Waste bin transferring and welding sealing system

A waste barrel and welding sealing technology, which is applied in the direction of hollow objects, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing occupational health risks and low work efficiency, and achieve the goals of reducing radiation risks, improving work efficiency, and improving safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

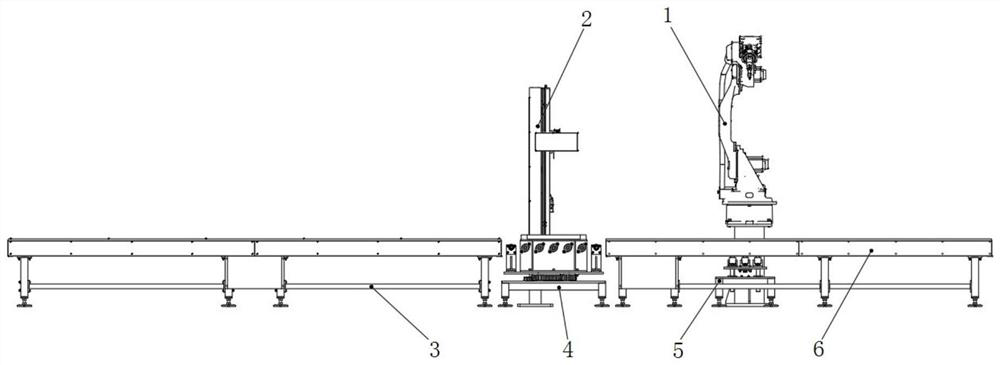

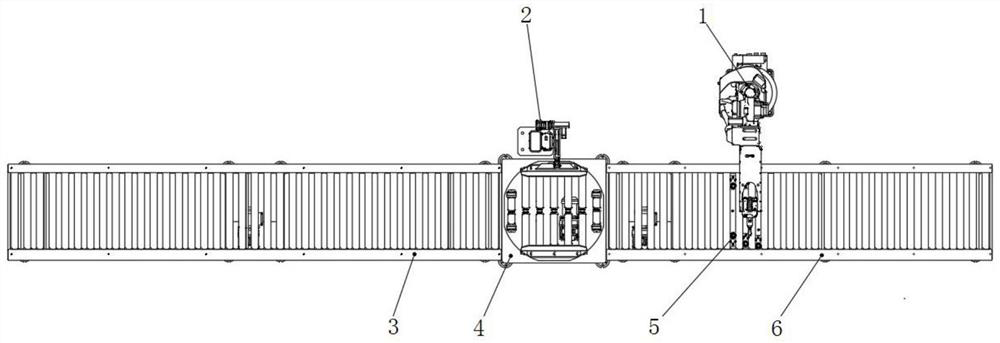

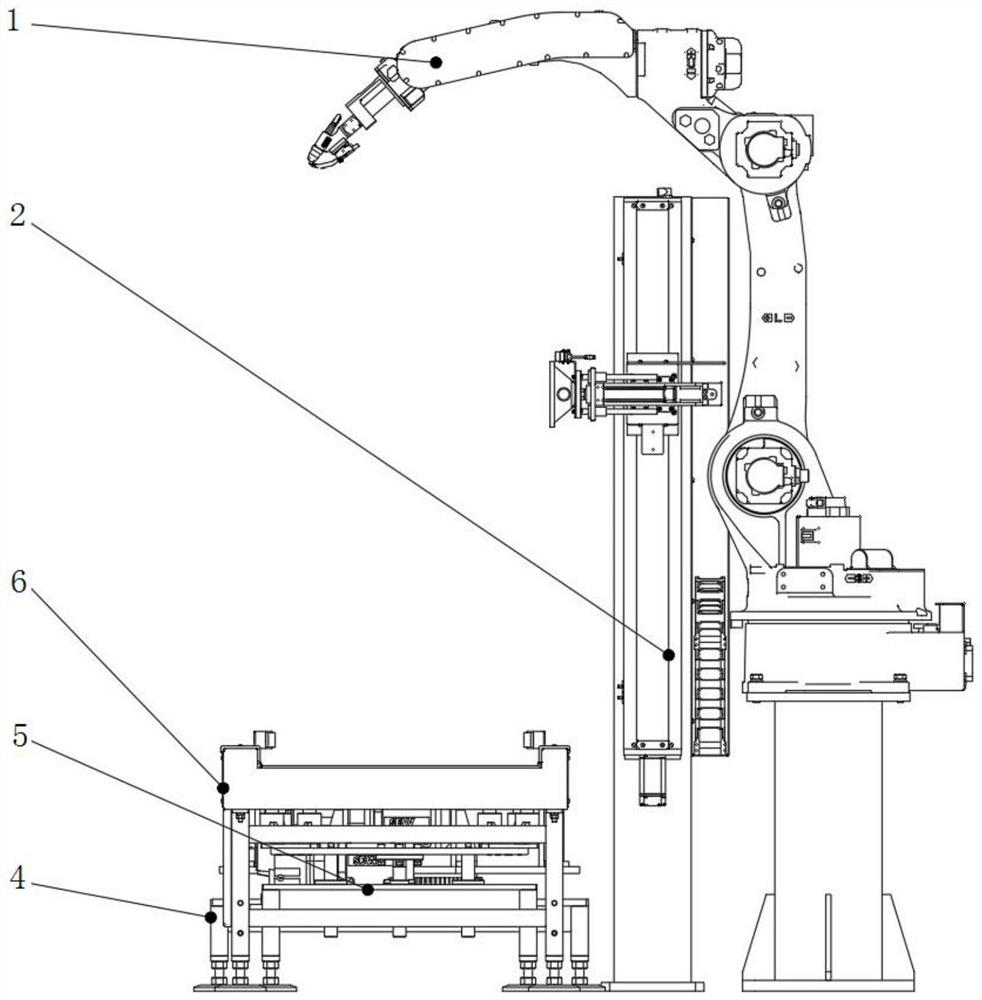

[0035] Such as figure 1 , figure 2 , image 3 As shown, this embodiment discloses a waste barrel transfer and sealing system, including a transfer device, a welding device 1, a detection device 2, and a rotating device 4, wherein:

[0036] The transfer device is used to transport the waste barrel, which includes a barrel-entry roller table 6 and a barrel-exit roller table 3;

[0037] The welding device 1 is arranged at the adjacent position of the barrel-entry roller table 6, and is used to weld the gap between the barrel body and the bucket cover of the waste barrel conveyed on the barrel-entry roller table 6 (that is, welding and sealing);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com