A kind of soft magnetic high-silicon steel ultra-thin strip and its preparation method

A high-silicon steel, ultra-thin strip technology, applied in solid-state diffusion coating, coating, and devices for coating liquid on the surface, etc. problem, to achieve the effect of excellent ductility, good mechanical properties, high magnetic induction iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

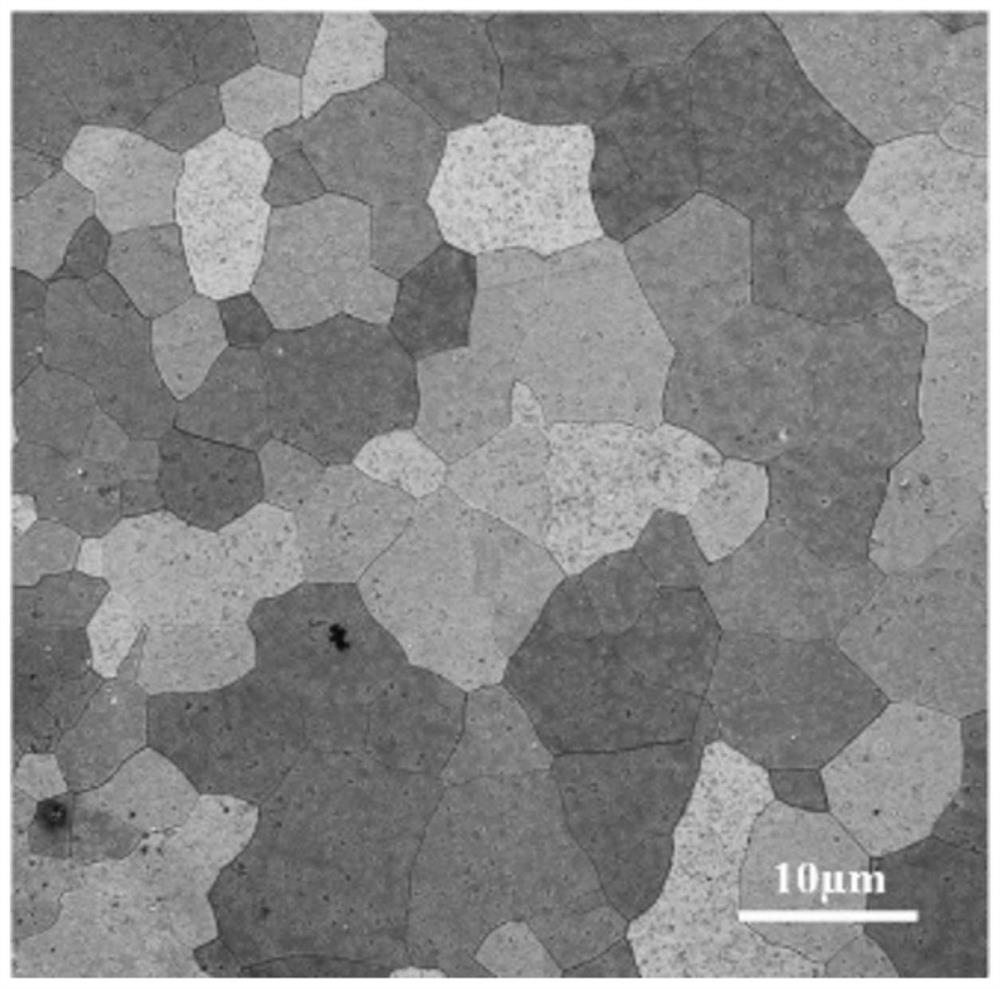

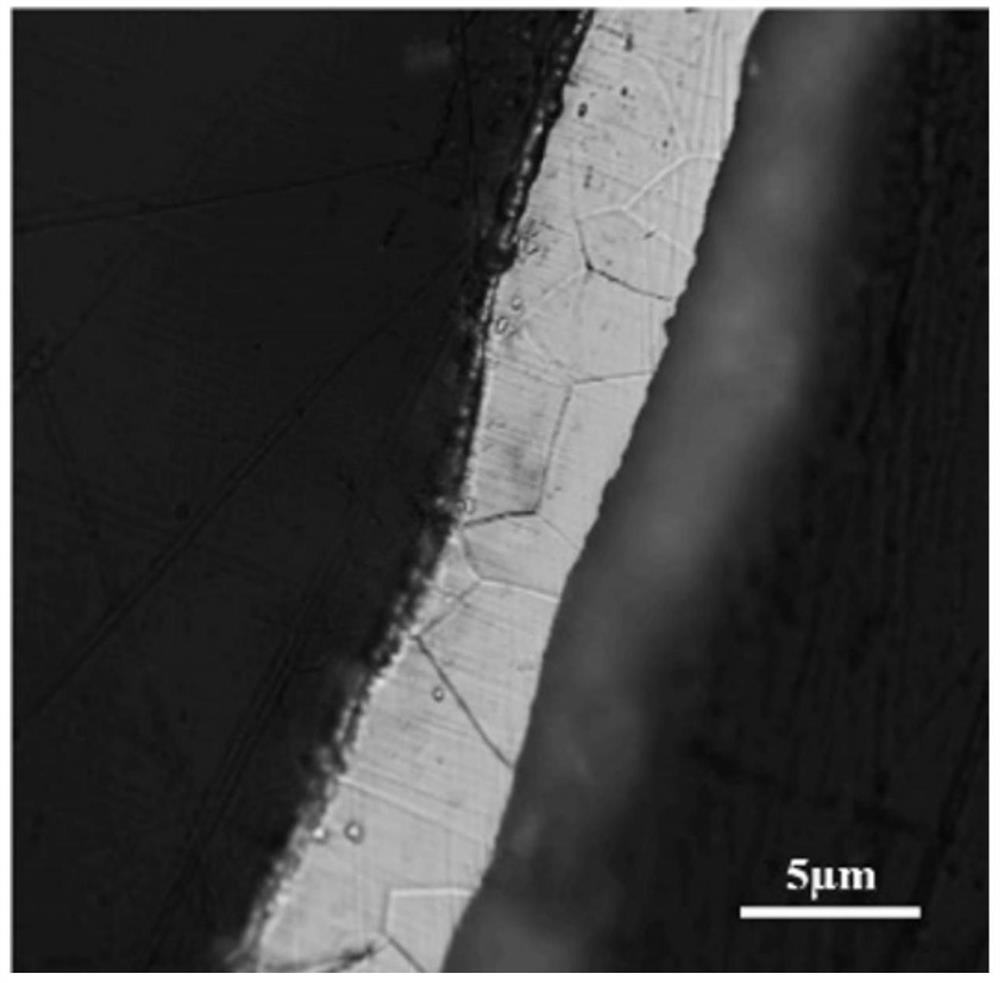

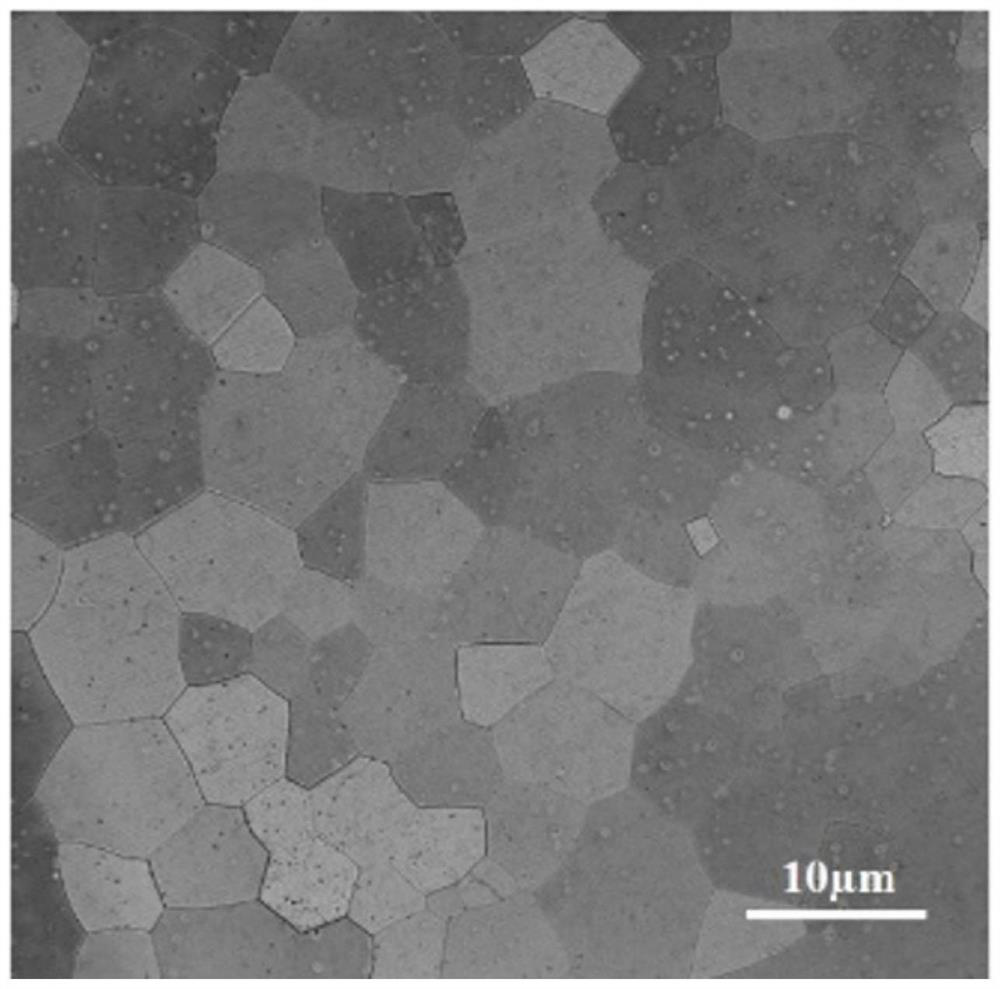

Image

Examples

Embodiment 1

[0035] A preparation method of a soft magnetic high silicon steel ultra-thin strip, comprising the following steps:

[0036] a. Take high-silicon steel parent alloy, niobium-iron alloy and cobalt-iron-silicon alloy as raw materials for preparing the soft magnetic high silicon steel ultra-thin strip, and make the raw materials meet the following alloying element mass percentages:

[0037] C: 0.006%, Si: 6.5%, Mn: 0.15%, S: 0.025%, Nb: 0.04%, Co: 0.28%, P: 0.003%, N: 0.009% and the balance of Fe;

