Cement woven bag cleaning equipment

A technology for cleaning equipment and woven bags, which is applied in the field of construction engineering, can solve problems such as lowering work efficiency, flying cement particles, unfavorable recycling of woven bags, etc., and achieves the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

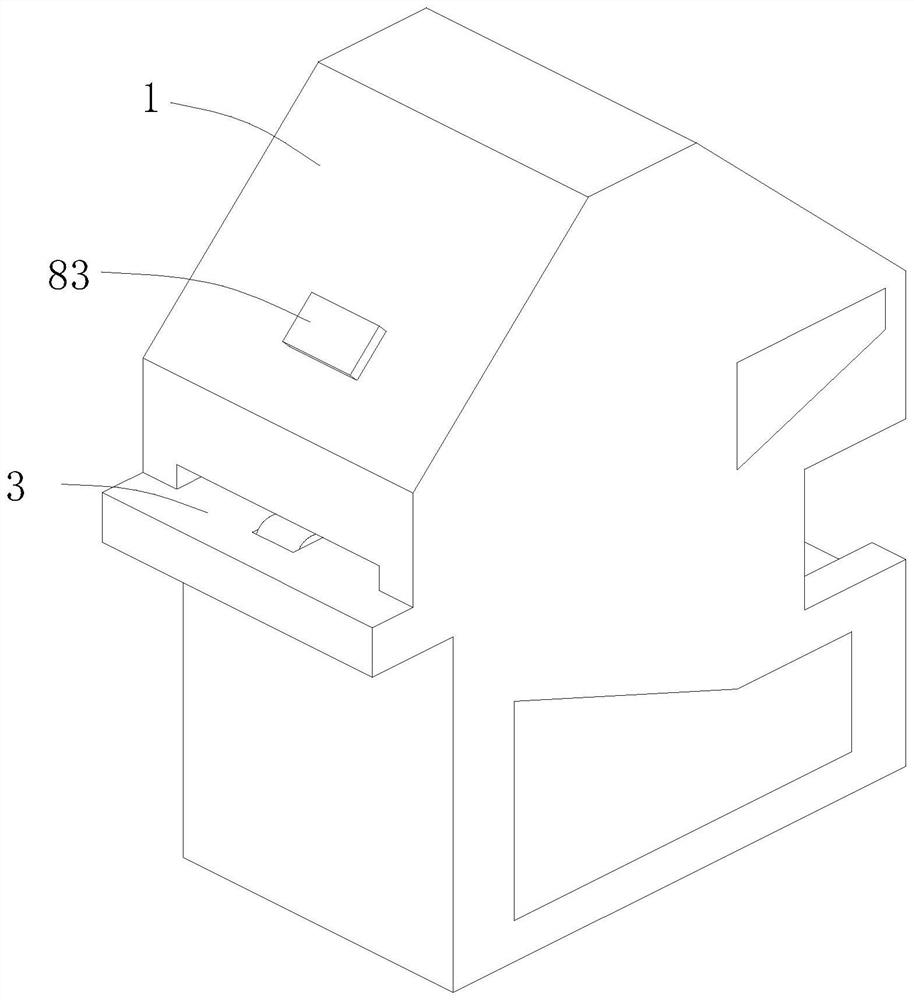

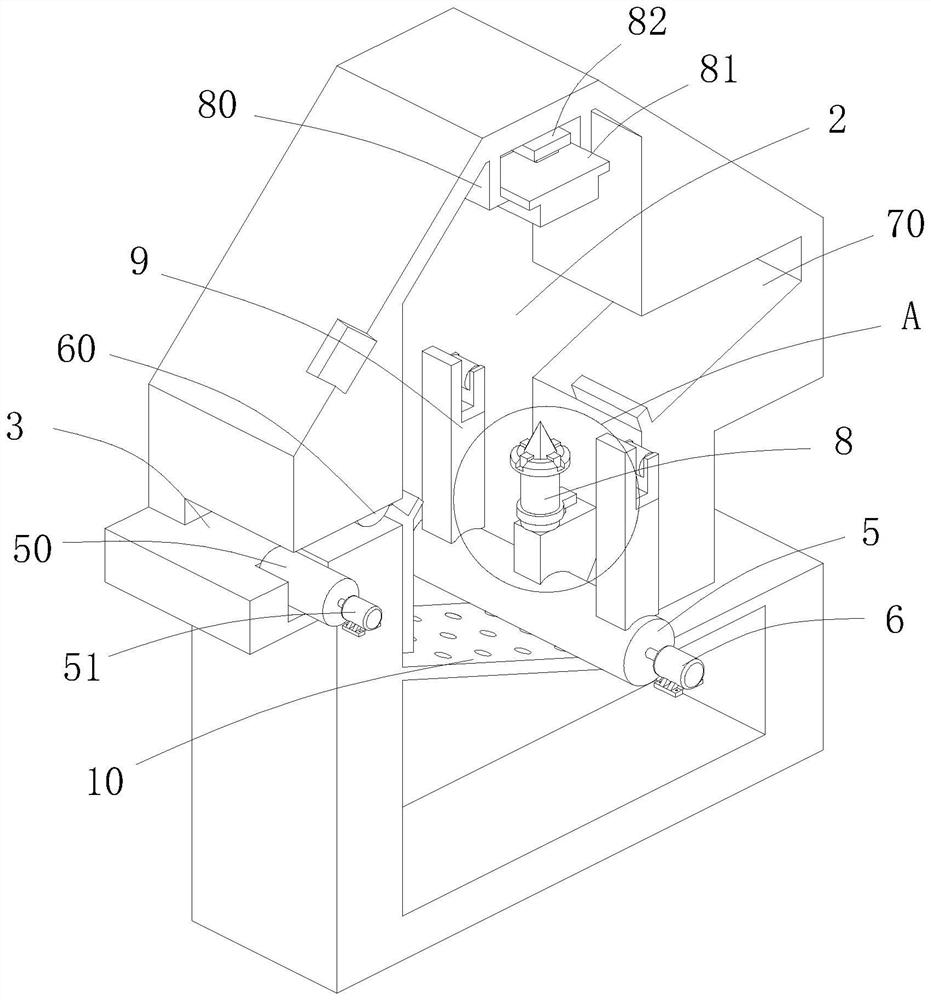

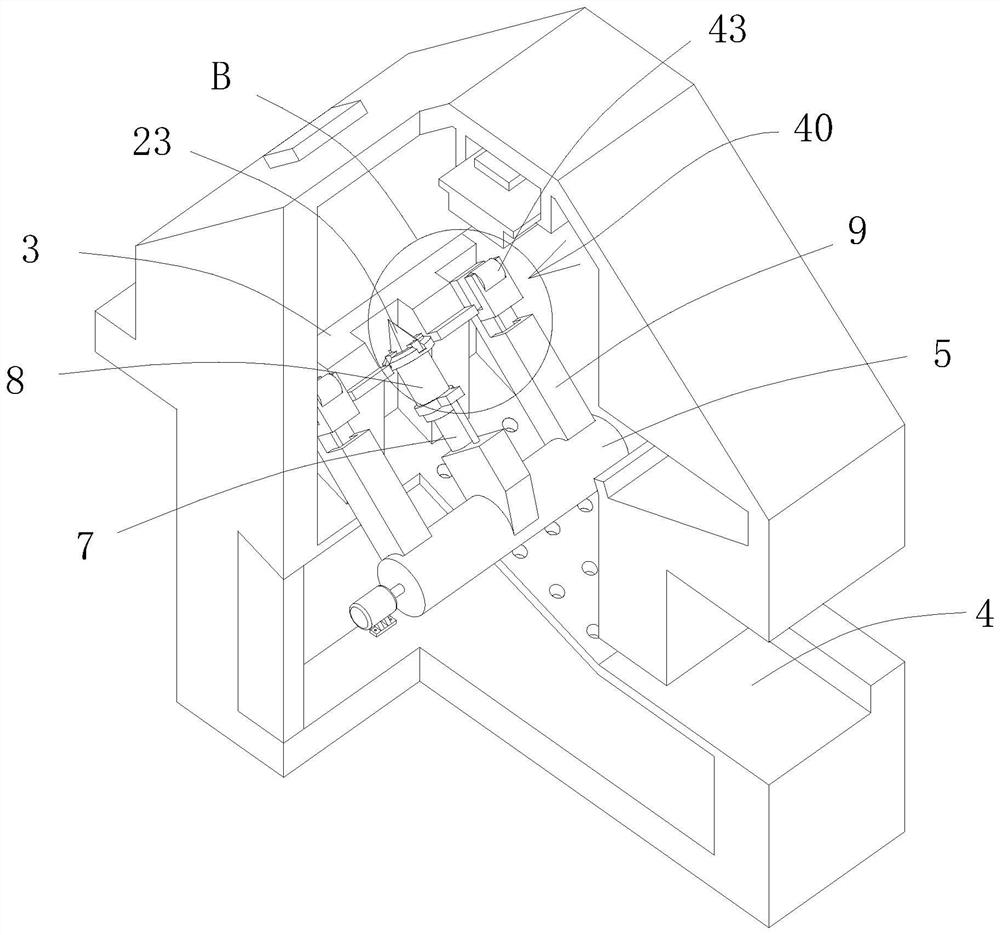

[0028] A cement woven bag cleaning equipment, such as Figure 1 to Figure 3 As shown, including the case 1, the case 1 is provided with a working chamber 2, the left and right ends of the case 1 are respectively provided with an input channel 3 and a discharge channel 4 communicating with the working chamber 2, the right end of the input channel 3 is provided with a slope, and the right end of the slope is provided There is a baffle plate to prevent the woven bag from slipping, the middle of the working chamber 2 is connected with a swing rod 5 for rotation, the first motor 6 for driving the swing rod 5 to rotate is arranged in the cabinet 1, an air outlet pipe 7 is arranged in the middle of the swing rod 5, and the bottom of the air outlet pipe 7 The pipeline connected with an external air compressor, the top of the air outlet pipe 7 can discharge high-press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap