Heavy metal contaminated soil remediation device and remediation method thereof

A technology for polluted soil and heavy metals, applied in the field of soil remediation, can solve the problems of difficult soil discharge and decreased soil remediation process efficiency, and achieve the effects of fine remediation work, compact structure and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

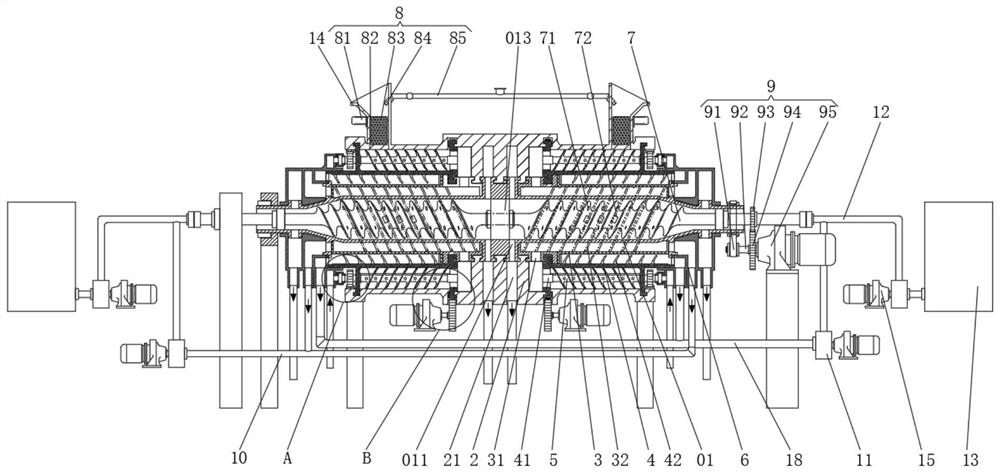

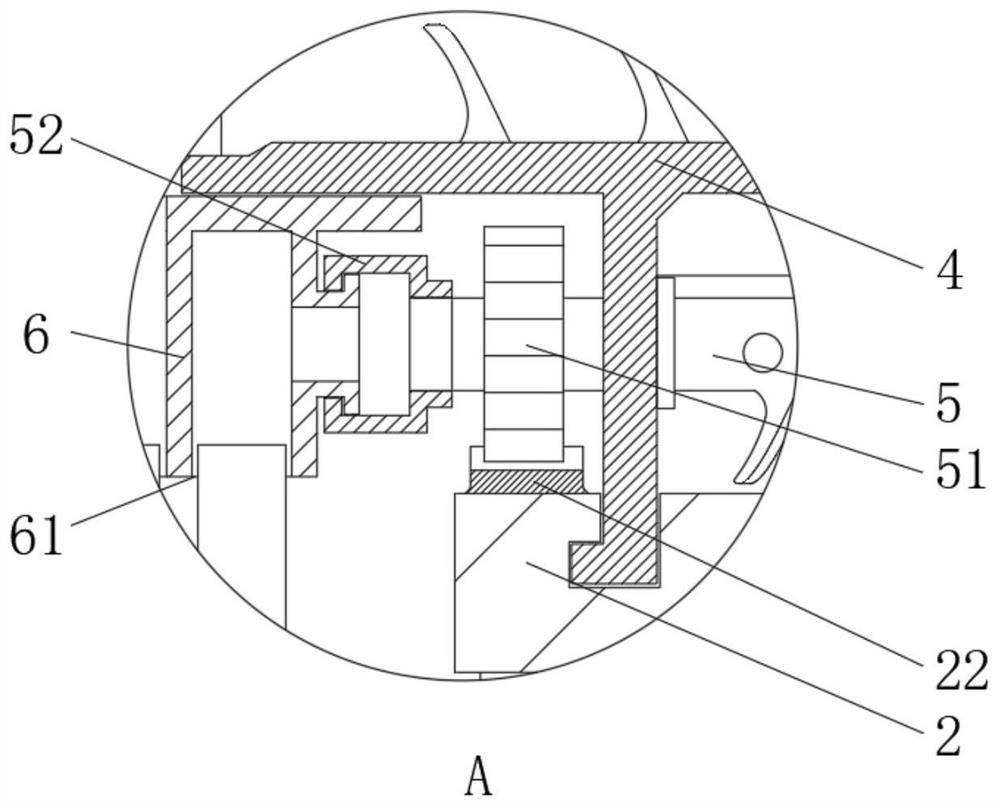

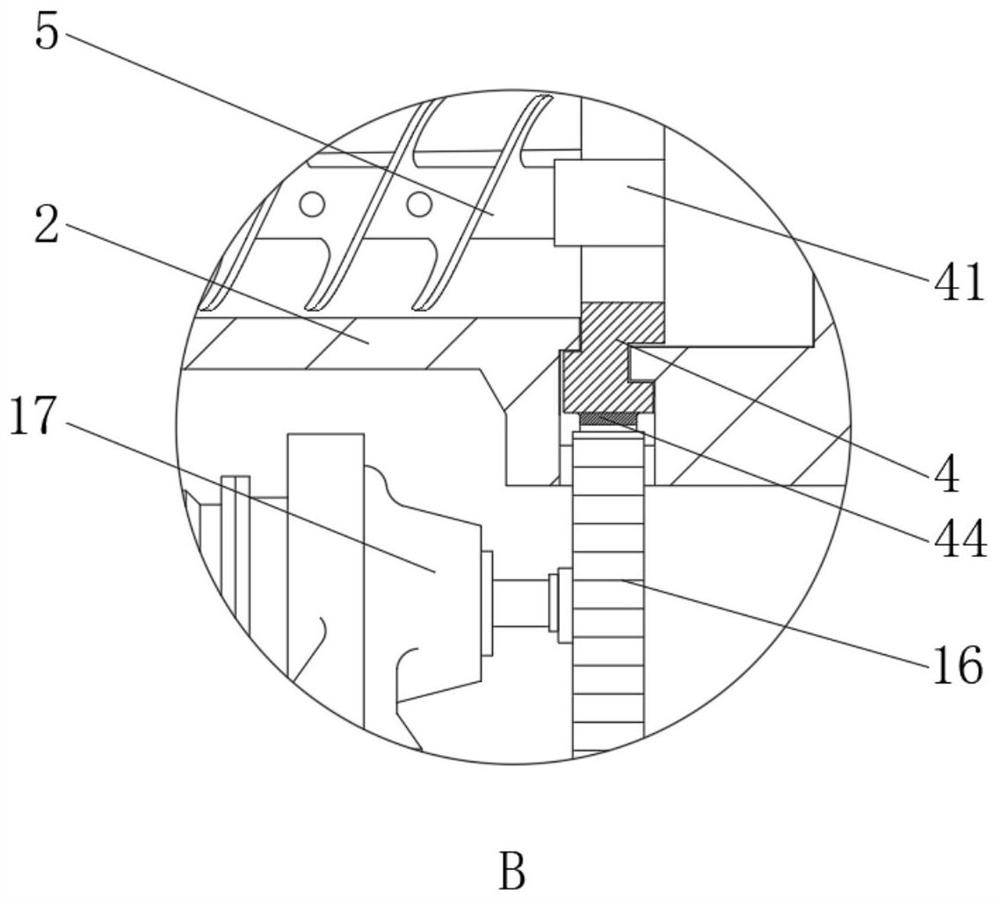

[0065] Such as Figure 1-Figure 17 As shown, a repairing device for heavy metal-contaminated soil includes a central drum 01, a hollow screw rod 7 is arranged inside the central drum 01, and a screening cylinder 3 is arranged on the outer surface of the central drum 01, and the screening cylinder 3 and the central drum 01 is fixedly connected, the inner wall of the screening cylinder 3 is provided with a first helical blade 32, the outer rotating sleeve of the screening cylinder 3 is provided with a sandwich drum 4, and the inner wall of the interlayer drum 4 is provided with a second helical blade 42, and the interlayer rotary There is an external fixed cylinder 2 on the outside of the cylinder 4, and the interlayer drum 4 is rotationally connected with the screening cylinder 3 and the external fixed cylinder 2. A stirring rod 5 is arranged between the external fixed cylinder 2 and the interlayer rotary cylinder 4, and the external fixed cylinder 2 and the cavity between the ...

Embodiment 2

[0084] Such as Figure 1-Figure 17 As shown, a repairing device for heavy metal-contaminated soil includes a central drum 01, a hollow screw rod 7 is arranged inside the central drum 01, and a screening cylinder 3 is provided outside the central drum 01, and a screening cylinder 3 is provided on the inner wall of the screening cylinder 3. There is a first helical blade 32, the outer rotating sleeve of the screening cylinder 3 is provided with an interlayer drum 4, the inner wall of the interlayer drum 4 is provided with a second helical blade 42, and the outer sleeve of the interlayer drum 4 is provided with an outer fixed cylinder 2, which is fixed outside. A stirring rod 5 is arranged between the drum 2 and the interlayer drum 4, and the cavity between the outer fixed drum 2 and the interlayer drum 4 communicates with the cavity between the screening drum 3 and the central drum 01;

[0085] The two ends of the central drum 01 are symmetrically provided with two coaxially con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com