[0038] b. First add the high-silicon steel base alloy into the high-vacuum arc melting furnace, and smelt at 1150 ° C. After the high-silicon steel base alloy is safely melted, smelt 3 times repeatedly. The cobalt-iron-silicon alloy continues to be smelted, and the smelting temperature is 1100 °C, and smelting is repeated for 3; then the high-silicon steel thin strip precursor is prepared by using a single vacuum roll (copper roll) strip, wherein the surface line speed of the copper r...

Embodiment 2

[0044] A preparation method of a soft magnetic high silicon steel ultra-thin strip, comprising the following steps:

[0045] a. Take high-silicon steel parent alloy, niobium-iron alloy and cobalt-iron-silicon alloy as raw materials for preparing the soft magnetic high silicon steel ultra-thin strip, and make the raw materials meet the following alloying element mass percentages:

[0046] C: 0.005%, Si: 6.2%, Mn: 0.12%, S: 0.02%, Nb: 0.02%, Co: 0.23%, P: 0.004%, N: 0.008% and the balance of Fe;

[0047] b. First add the high-silicon steel base alloy into the high-vacuum arc melting furnace, and smelt at 1190 ° C. After the high-silicon steel base alloy is safely melted, smelt 4 times repeatedly. The cobalt-iron-silicon alloy continued to be smelted at a temperature of 1150°C and smelted 4 times; then the high-silicon steel thin strip precursor was prepared by stripping a single vacuum roll (copper roll), wherein the surface speed of the copper roll was 30m / s, the degree of va...

Embodiment 3

[0053] A preparation method of a soft magnetic high silicon steel ultra-thin strip, comprising the following steps:

[0054] a. Take high-silicon steel parent alloy, niobium-iron alloy and cobalt-iron-silicon alloy as raw materials for preparing the soft magnetic high silicon steel ultra-thin strip, and make the raw materials meet the following alloying element mass percentages:

[0055] C: 0.0065%, Si: 6.9%, Mn: 0.18%, S: 0.03%, Nb: 0.05%, Co: 0.32%, P: 0.003%, N: 0.01% and balance Fe;

[0056] b. First add the high-silicon steel base alloy into the high-vacuum arc melting furnace, and smelt at 1250 ° C. After the high-silicon steel base alloy is safely melted, smelt 5 times repeatedly. The cobalt-iron-silicon alloy continued to be smelted at a temperature of 1200°C, and smelted 5 times; and then the high-silicon steel thin strip precursor was prepared by stripping with a single vacuum roll (copper roll), wherein the surface speed of the copper roll was 40m / s, the degree of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com