Propeller for propelling ship

A technology for propellers and ships, which is applied to ship propulsion, propulsion components, outboard propulsion devices, etc., and can solve problems such as low speed, damage, loss of power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

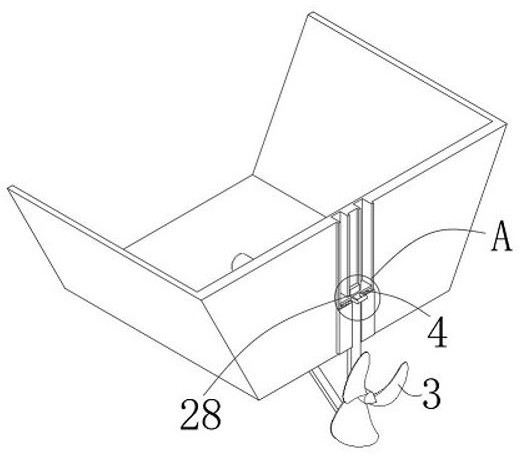

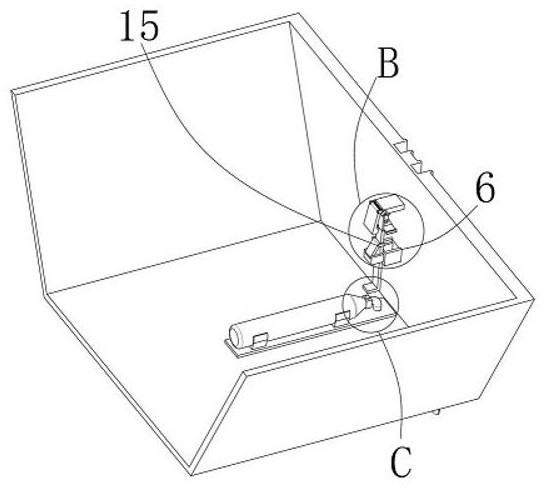

[0032] See image 3 , Image 6 , Figure 8 , Figure 9 and Figure 11 The present invention provides a propeller for protecting the propeller to the ship to avoid the loss of the ship, including the push rod 1, and the push rod 1 is provided in the outer side of the hull, the outer side of the hull, the outer side of the hull The propeller 2 is slidable with the push rod 1, the push rod 1 is provided with a propulsion propeller 3, and the upper end of the push rod 1 is provided with a boost assembly 4, the auxiliary mechanism 5, and the auxiliary mechanism 5 is provided on the bottom side of the hull. The inside of the hull is provided with a trigger mechanism 6.

[0033]The trigger mechanism 6 includes a trigger frame 7 and a clamping bidirectional screw 8, the trigger frame 7 is provided inside the hull, and two support block 9 are provided outside the trigger frame, and the two support block 9 is provided inside Turn the cylindrical 10, the clamping bidirectional screw 8 rotates to ...

Embodiment 2

[0040] See figure 1 , image 3 , Figure 4 , Figure 6-9 and Figure 11 The present embodiment further illustrates the first embodiment, and the present invention provides a propeller for protecting the propeller to the ship to avoid the loss of the ship to avoid the damage of the ship, including push rod 1, pushed forward 1 is provided on the outside of the hull, and the outer side of the hull is opened to the push rod 1, and the push rod 1 is provided with a propulsion propeller 3, and the upper end of the push rod 1 is provided with a boost assembly 4, auxiliary mechanism 5, The auxiliary mechanism 5 is provided on the bottom side of the hull, and the trigger mechanism 6 is provided inside the hull.

[0041] Here, the lifting assembly 4 includes two lifting block 25, and the two holes 25 are fixed to both sides of the pushed rod 1, and two elevated ribs are slidably connected to two lifting blocks 25, respectively. 26. The lower side of the lifting block 25 is provided with a lifti...

Embodiment 3

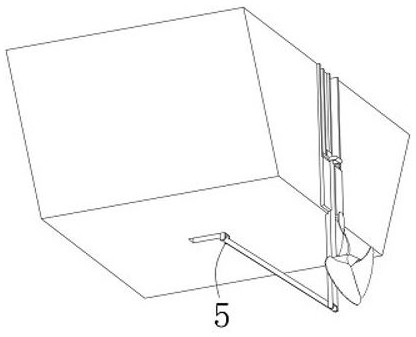

[0046] See figure 2 , Figure 5 and Figure 10 The present embodiment further illustrates the second embodiment, the present invention provides a propeller for automatically collecting propeller when impacting, avoiding impact damage to the throttle, including push rod 1, push rod 1 is provided on the outside of the hull, and the outer side of the hull is opened to the push rod 1, and the push rod 1 is provided with a propulsion propeller 3, and the upper end of the push rod 1 is provided with a boost assembly 4, auxiliary mechanism 5, The auxiliary mechanism 5 is provided on the bottom side of the hull, and the trigger mechanism 6 is provided inside the hull.

[0047] Wherein, the auxiliary mechanism 5 includes auxiliary rod 35 and a communication pipe 36 that opens a helper 37 that is slidably coupled to the auxiliary rod 35, and the auxiliary groove 37 is provided with auxiliary plate 38, the auxiliary rod 35 distal rotation The deflection lever 39 is connected, the deflection le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com