Automatic height measuring device of splitting machine and height measuring method thereof

An automatic height measuring and splitting machine technology, which is applied to measuring devices, optical devices, instruments, etc., can solve problems such as prolonging working time, affecting the feeding stroke of splitting knives, and unable to quickly and accurately measure the thickness of the target object. , to achieve the effect of improving work efficiency, fast and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

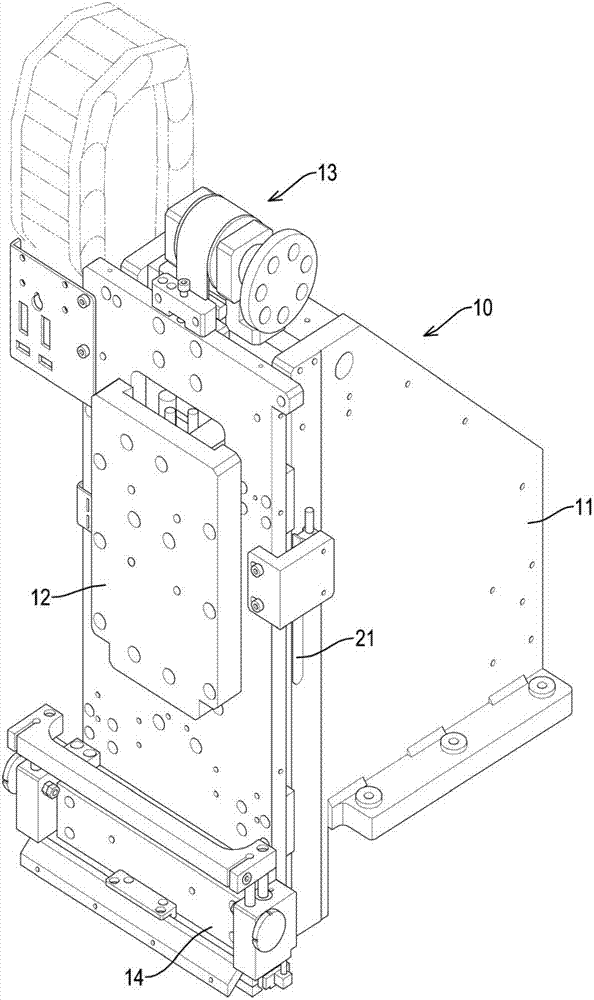

[0034] see Figure 1 to Figure 3 As shown, the automatic height measuring device of the splitting machine of the present invention includes a splitting machine 10, a linear encoder, a position feedback device and a control system.

