Automatically adjustable and controllable scraper system and control method thereof

An automatic adjustment and scraper technology, applied in the direction of additive manufacturing, additive processing, etc., can solve the problem that the scraper cannot be adjusted adaptively, and achieve the effect of reducing the adjustment time of the scraper, avoiding equipment damage, and responding quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

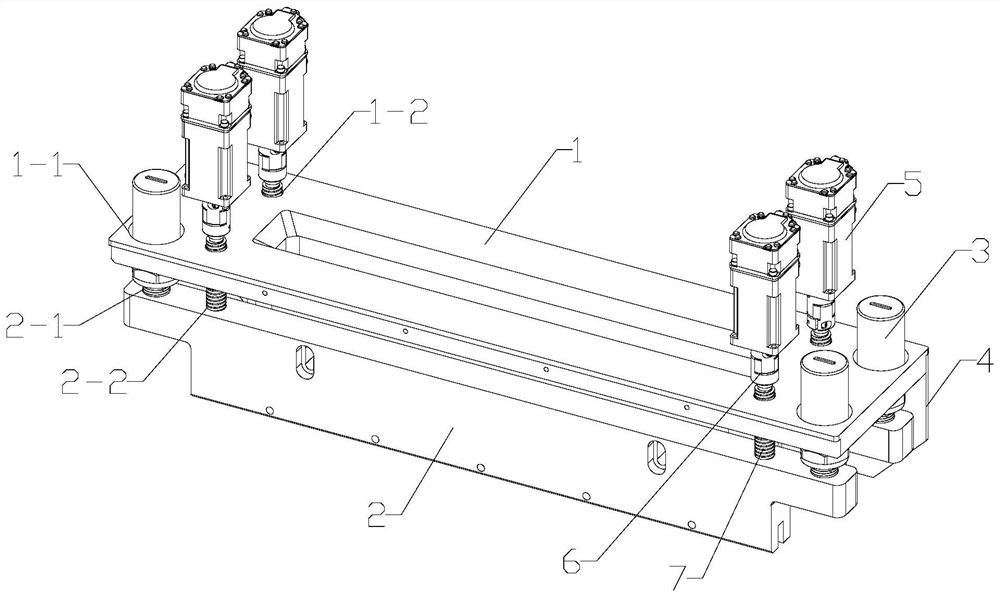

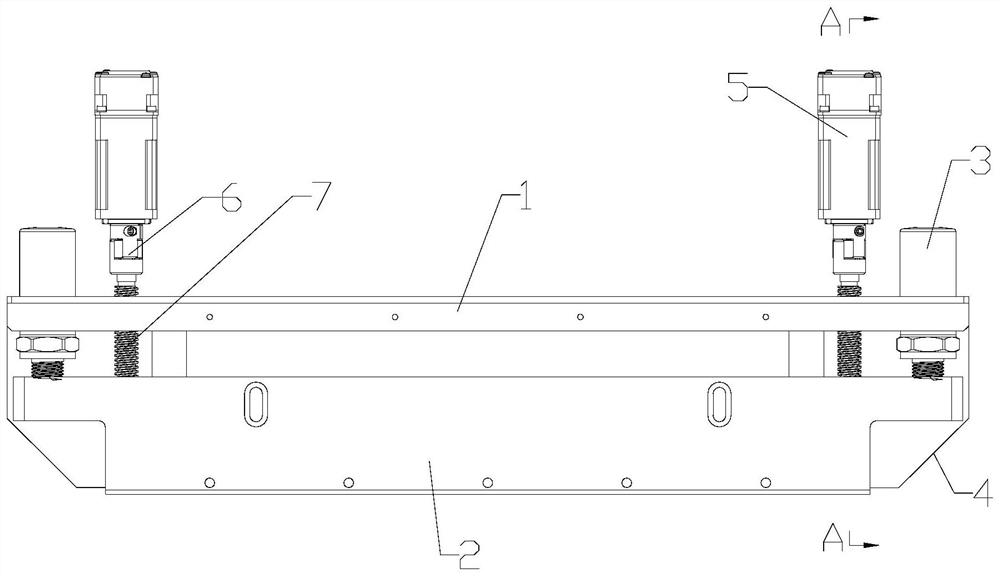

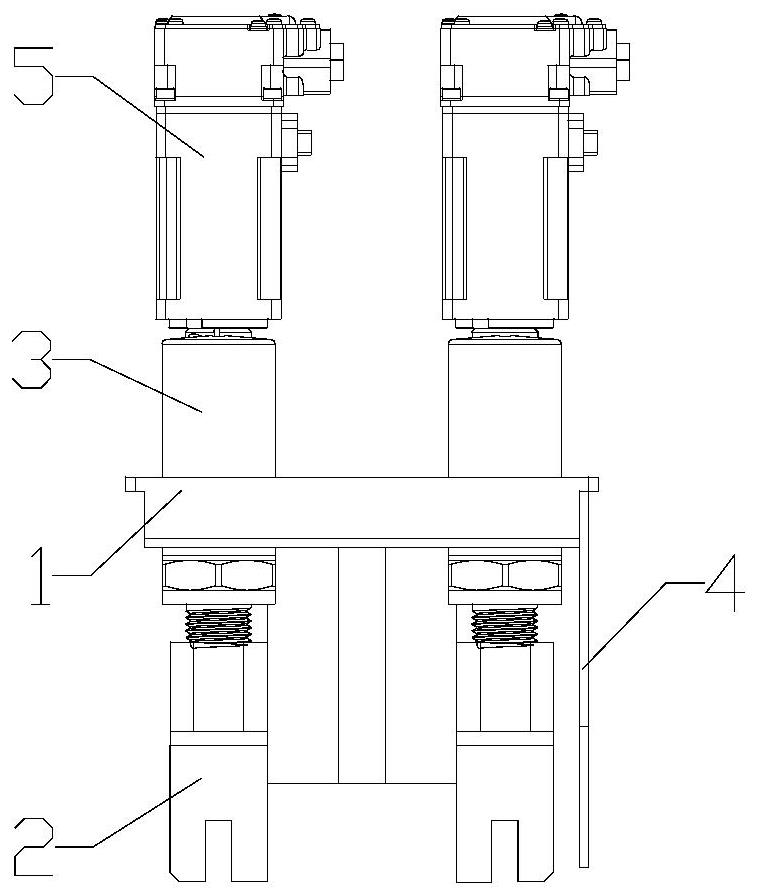

[0029] see Figure 1 ~ Figure 4 (In order to better demonstrate the internal structure, one of the dust-proof cover plates is not shown), the embodiment of the present invention provides an automatically adjustable and controllable scraper system, including a scraper frame, a scraper holder, a pressure sensor, a height adjustment devices and control modules.

[0030] The middle of the scraper frame is provided with a powder drop port, the bottom of the scraper frame is provided with a structural space for installing a scraper holder, the structural space is provided with a scraper holder, and the top of the scraper holder is vertically powdered Both ends of the direction are connected with a pressure sensor and a height adjustment device, and dust-proof covers are installed on both sides of the scraper frame along the powder-spreading direction, and the dust-proof covers are fixed through screw holes on both sides of the scraper frame. Specifically, both sides of the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com