Clamping mechanism

A technology of clamping mechanism and guiding structure, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of single structural design principle and inability to adjust the clamping size adaptively, so as to prevent bumps and scratches, novel structural design, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

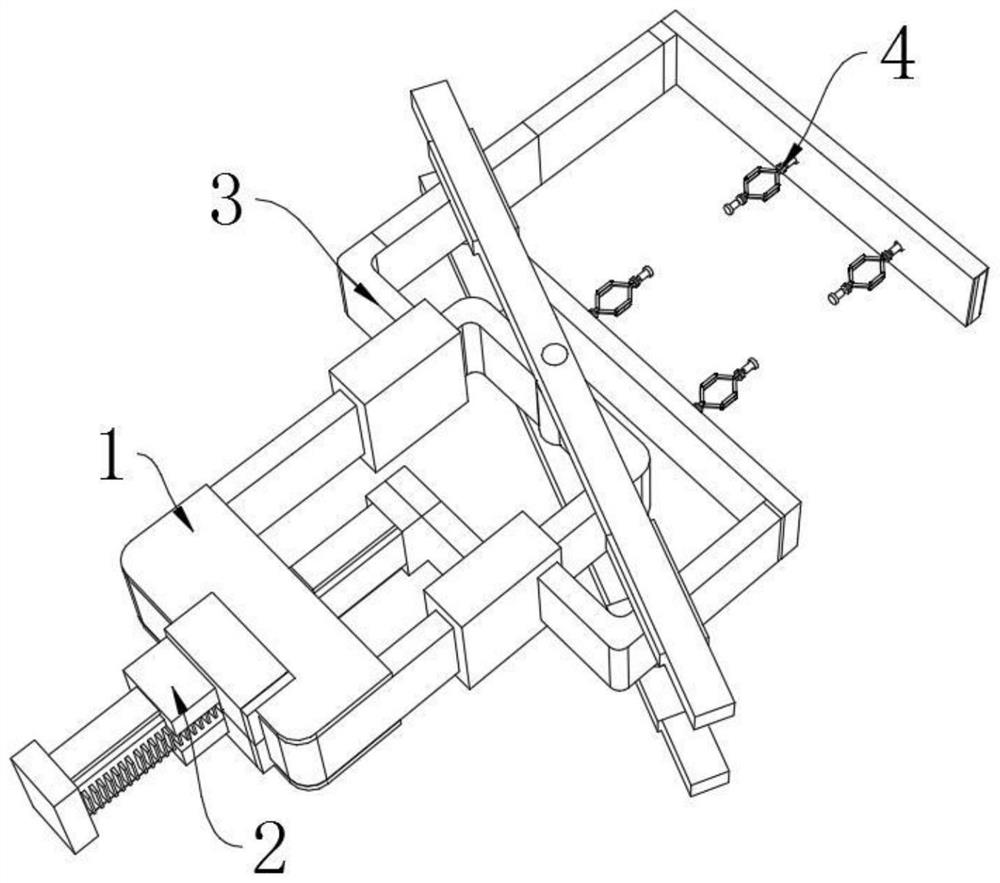

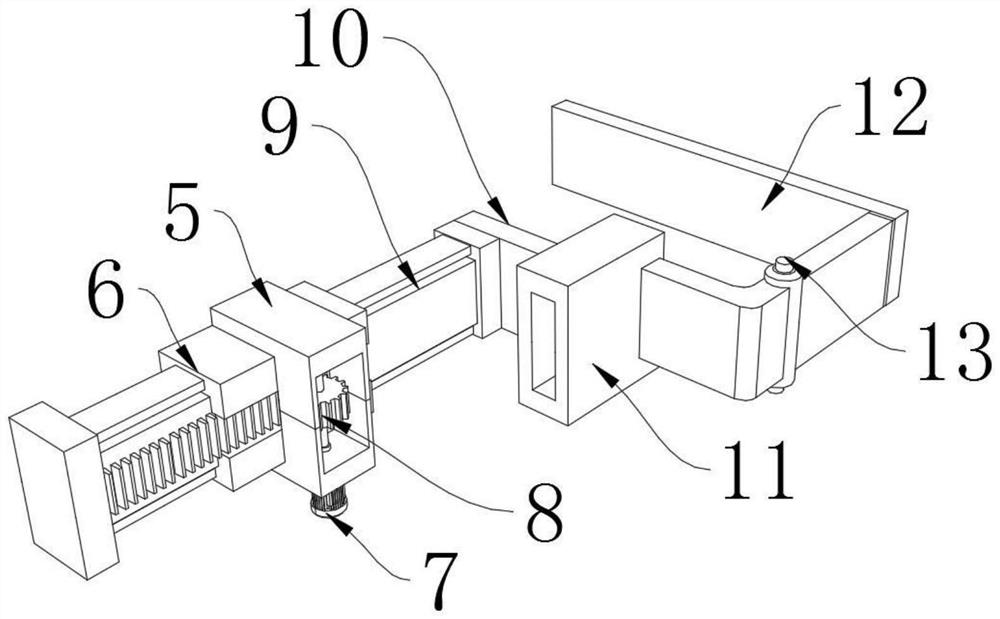

[0027] like Figure 1-5 A clamping mechanism of the present invention is shown, including a two-way guiding structure 1, an active clamping structure 2 and a driven clamping structure 3,

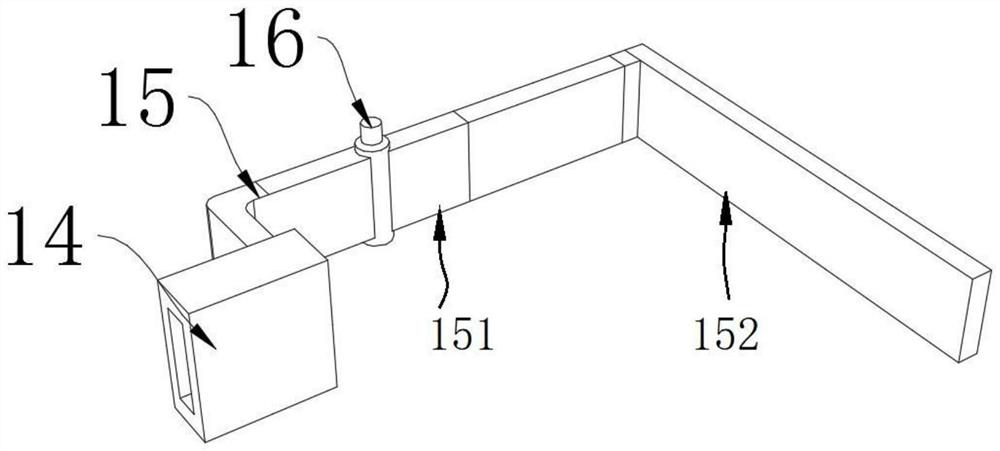

[0028] The two-way guide structure 1 includes a fixed base 17, a first slide rail 18 and a second slide rail 19 arranged in parallel on one side of the fixed base 17, and a second slide rail 19 is arranged between the first slide rail 18 and the second slide rail 19. Center pin 20, the top and the bottom of center pin 20 are all rotatably connected with offset linkage rod 21, and the inside of one end of two offset linkage levers 21 is all slidingly provided with active connecting block 22, and the inside of the other end is all slidingly provided with driven connection block 23,

[0029] The active clamping structure 2 includes a driving device and a first sliding guide block 11, the first sliding guiding block 11 is slidably connected with the second sliding rail 19, and the driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com