Impeller clearance adjusting device of slurry pump

A gap adjustment device and slurry pump technology, which is applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of time-consuming and laborious adjustment process, difficult operation, and decreased overall efficiency of slurry pump, etc., to achieve fast and convenient adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

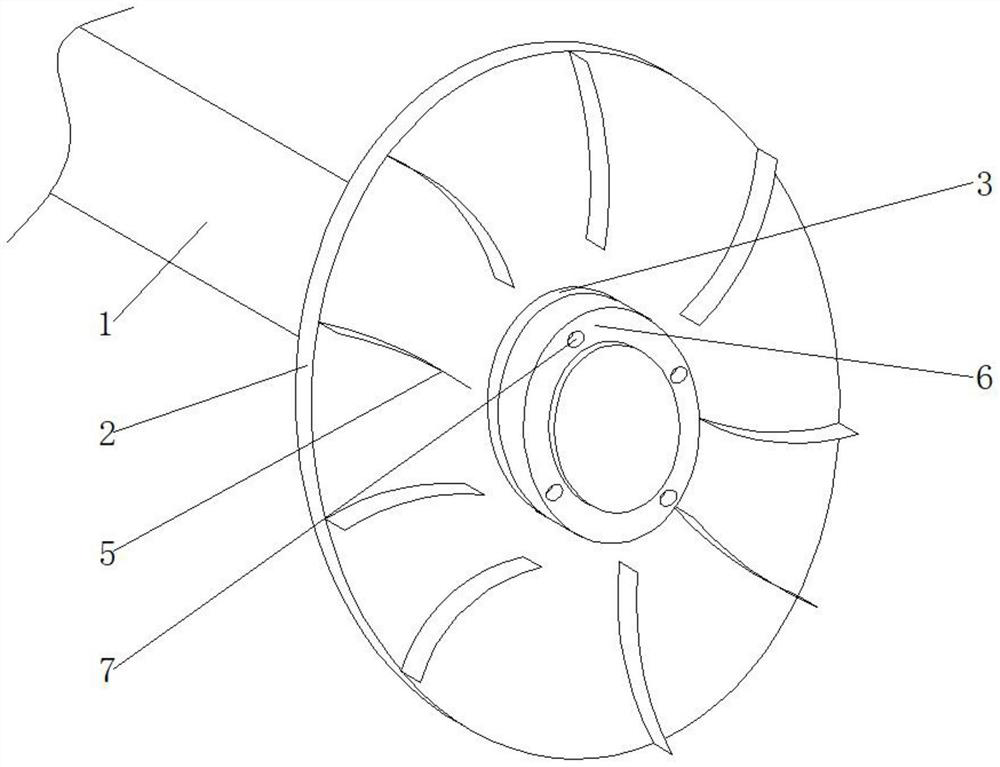

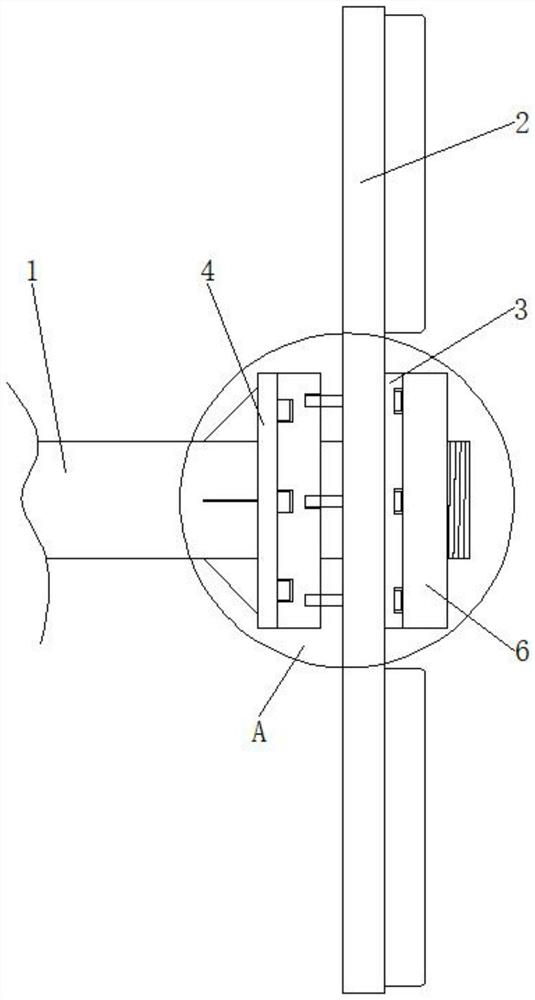

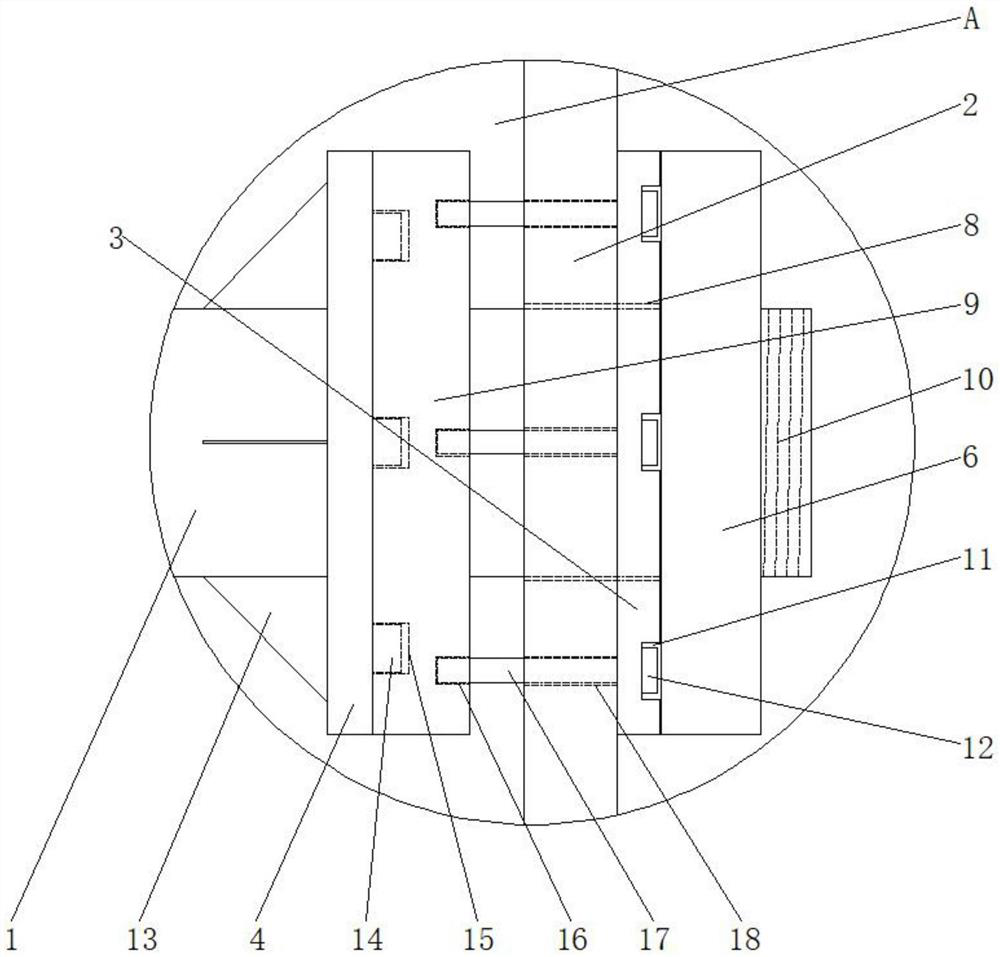

[0030] see Figure 1-7 , the present invention provides a technical solution: a slurry pump impeller 2 clearance adjustment device, including a transmission shaft 1, an impeller 2, a sleeve 3, a counter plate 4 and a wrench 20; the right side surface of the impeller 2 is provided with a blade 5. There are multiple blades 5, and the multiple blades 5 are evenly distributed on the outer ring surface of the impeller 2;

[0031] The impeller 2 is sleeved on the outer ring on the right side of the transmission shaft 1, and the middle surface of the right side of the impeller 2 is fixed with a sleeve 3, and the center surface of the sleeve 3 and the center surface of the impeller 2 are provided with a hole 8, and the sleeve The cylinder 3 is sleeved on the outer ring on the right side of the transmission shaft 1, and the transmission shaft 1 passes through the impeller 2 and the sleeve 3 through the opening 8. The four corners of the surface of the sleeve 3 are provided with grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com