High-altitude falling prevention track and manufacturing method thereof

A technology for anti-falling and rails, applied in safety belts, life-saving equipment, etc., can solve the problems of low strength, difficult transportation and installation, poor anti-theft performance, etc., achieve good tensile strength and deflection resistance, realize zero loss, and be universal strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

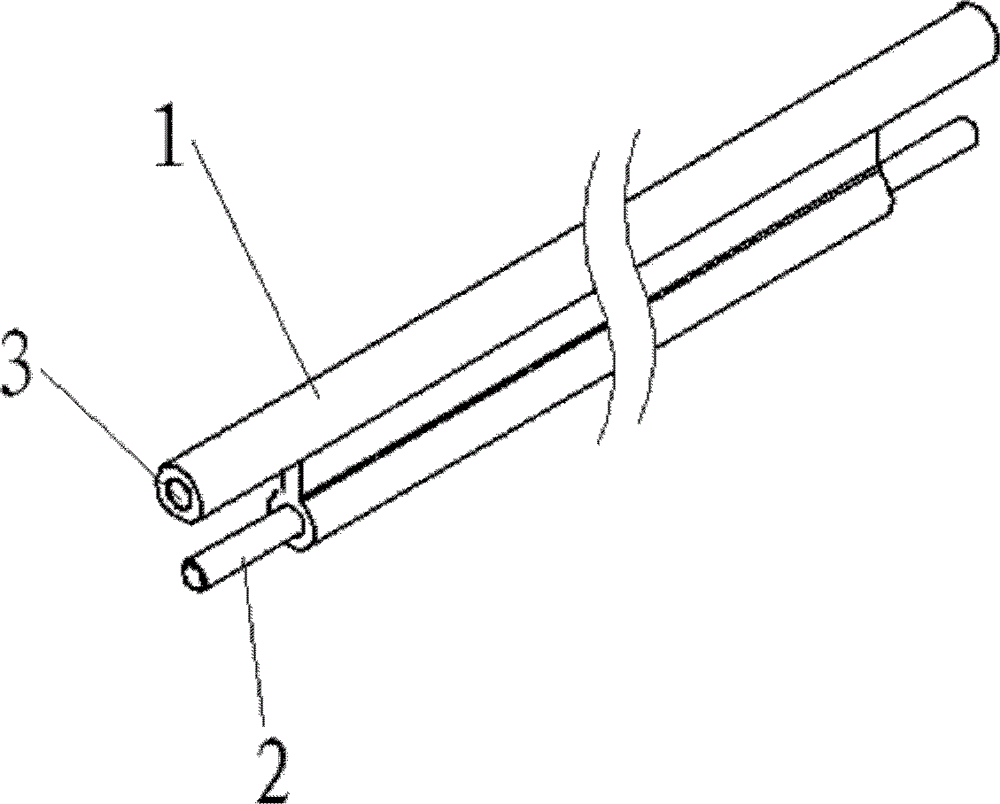

[0026] Such as Figure 1 to Figure 3 As shown, it is the first embodiment of the high-altitude fall prevention track of the present invention. The high-altitude fall prevention track of this embodiment includes a track body made of aluminum alloy profile 1. The extended steel wire hole 3 is used to set the steel wire 2. The steel wire 2 is set in the steel wire hole 3. The steel wire 2 and the aluminum alloy profile 1 are closely combined. Profile 1, so that the aluminum alloy profile 1 is tightly wrapped on the outside of the steel wire 2, the steel wire 2 and the aluminum alloy profile 1 are tightly combined, and the steel wire 2 cannot escape from the aluminum alloy profile 1.

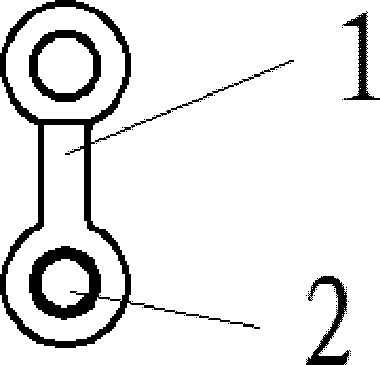

[0027] see image 3 , in this embodiment, two steel wires 2 are compounded in the aluminum alloy profile 1, and the cross section of the aluminum alloy profile 1 is roughly in the shape of an "8", including two circular parts and a connecting part connecting the two circular parts, Each circular p...

Embodiment 2

[0031] Such as Figure 4 As shown, it is the second embodiment of the high-altitude fall prevention track of the present invention. In this embodiment, the cross section of the aluminum alloy profile 1 is "L-shaped", and the aluminum alloy profile 1 is compounded with three steel wires 2, as shown in the figure As shown, the upper end of the vertical part of the "L"-shaped section, the right end of the horizontal part, and the intersection of the vertical part and the horizontal part are respectively provided with steel wire holes, and a steel wire 2 is compounded in each steel wire hole. The composite structure of the aluminum alloy profile 1 and the steel wire 2 in this implementation is the same as that of the first embodiment, and will not be repeated here.

Embodiment 3

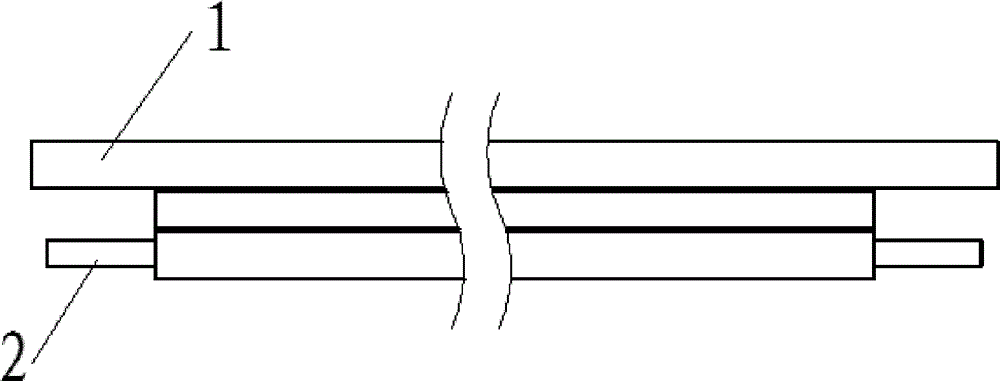

[0033] Such as Figure 5 As shown, it is the third embodiment of the high-altitude fall prevention track of the present invention. In this embodiment, the cross section of the aluminum alloy profile 1 is "I" shape, and two steel wires 2 are compounded in the aluminum alloy profile 1, such as As shown in the figure, steel wire holes are respectively provided at the junction of the vertical part of the "I" shape and the two horizontal parts, and a steel wire 2 is compounded in each steel wire hole. In this implementation, the aluminum alloy profile 1 and the steel wire 2 are combined The structure is the same as that of the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com