Post-cast strip supporting device for constructional engineering

A technology for construction engineering and support devices, which is applied to the on-site preparation of building components, construction, building construction, etc., and can solve the problems of inconsistent connection structure location and size, increased workload, and inconvenience in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

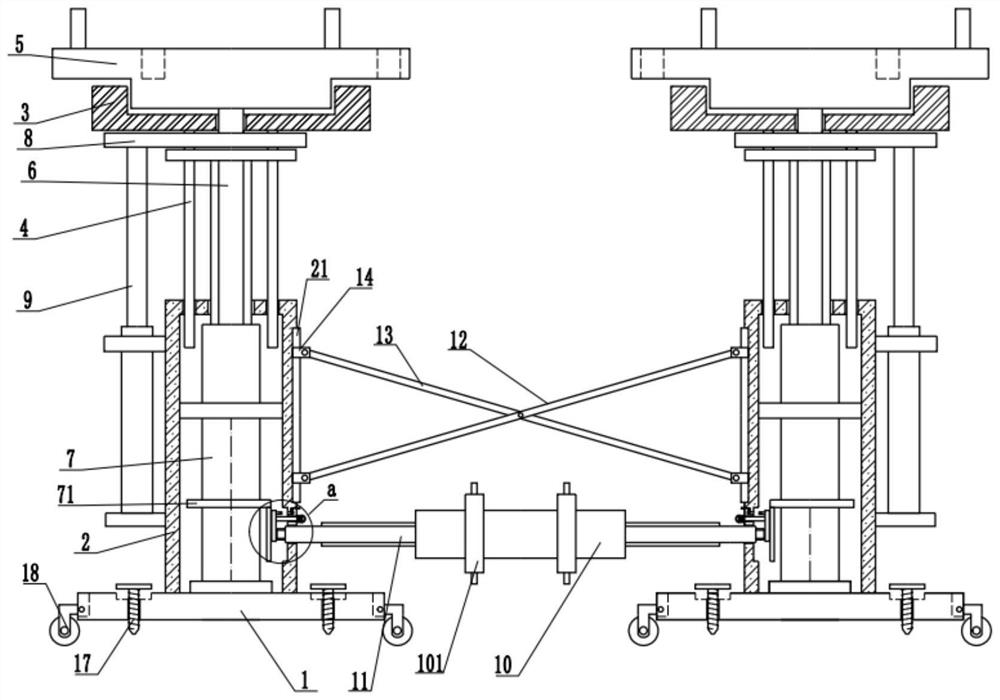

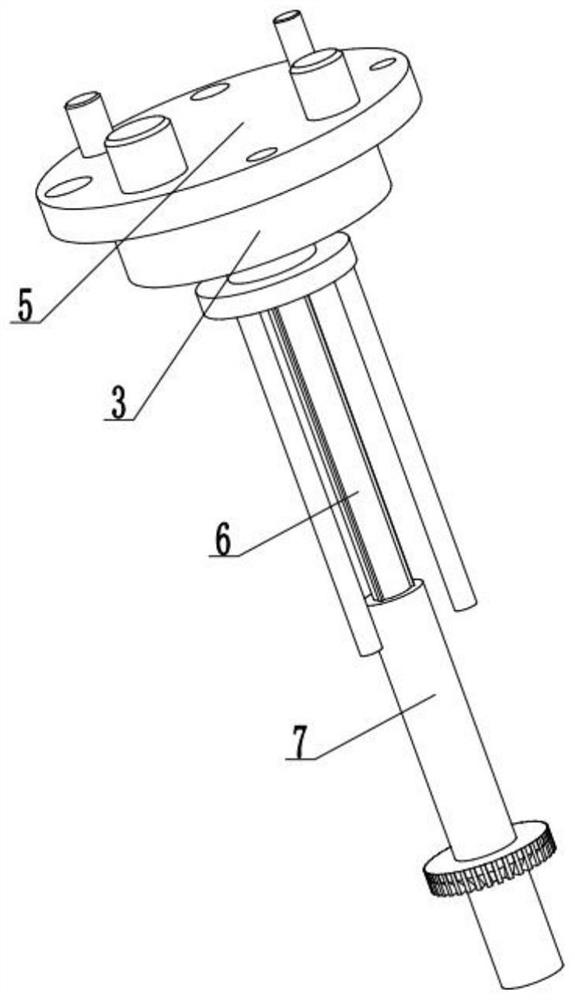

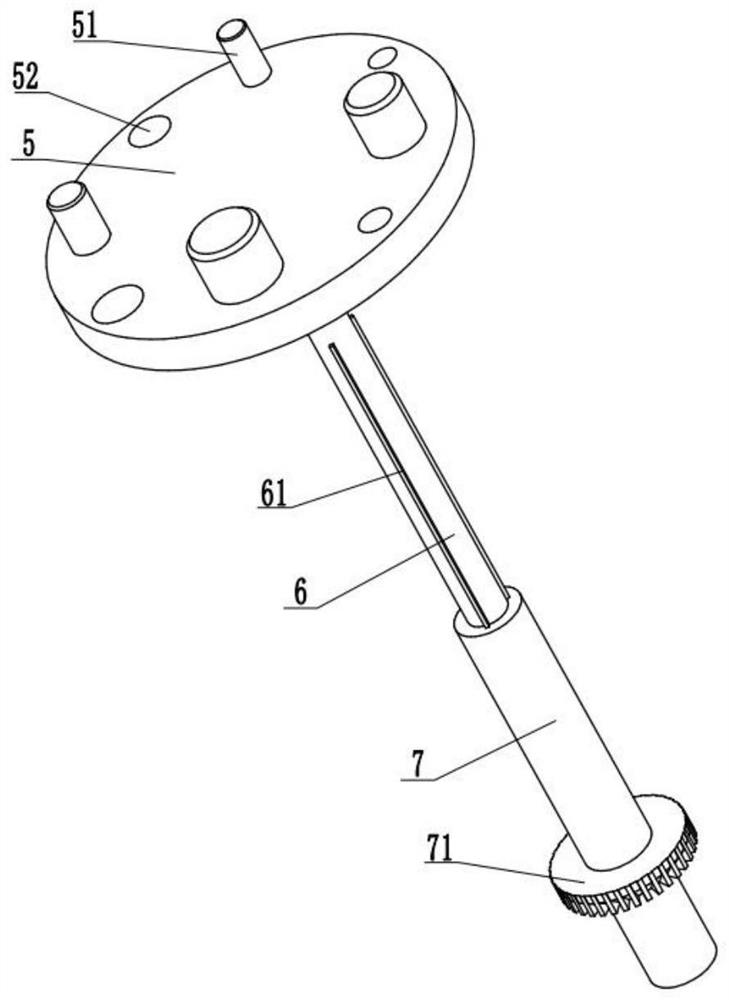

[0023] see Figure 1 to Figure 6 , this embodiment provides a post-cast belt support device for construction engineering, including a base 1, a fixed shell 2, a lifting shell 3 and a hydraulic telescopic rod 9, the fixed shell 2 is installed on the base 1, and the The lifting housing 3 is connected with a hydraulic telescopic rod 9, and the hydraulic telescopic rod 9 is installed on the fixed housing 2. The lifting housing 3 is provided with an installation base 5, and the installation base 5 is provided with several Mounting columns 51 and mounting holes 52 with inconsistent sizes, a support rod 6 is also installed on the mounting base 5, a first rotating tube 7 is installed in the fixed housing 2, and the supporting rod 6 and the first rotating tube 7 plug-in connection, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com