Atomization frequency tracking and water level detection system of atomization sheet

A technology of atomizing sheet and frequency tracking, which is applied in air humidification system, heating and ventilation control system, heating and ventilation safety system, etc. It can solve the problems of high production cost, poor anti-interference ability and low sensitivity, and achieve manufacturing cost Low, easy-to-achieve, high-sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

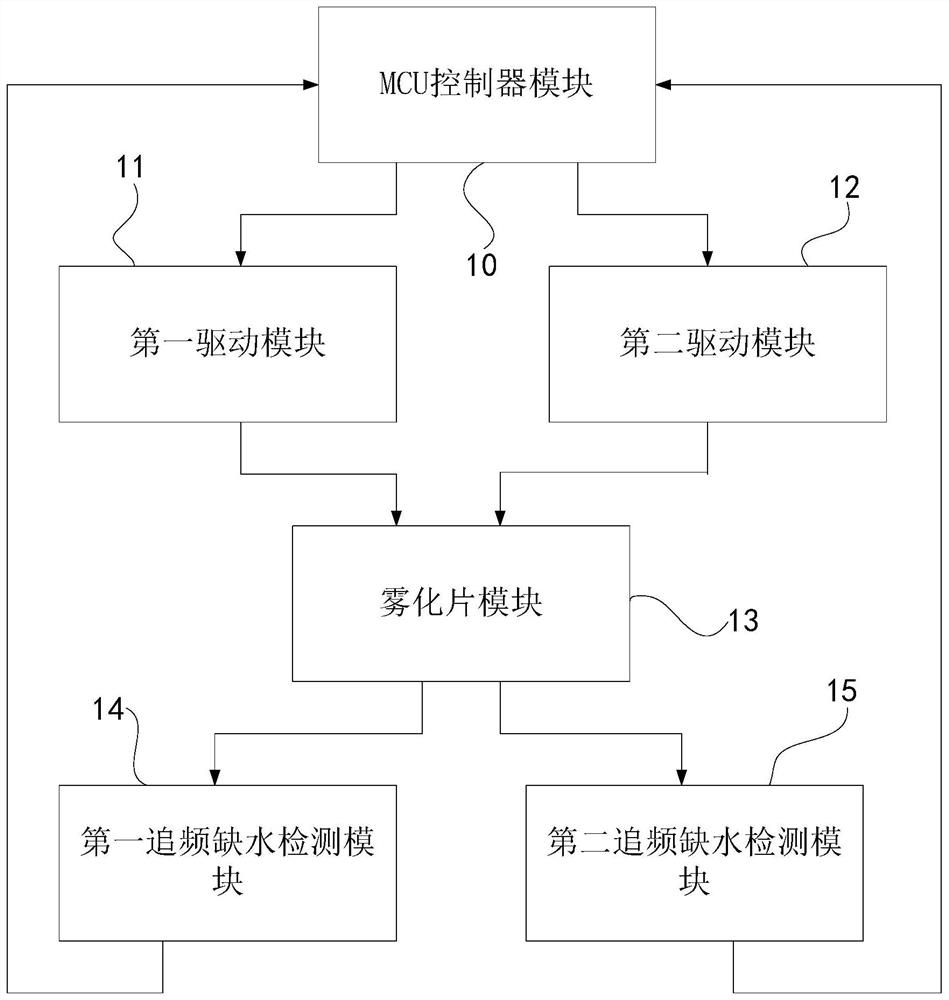

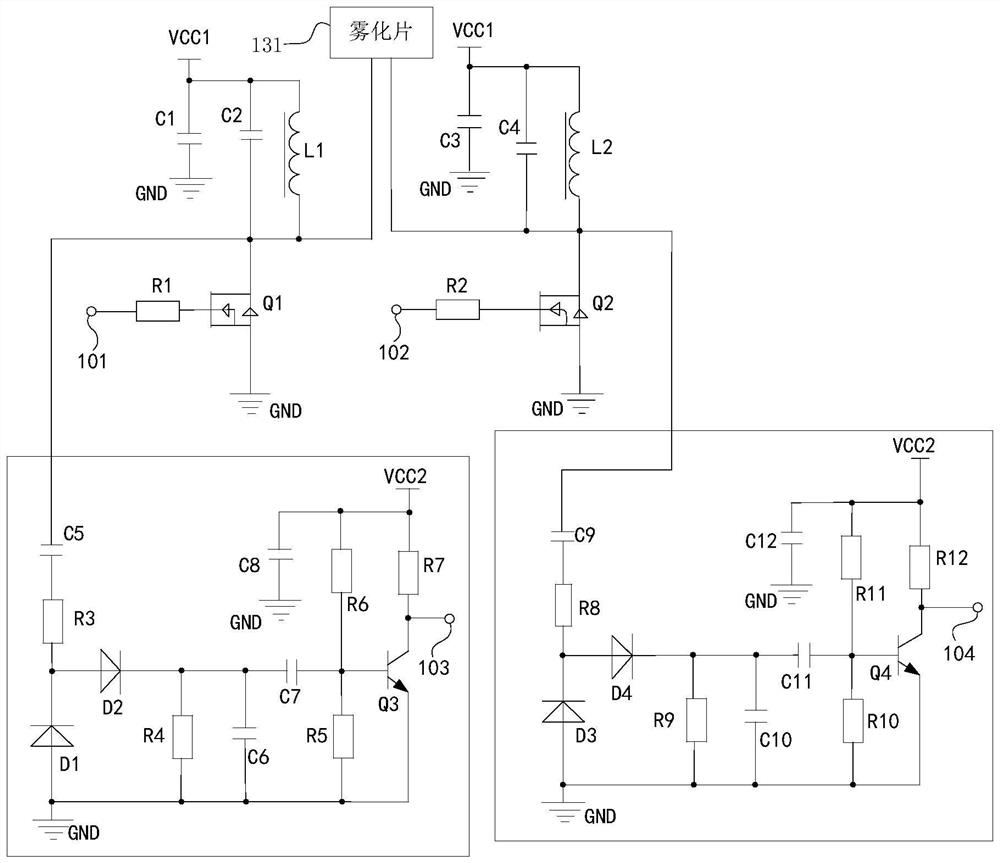

[0017] see figure 1 The atomization frequency tracking and water level detection system of the atomization sheet disclosed in the present invention includes an MCU controller module 10, a first drive module 11, a second drive module 12, an atomization sheet module 13, a first frequency tracking water shortage detection module 14 and the second frequency tracking water shortage detection module 15.

[0018] The MCU controller module 10 is used to output the first PWM driving signal and the second PWM driving signal. It should be understood that the difference between the frequency ranges of the first PWM driving signal and the second PWM driving signal in this embodiment is no more than 2 MHz in the natural frequency of the atomizing sheet.

[0019] The first driving module 11 is used for amplifying the first PWM driving signal to obtain a first amplified signal.

[0020] The second driving module 12 is used for amplifying the second PWM driving signal to obtain a second ampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com