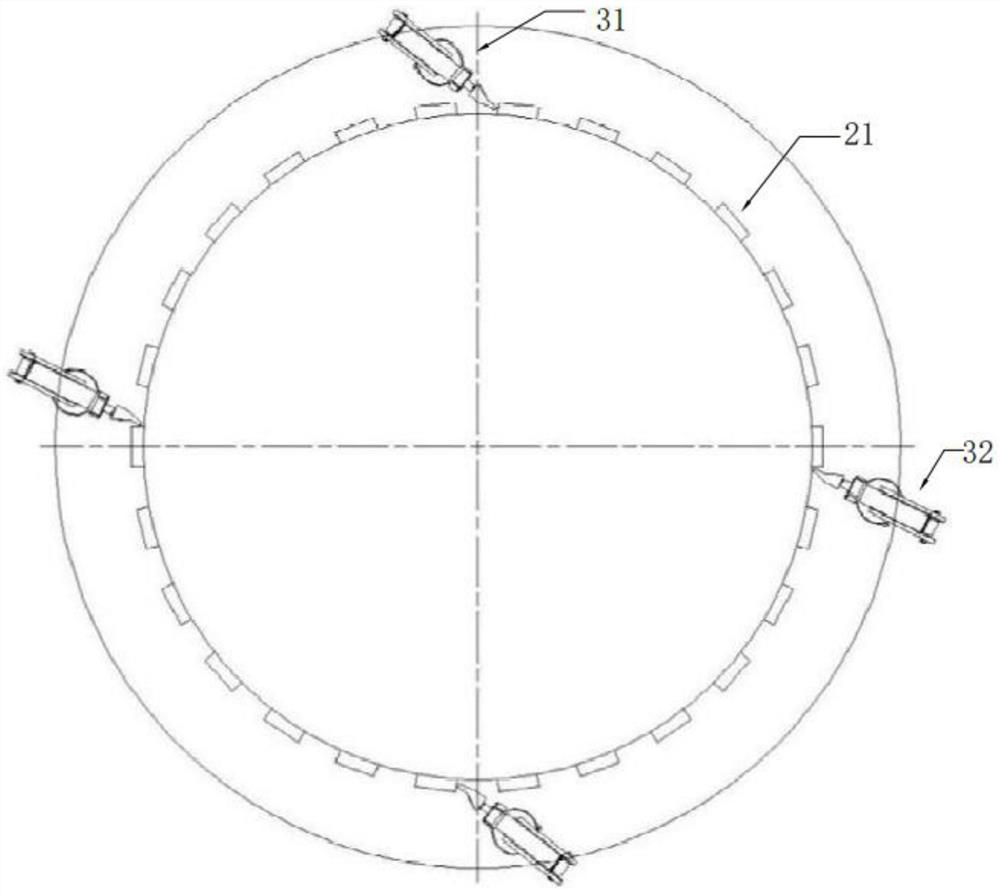

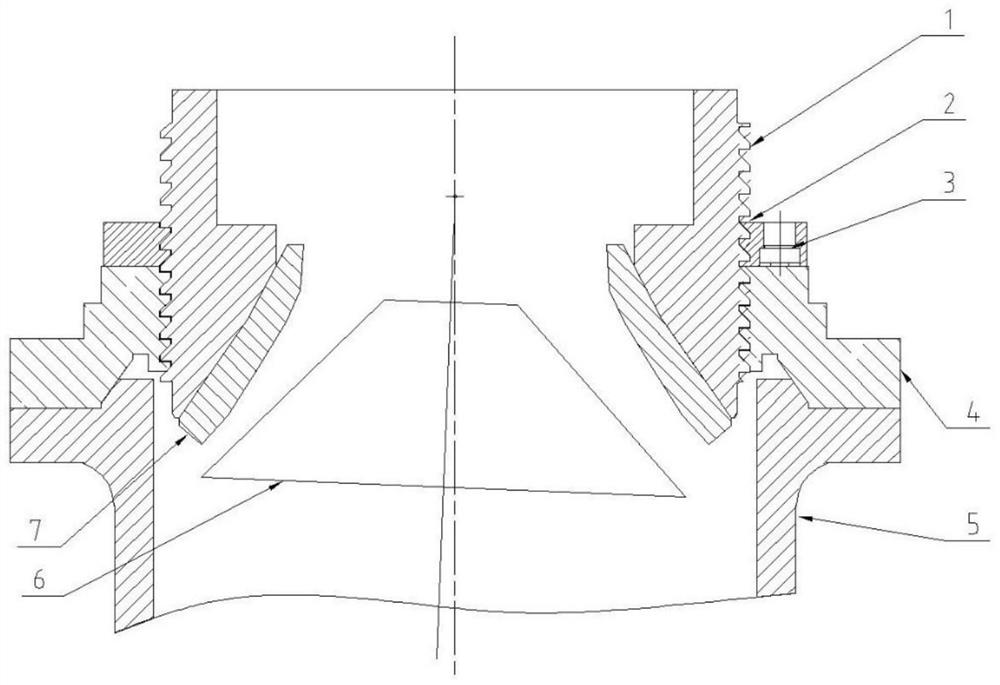

[0018] refer to figure 1 with figure 2 , a cone crusher opening and closing device, including a fixed cone, including an adjustment ring 1, a lock nut 2 and a support sleeve 4, and the lock nut 2, support sleeve 4 and frame 5 are arranged coaxially from top to bottom, The fixed cone is installed on the inner wall of the adjusting ring 1, and the adjusting ring 1 is provided with external threads, and the supporting sleeve 4 and the lock nut 2 are both screwed to the adjusting ring 1, and the supporting sleeve 4 is fixed with two A first hydraulic push cylinder 31, the piston rods of the two first hydraulic push cylinders 31 are opposite and arranged in parallel, the first hydraulic push cylinder 31 is located at both ends of the circumferential diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com