Environment-friendly and energy-saving air film building

An air-membrane building, environmental protection and energy-saving technology, which is applied to buildings, building types, tents/canopies, etc., can solve the problems of poor snow removal effect and inability to apply the air-membrane building body, etc., to achieve overall convenience in use, improve snow removal effect, and save money. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

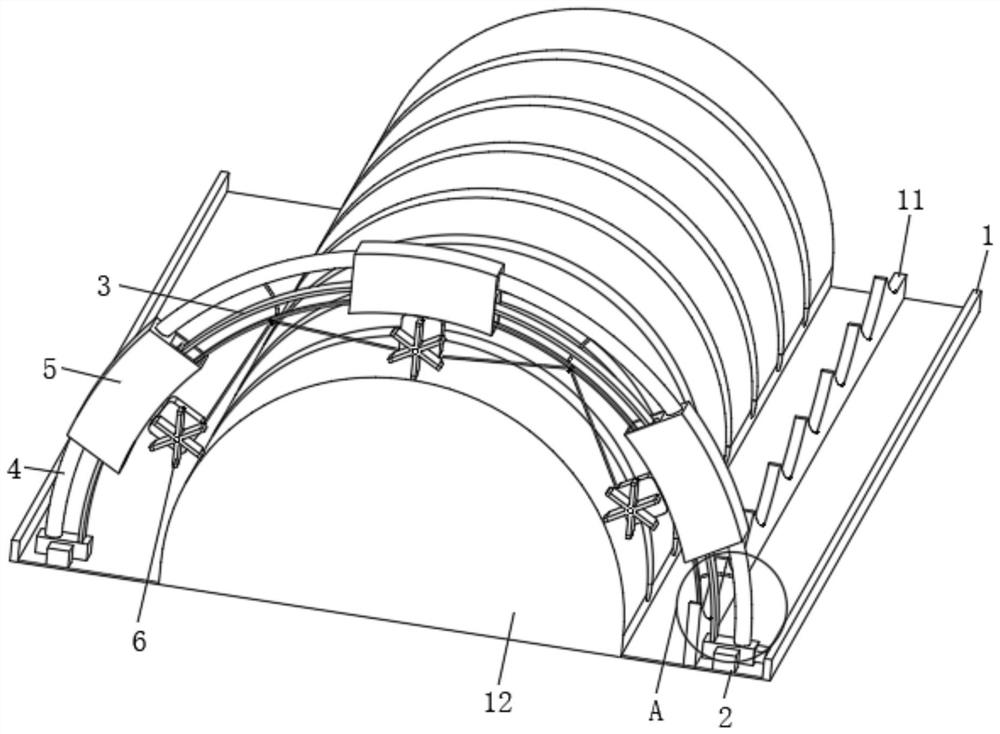

[0034] see Figure 1 to Figure 4 , Figure 9 , the embodiment of the present invention provides an environment-friendly and energy-saving air-film building: comprising an air-film building body 12, the air-film building body 12 is an existing mature technology, and will not be described in detail here; the left and right sides of the air-film building body 12 are The base 1 is fixedly installed, and the two bases 1 are jointly provided with a drive assembly 2, and the first inflatable sleeve 4 is detachably connected to the drive assembly 2. The first inflatable sleeve 4 is an inflatable product made of PVC sandwich material and Oxford fabric. When the first Under the action of the driving assembly 2, the inflatable sleeve 4 is adapted to the shape of the air film building body 12 after being inflated.

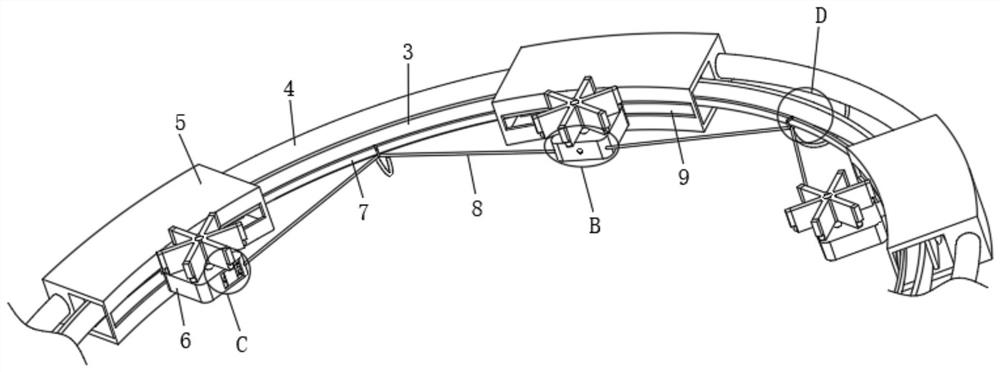

[0035] The outer surface of the first inflatable sleeve 4 is fixedly installed with N shells 5 arranged in a circular array. In this embodiment, there are an odd number of th...

