Fixture for correcting drilling path of drill bit

A fixture and path technology, used in drilling/drilling equipment, manufacturing tools, components of boring machines/drilling machines, etc., can solve the problem of inability to guarantee the processing size, and achieve the effect of stable path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

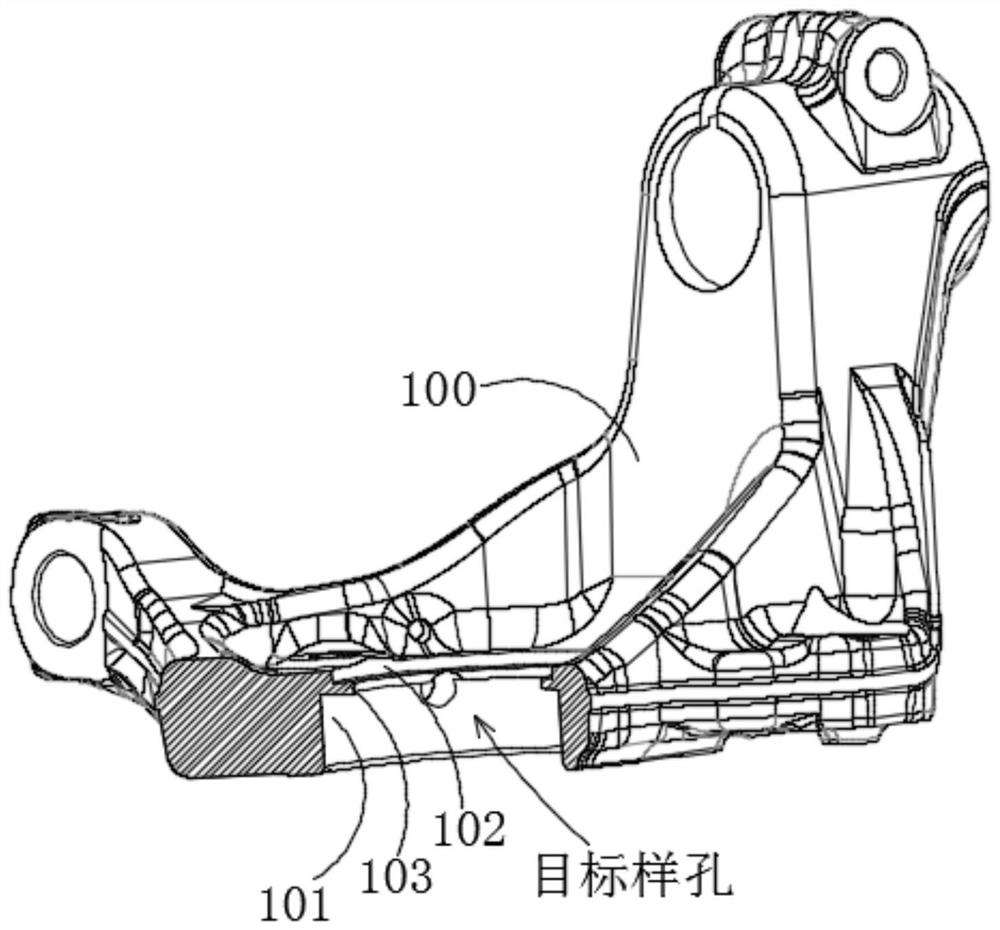

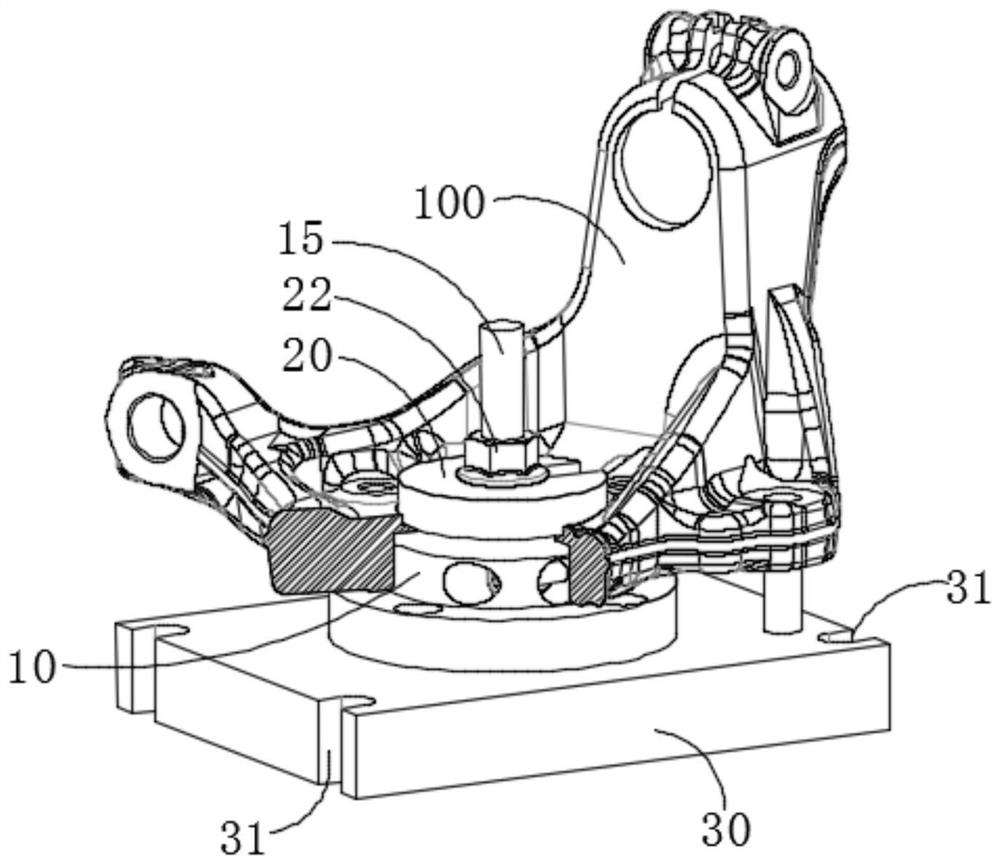

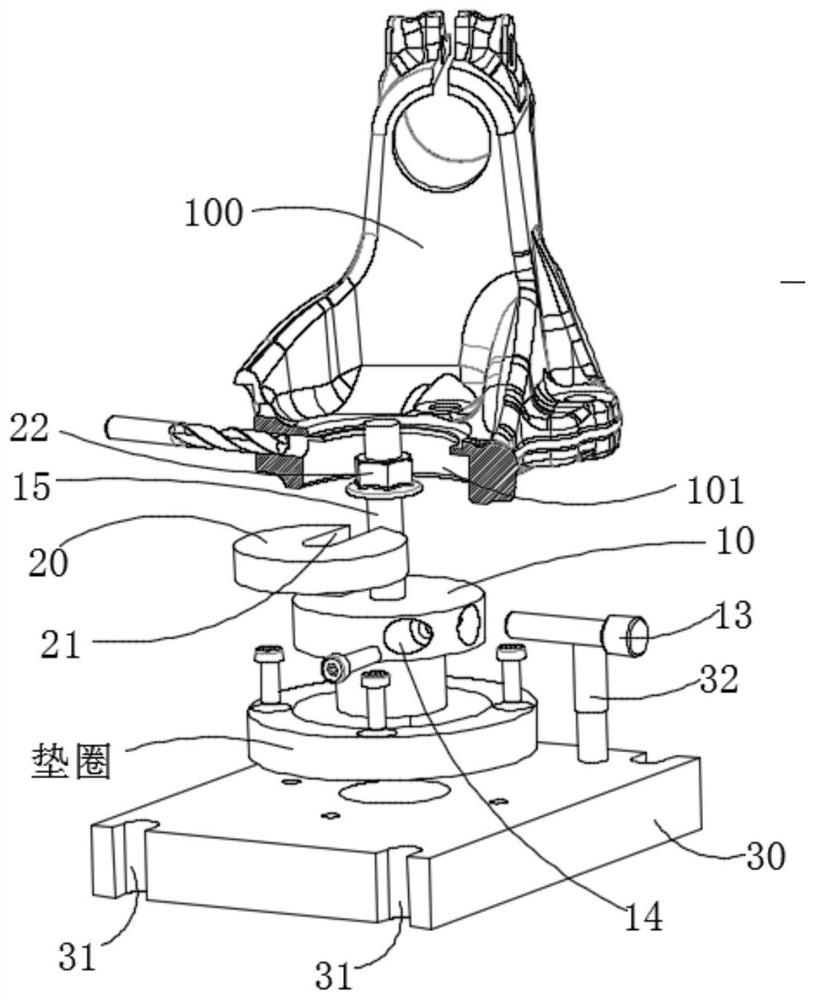

[0029] This embodiment provides a drill bit drilling path correction jig, the correction jig is mounted on the steering knuckle, when the steering knuckle is drilled, the needle roller 13 in the correction jig is used to pair the tool (that is, the alloy drill bit) Provide support to prevent the unilateral force on the drill bit during cutting and drilling, and the downward deviation of the drill bit will cause the deviation of the processing size of the steering knuckle.

[0030] In this program, see Figure 2-Figure 6 , the provided drill drilling path correction jig needs to be fixed with the steering knuckle 100 to facilitate the drilling operation of the alloy drill on the steering knuckle; specifically, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com