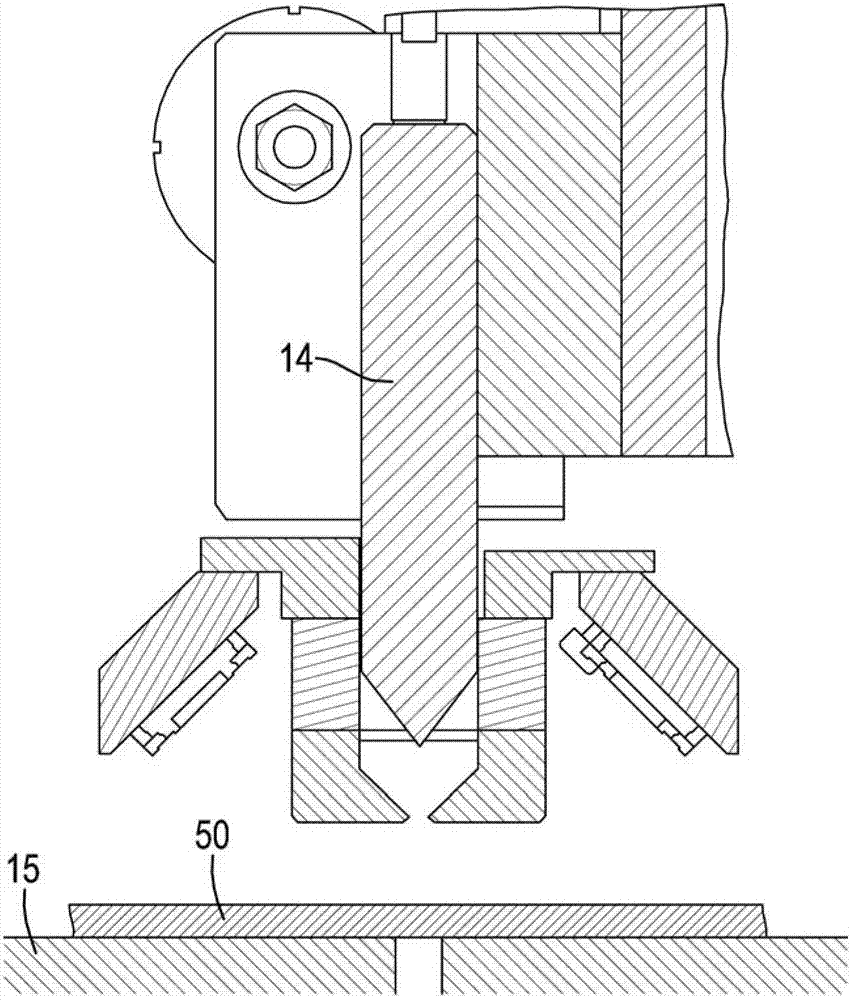

[0035] The aforementioned splitting machine 10 has a base 11, a mobile platform 12, a linear displacement device, a splitting knife 14 and a base 15, and in the present embodiment, the linear displacement device is a linear motor 13; The linear motor 13 is used to control the vertical movement of the mobile platform 12 ; the splitting knife 14 is installed on the mobile platform 12 ; the base 15 is located below the splitting knife 14 .

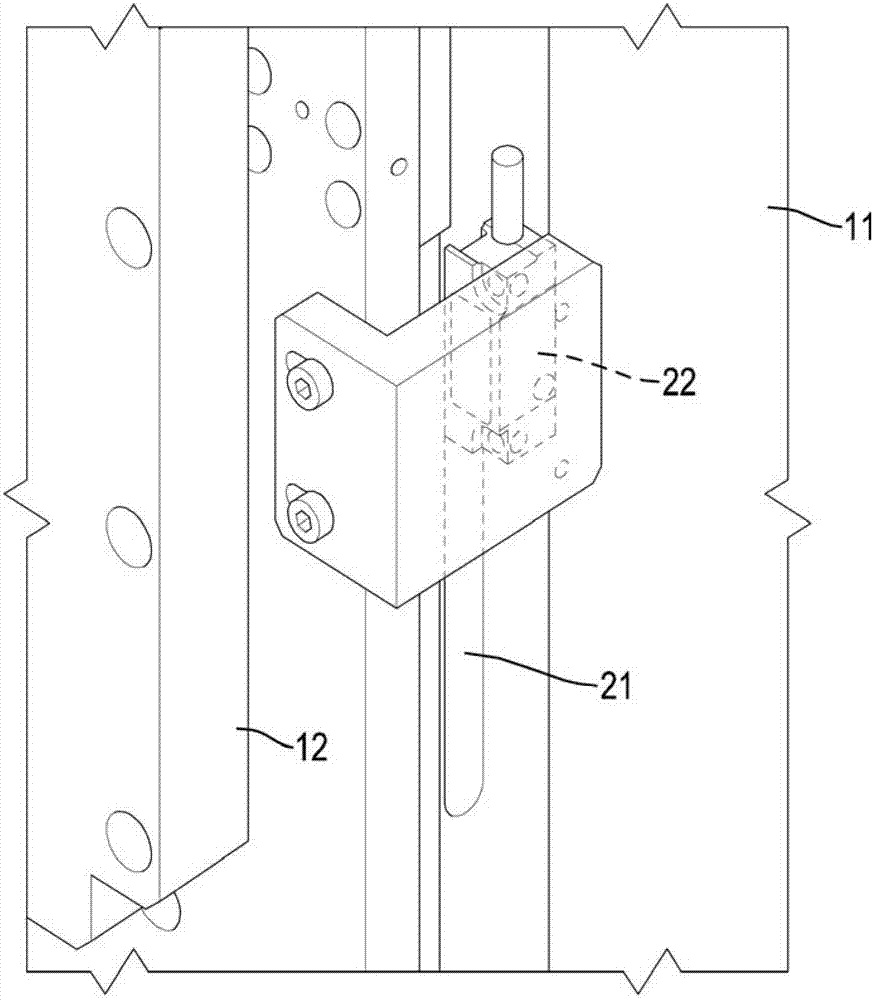

[0036] The aforementioned linear encoder is an optical ruler 21 in this embodiment, which is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com