Embodiment 2

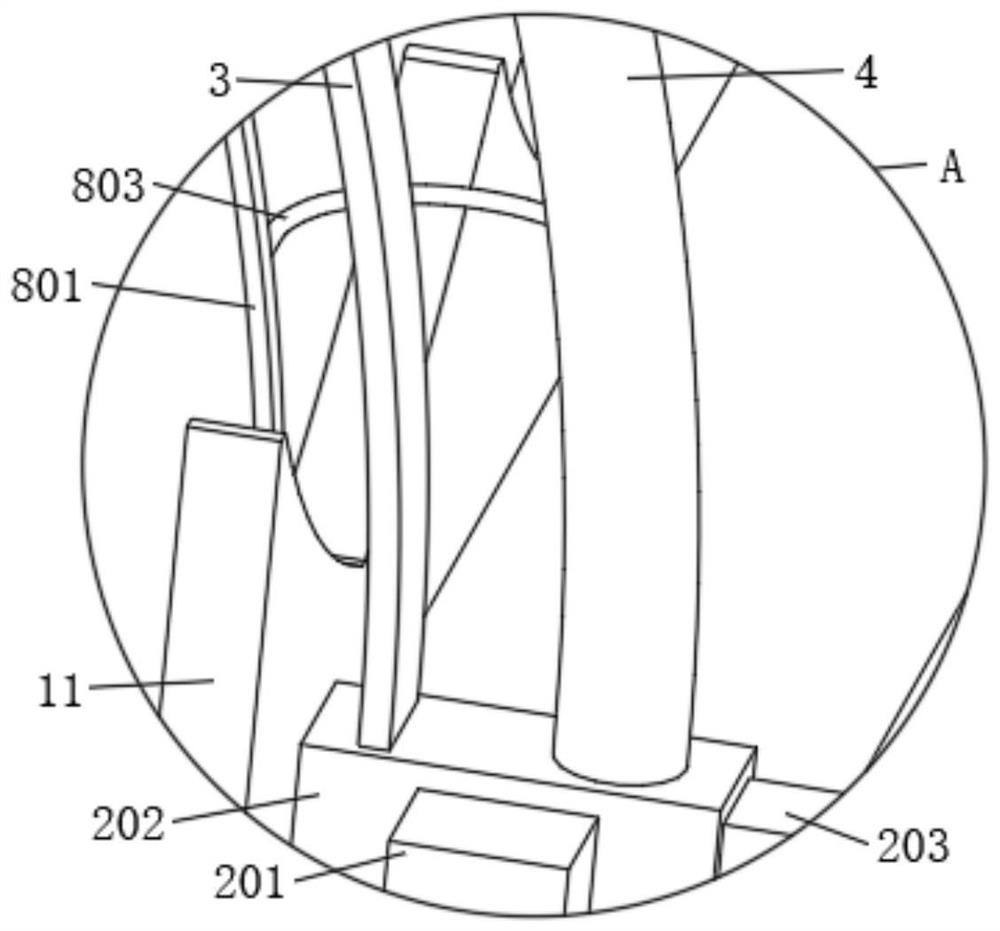

[0039] see Figure 1 to Figure 9 , on the basis of Embodiment 1, the driving assembly 2 includes cylinders 201 fixedly installed on the two bases 1, and the movable ends of the two cylinders 201 are fixedly installed with detachable connections with the first inflatable sleeve 4 and the support assembly 3. The air guide block 202, the two ends of the first inflatable sleeve 4 are respectively connected with the two air guide blocks 202, and the surface of one of the air guide blocks 202 is connected with an air pump 203, which is used to send air to the air guide block 202, and The gas guide block 202 can deliver gas to the first inflatable sleeve 4 and the support assembly 3 .

[0040] The support assembly 3 includes a first hose 301 detachably connected to the air guide block 202, the two ends of the first hose 301 are respectively connected to the two air guide blocks 202, and the upper surface of the first hose 301 is fixedly installed with There are top plates 302 equal ...

Embodiment 3

[0047] see Figure 1 to Figure 10 , on the basis of the second embodiment, the bottom of the housing 5 is penetrated with an arc-shaped groove 9, the slider 601 is set as an I-shaped slider 601, and the I-shaped slider 601 is slidably installed inside the arc-shaped groove 9, and the I-shaped The length of the slider 601 is relatively large, that is, the I-shaped slider 601 can slide along the arc groove 9, and can also slide up and down relative to the arc groove 9 without falling off from the arc groove 9; the connecting pipe 305 is The telescopic hose provides feasibility for the I-shaped slide to slide along the arc groove 9.

[0048] A synchronous assembly 8 is provided between the N housings 5, and the synchronous assembly 8 includes N-1 crossbars 802. The crossbars 802 are U-shaped and arranged between two adjacent housings 5. 701 is drawn out from the cover plate 702 and fixedly connected to the adjacent block 602 through the corresponding cross bar 802, and the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com